Uranium purification method for ammonium biuranate

A technology of ammonium diuranate and a purification method, which is applied in the field of uranium purification of ammonium diuranate, can solve problems such as the limitation of selection of processing and procurement, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

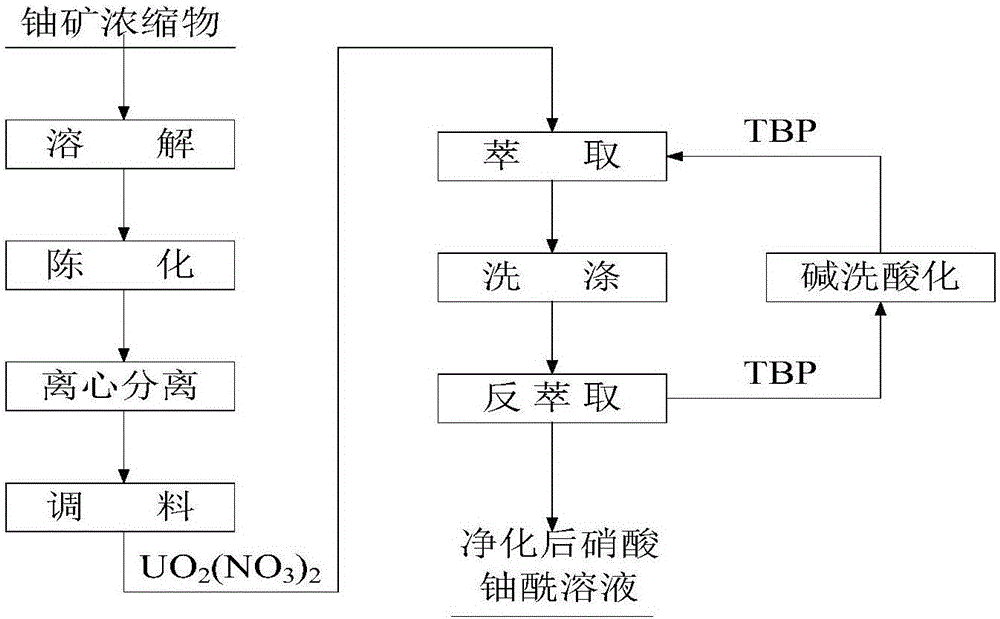

[0037] Through the analysis of the dissolution reaction principle of ammonium diuranate and U3O8, the main difference is that the dissolution of ammonium diuranate in nitric acid produces ammonium nitrate without the generation of gas, while the dissolution of U3O8 in nitric acid is accompanied by nitrogen oxides. The generation of gas, there will be no introduction of other impurities; this patent proposes such as figure 1 The following technical solutions are shown:

[0038] A method for purifying uranium of ammonium diuranate, comprising the following steps:

[0039] (1) dissolve

[0040] The material is ammonium diuranate with a uranium content of 70-75wt% mixed with uranium-containing substances;

[0041] Add the material into the nitric acid solution with an acidity of 5-10mol / L through a star feeder for dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com