Planar flexible room-temperature NO<2> sensor based on three-dimensional MXene folded ball/ZnO composite material and preparation method thereof

A composite material and sensor technology, used in material resistance, material analysis, material analysis by electromagnetic means, etc., can solve problems such as unfavorable gas sensing, aggregation, loss of large specific surface area, etc., and achieve large specific surface area and low operating temperature. , the effect of improving the sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

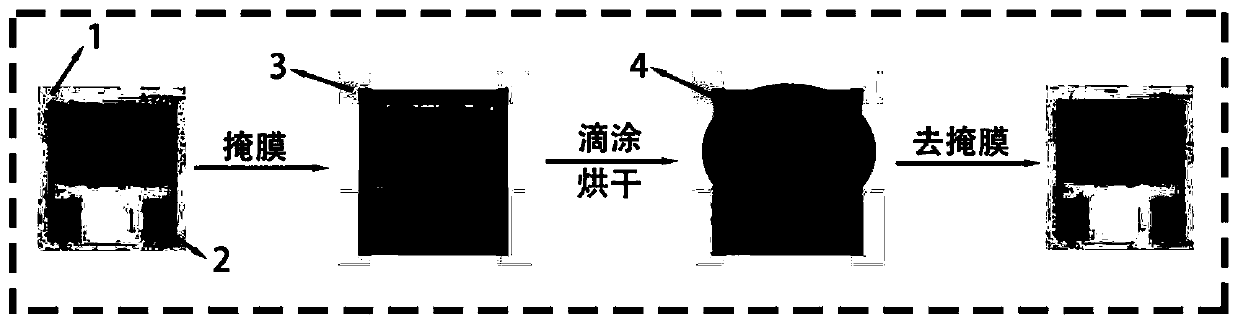

[0042] The three-dimensional MXene wrinkled ball / ZnO composite material is used as the sensitive electrode material to fabricate a planar flexible room temperature gas sensor. The fabrication process is as follows:

