Concentration method for nuclear-pure uranyl nitrate solution

A technology of uranyl nitrate and solution, applied in the field of uranium purification, can solve the problems of increased enterprise burden and high steam operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

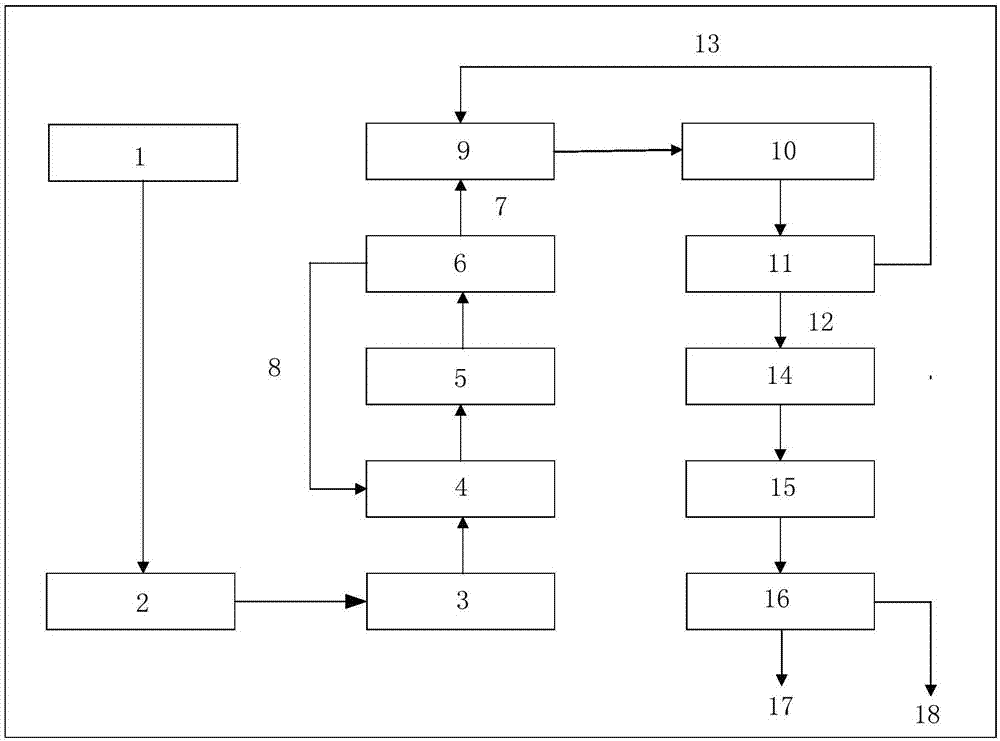

[0076] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0077] Such as figure 1 Shown, a kind of enrichment method for nuclear pure grade uranyl nitrate solution of the present invention comprises the following steps:

[0078] (1) Determine the system used in this method

[0079] The system used in the method includes a feed unit, a primary nanofiltration unit, a secondary nanofiltration unit, and a reverse osmosis unit;

[0080] 1. The feeding unit includes raw liquid tank, raw liquid pump and feeding tank;

[0081] After the uranyl nitrate solution is sampled and analyzed, it is poured into the stock solution tank, and a manual valve is set at the bottom of the stock solution tank;

[0082] When starting to concentrate, open the manual valve at the bottom of the stock solution tank, and the uranyl nitrate solution enters the feed tank through the stock soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com