Spacing track optimizing method of tool electrode for electrolytic machining of integral wheel

A technology for integral impellers and processing tools, which is applied in the direction of electrochemical processing equipment, manufacturing tools, metal processing equipment, etc., and can solve the problems of low processing efficiency, large processing allowance, and high processing cost of the channel between impeller blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

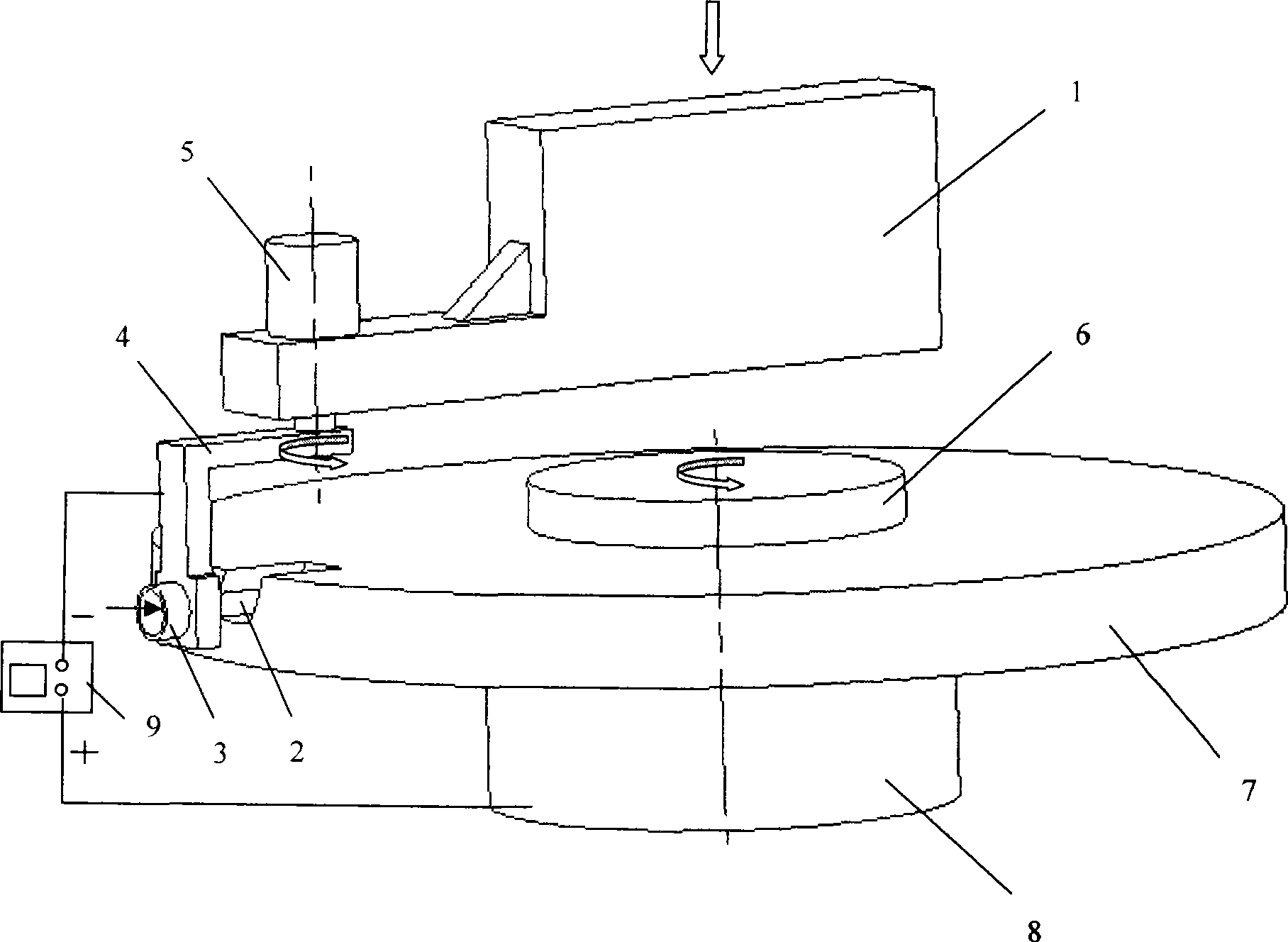

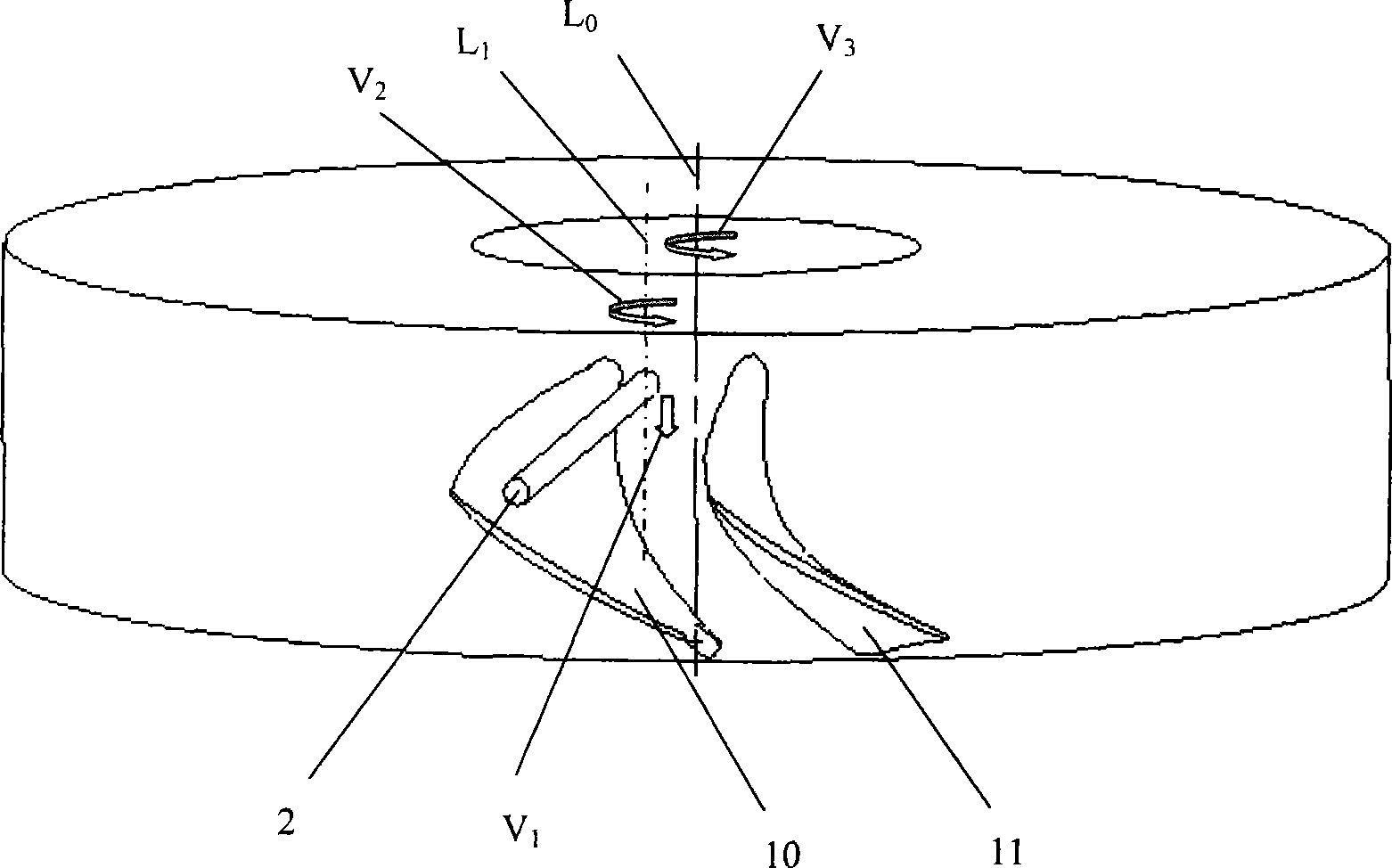