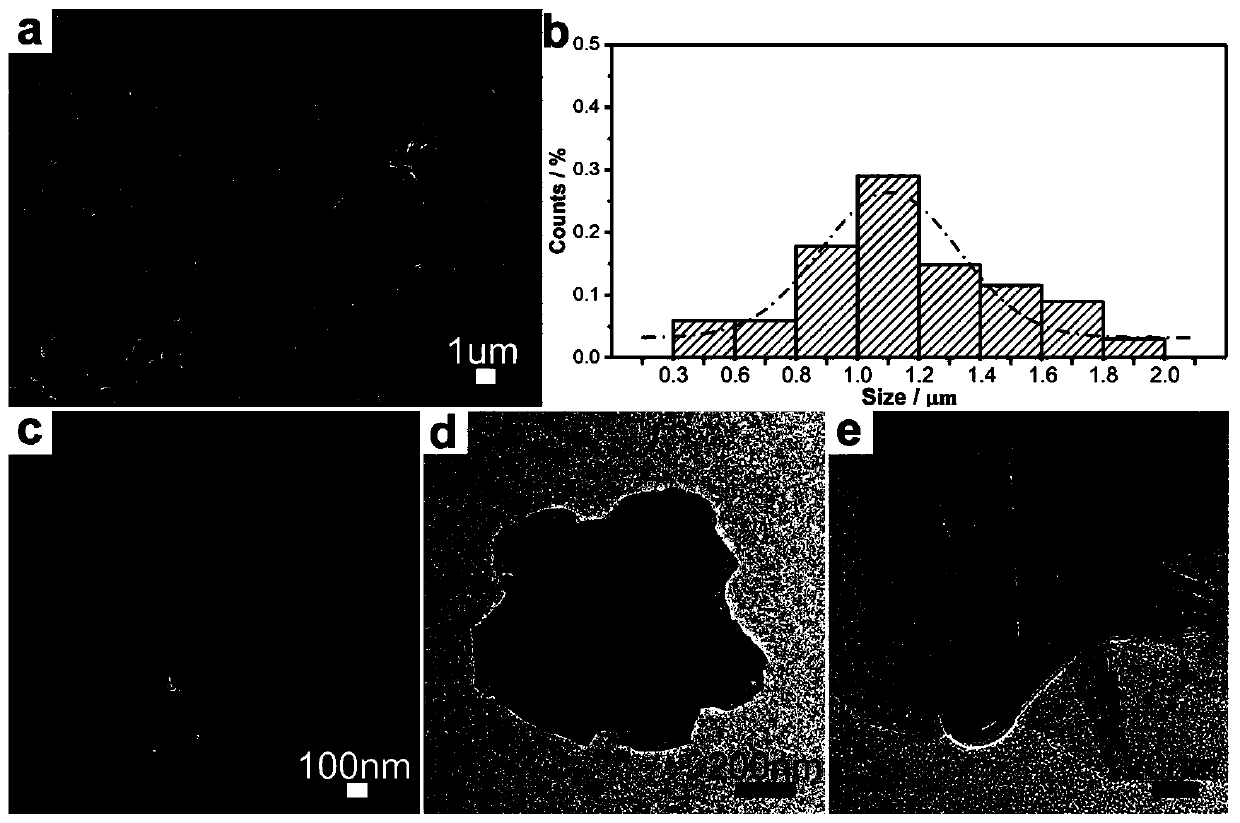

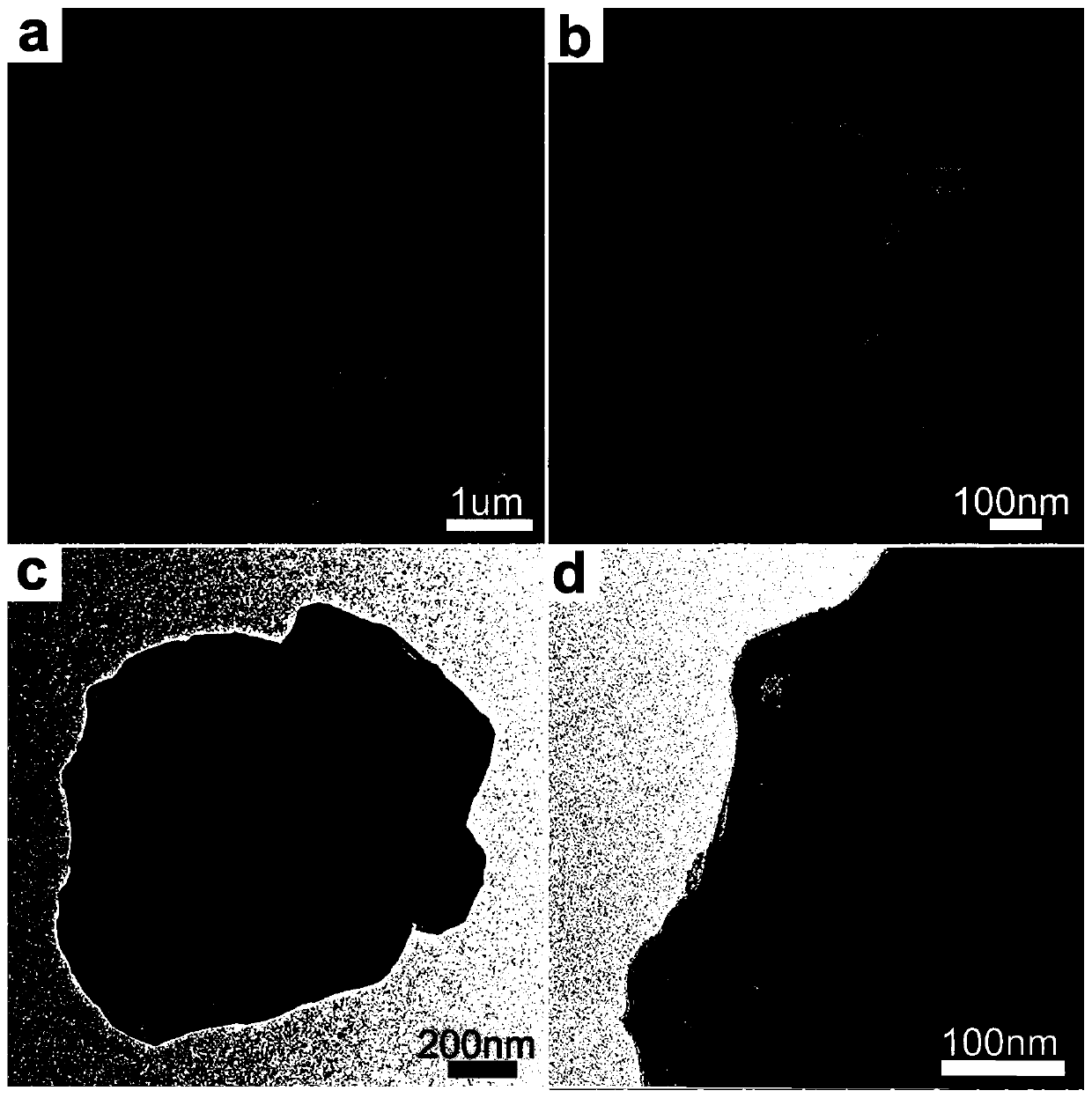

[0043] (1) Preparation of two-dimensional MXene material: weigh 1 gram of Ti 3 AlC 2 Slowly add 40mL of concentrated hydrochloric acid (36% by mass) and 1 gram of LiF into a 50mL PET bottle, stir and react in a water bath at 40°C for 24 hours, and the product after the reaction is washed and centrifuged repeatedly with deionized water until the supernatant The liquid pH is 6. Add the clay-like precipitate in the lower layer to 60 mL of deionized water, sonicate in an ice bath in a column ultrasonic machine for 1 hour, and finally centrifuge at a speed of 3000 rpm for 1 hour, take the upper layer liquid, and obtain the MXene dispersion. Measure 10mL of the MXene dispersion for suction filtration, place the MXene sheet obtained by suction filtration in a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com