Preparation method of uranium and impurity element standard substances in triuranium octaoxide

A technology of three uranium octaoxide and impurity elements, which is applied in the field of standard substance preparation, can solve problems such as complex process flow, long preparation time, and pollution of fixed-value elements, and achieve the effects of good process controllability, convenient preparation, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

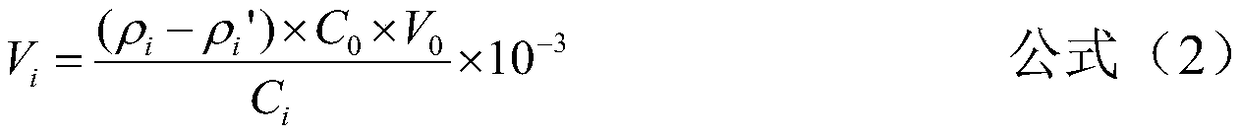

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing standard substances of uranium and impurity elements in triuranium 8 oxide, comprising the following steps:

[0042] Step 1. Fully dissolving the raw material of uranium octaoxide with MOS grade nitric acid to ensure the complete reaction, and obtain a uranyl nitrate solution with a uranium concentration of 500 g / L;

[0043] Step 2: Prepare a solution of fixed value elements, select high-purity metals, oxides or salts without other metals for preparation, the water used is high-purity water, the acid used is MOS grade, the sodium hydroxide is excellent grade pure, and the measuring instruments used are all After verification, the preparation process meets the requirements of the "National Standard for Measurement of Standard Substances";

[0044] Step 3: Filter the uranyl nitrate solution obtained in Step 1 to remove solid insolubles, and measure Si, Fe, K, Na, Th, Pb, Ti, Mo, Cr, Al, Zn, B, Bi, Cd, V, W, Ca, Ni, Mg, Mn, Cu, Zr, Sb, Nb, Ag, Sn el...

Embodiment 1

[0089] Prepare 25 kg of uranium and impurity elements in uranium octaoxide in the analysis of standard materials, the amount of elements to be determined and the expected relative synthetic uncertainty are shown in Table 1-1:

[0090] Table 1-1 Quantity (μg / gU) of undetermined elements and expected relative combined uncertainty (%)

[0091]

[0092] 1 material dissolved

[0093] 1.1 Material selection

[0094] The uranium 8 oxide mineral material of a uranium mining enterprise was selected as the raw material, and its undetermined value content is shown in Table 1-2 below.

[0095] Table 1-2 Element content of undetermined values of raw materials for preparation of UO3O8 candidates

[0096]

[0097] It can be seen from the table that the content of undetermined value elements in the raw materials are all lower than the quantitative value, which meets the technological requirements.

[0098] 1.2 Dissolution

[0099] Considering the preparation process and the sample...

Embodiment 2

[0128] Prepare 25 kg of uranium and impurity elements in uranium octaoxide in the analysis of standard materials, the amount of elements to be determined and the expected relative synthetic uncertainty are shown in Table 1-1:

[0129] Table 1-1 Quantity (μg / gU) of undetermined elements and expected relative combined uncertainty (%)

[0130]

[0131]

[0132] 1 material dissolved

[0133] 1.1 Material selection

[0134] The uranium 8 oxide mineral material of a uranium mining enterprise was selected as the raw material, and its undetermined value content is shown in Table 1-2 below.

[0135] Table 1-2 Element content of undetermined values of raw materials for preparation of UO3O8 candidates

[0136]

[0137]

[0138] It can be seen from the table that the content of undetermined value elements in the raw materials are all lower than the quantitative value, which meets the technological requirements.

[0139] 1.2 Dissolution

[0140] Considering the preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com