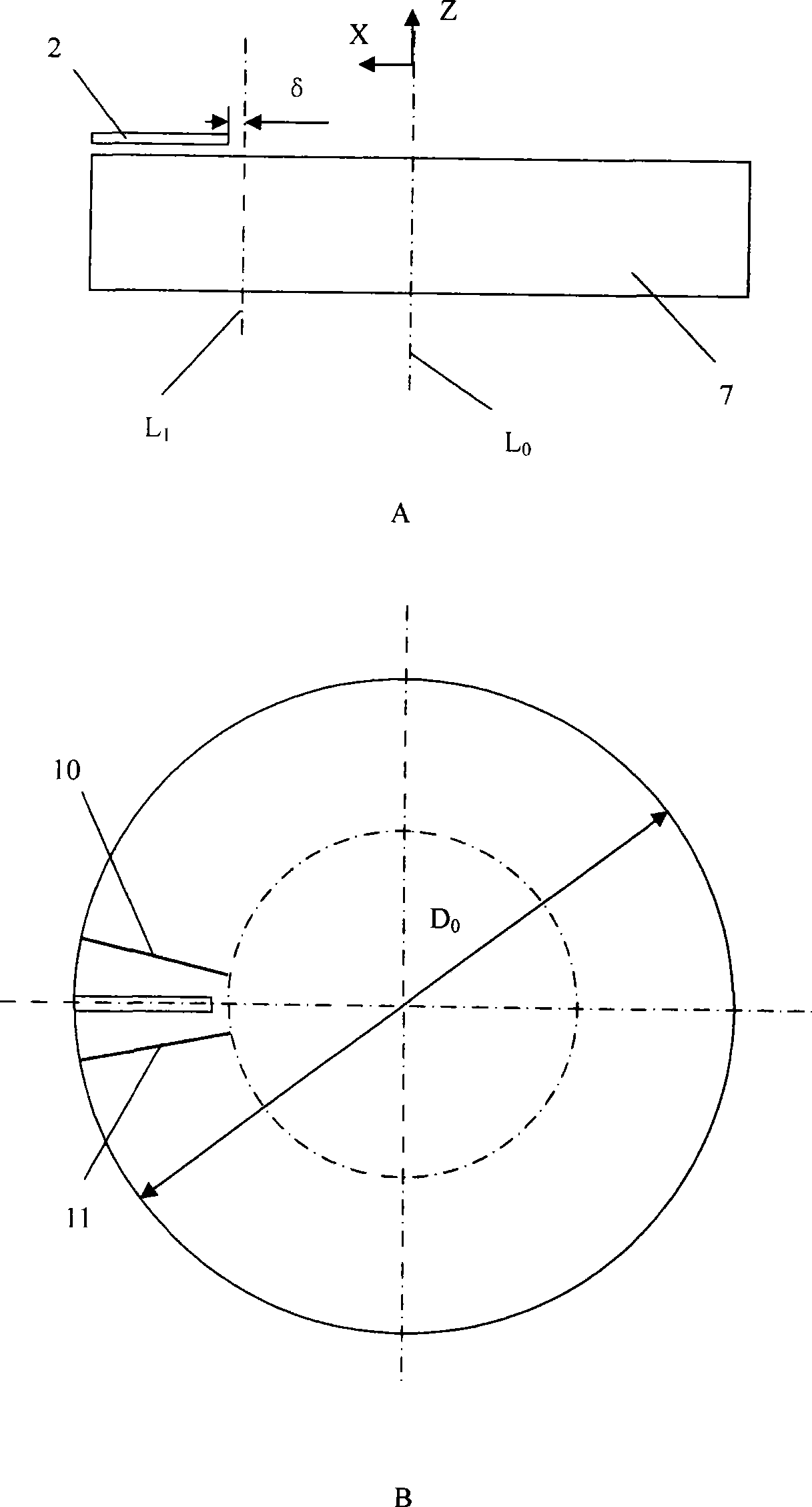

[0059] like figure 1 , 2 As shown, during processing, the integral impeller blank (anode) 7 is connected to the positive pole of the power supply 9, and the tool electrode (cathode) 2 is connected to the negative pole of the power supply 9. The tool cathode 2 moves along the straight line L under the control of the translation table 1 of the machine tool 0 at speed V 1 Linear feed, the cathode rotation transmission device 5 drives the tool cathode 2 around the straight line L 1 Rotation, so the tool cathode 2 realizes simultaneously along the line L 0 at speed V 1 Linear feed and around the straight line L 1 at angular velocity V 2 rotate. The impeller blank 7 at a certain angular velocity V 3 around its own axis L 0 Rotate, the tool cathode 2 and the impeller blank 7 are continuously fed, and keep a small gap (about 0.5mm). The temperature controller controls the heater to heat the electrolyte and maintain a constant temperature. The electrolyte enters the filter fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com