Processing method for assembling non-metal box transforming station case

A processing method and non-metallic technology, applied in the processing field of substation boxes, can solve the problems of high cost, complex processing of substation shells, and rigid shape, and achieve the effects of large plasticity, easy assembly and transportation, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

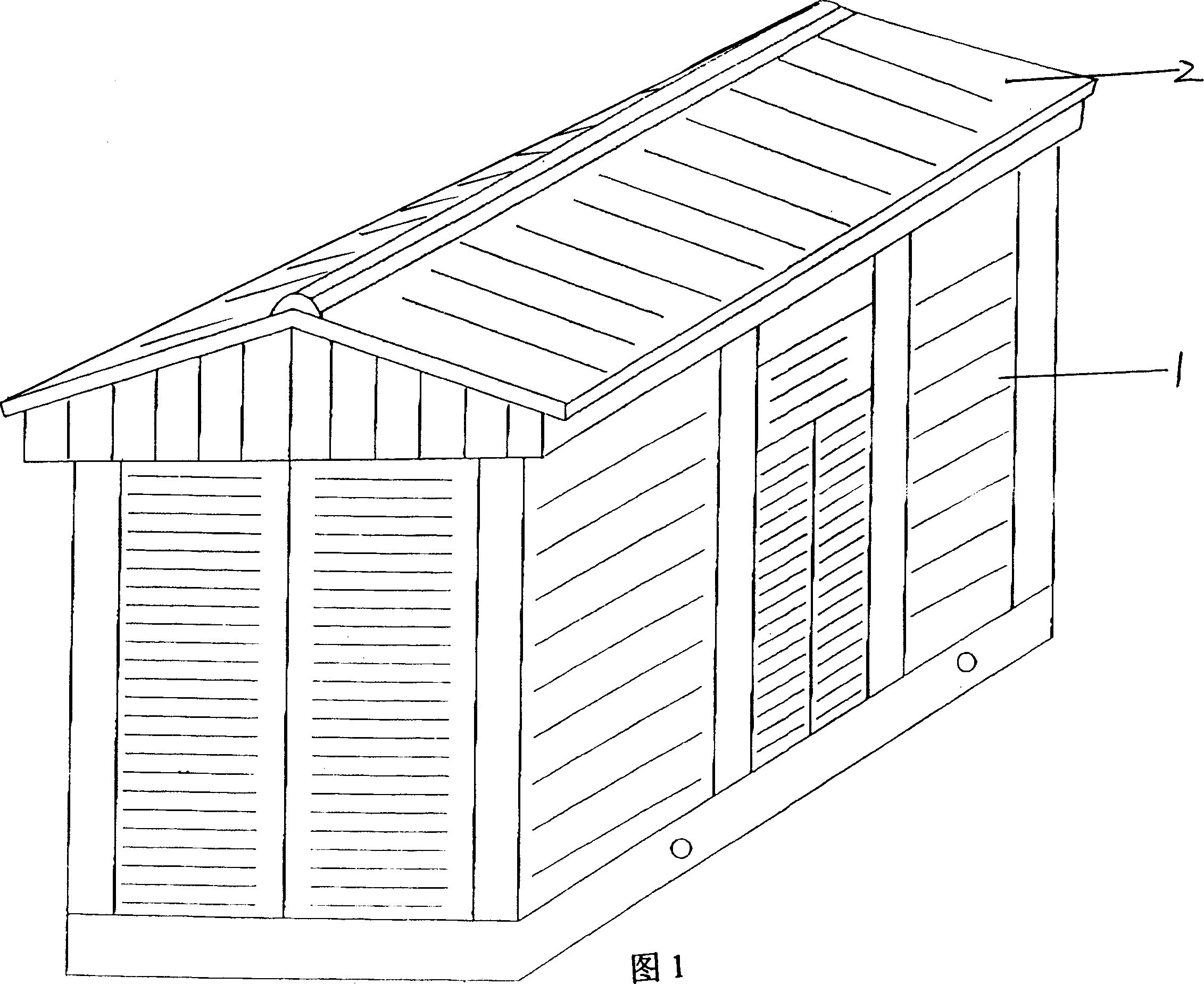

[0027] An assembled non-metal box substation shell, which is divided into two parts: the side wall 1 and the upper roof 2. The surface of the side wall 1 is in the shape of wooden slats, and the square columns of the side wall are in the form of tree poles with bark , the surface of the roof 2 is a plank shape. Its processing method is as follows:

[0028] FRP profiling art molds are selected, the inner surface of one mold is made into the shape of wooden slats, and the shape of tree poles with bark is made at the position of the square column, and the inner surface of the other mold is made into the shape of wooden slats , the inner surface of the FRP profiling art mold is coated with a release agent, and embedded components are placed in the film cavity;

[0029] First cast the surface layer slurry in the mold, and the surface layer slurry contains the following raw materials in parts by weight. In 1 part of cement, add 0.007 part of glass fiber, 1 part of sand, 0.32 part o...

Embodiment 2

[0034] An assembled non-metal box substation shell is divided into two parts: a side wall 1 and an upper roof 2. The surface layer of the side wall 1 is in the shape of stone, and the roof 2 is in the shape of tiles. Its processing method is as follows:

[0035] Choose the FRP imitation art mold, the inner surface of one mold is made into stone shape, the inner surface of the other mold is made into tile shape, the inner surface of the FRP imitation art mold is coated with release agent, and the pre-installed mold is placed in the film cavity buried components;

[0036] In the mold, the surface layer slurry is first cast, and the surface layer slurry contains the following raw materials in parts by weight. In 1 part of cement, add 0.008 parts of glass fiber, 1.2 parts of sand, 0.35 parts of water, and 0.03 parts of water that are compatible with it. Strengthening agent and 0.003 parts of composite water reducing agent;

[0037] Immediately afterwards, cast the main slurry in...

Embodiment 3

[0041] A prefabricated non-metal box substation shell is divided into two parts: a side wall 1 and an upper roof 2. The surface layer of the side wall 1 is in the shape of thick bamboo poles, and the roof 2 is in the shape of straw. Its processing method is as follows:

[0042] Choose glass fiber reinforced plastic imitation art mold, the inner surface of one mold is made into the shape of straw, and the inner surface of the other mold is made into the shape of thick bamboo rod, and the inner surface of the glass fiber reinforced plastic imitation art mold is coated with a release agent, and the film cavity Embedded components are placed inside;

[0043] In the mold, the surface slurry is first cast, and the surface slurry contains the following raw materials in parts by weight. In 1 part of cement, add 0.005 part of glass fiber, 0.9 part of sand, 0.3 part of water, and 0.02 part of water that are compatible with it. Strengthening agent and 0.001 parts of composite water redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com