Preparation and application of dry-mixed mortar for asphalt carbon fiber cement-based self-compaction concrete of slab ballastless track

A technology of slab ballastless track and pitch carbon fiber, which is applied in the field of building materials, can solve performance problems, achieve the effects of reducing surface energy, increasing elastic modulus, and increasing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

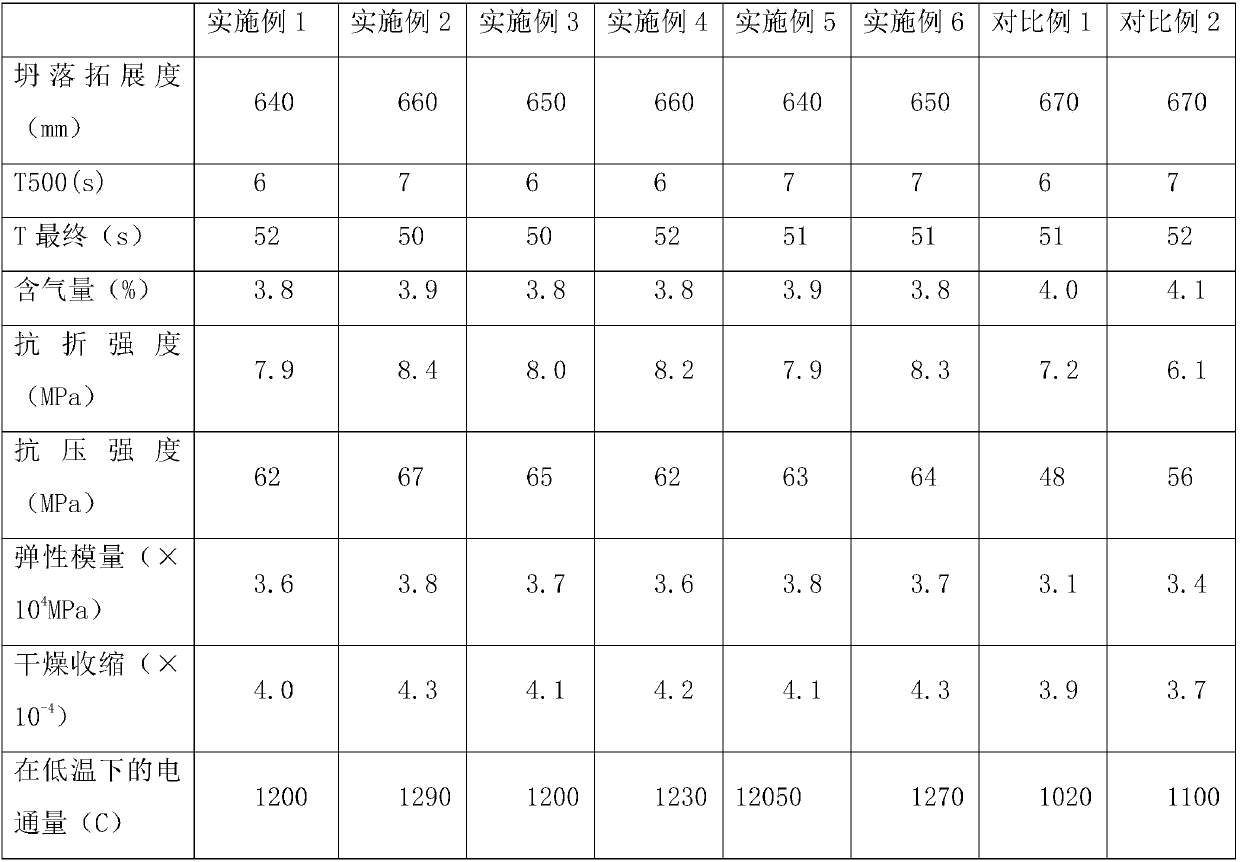

Examples

Embodiment 1

[0026] A kind of preparation of dry powder mortar for slab ballastless track asphalt carbon fiber cement-based self-compacting concrete comprises the following steps:

[0027] (1) Oxidize the pitch carbon fiber in the air at 360°C for 1h, then impregnate it in a toluene solution containing 0.5% epoxy resin for 30min, take it out, dry and solidify it at 100°C for 20min, and obtain a high degree of crystallite orientation Pretreated pitch carbon fiber with a carbon content of more than 90% and a carbon content higher than 99.8%.

[0028] (2) The rubber powder is further pulverized through a 100-mesh sieve, and then spread evenly. After being activated by low-temperature plasma for 1 min at a power of 300W, it is soaked in 0.2% aqueous solution of silane coupling agent KH-550 for 30 min. Dry and solidify for 20 minutes to obtain activated rubber powder.

[0029] (3) According to parts by weight, stir 0.5 parts of pitch carbon fiber and 1 part of active rubber powder to disperse ...

Embodiment 2

[0031] A kind of preparation of dry powder mortar for slab ballastless track asphalt carbon fiber cement-based self-compacting concrete comprises the following steps:

[0032](1) Oxidize the pitch carbon fiber in the air at 400°C for 2h, then immerse it in a toluene solution containing 1% epoxy resin for 60min, take it out, dry and solidify it at 110°C for 30min, and obtain a crystallite orientation degree higher than 90%, pretreated pitch carbon fiber with a carbon content higher than 99.8%.

[0033] (2) The rubber powder is further pulverized through a 150-mesh sieve, then spread evenly, and after being activated by low-temperature plasma for 3 minutes at a power of 500W, it is soaked with 0.5% silane coupling agent KH-550 aqueous solution for 30-60min, Dry and solidify at ℃ for 30 minutes to obtain activated rubber powder.

[0034] (3) According to parts by weight, stir 0.5 parts of pitch carbon fiber and 5 parts of active rubber powder to disperse the two evenly to form a...

Embodiment 3

[0036] A kind of preparation of dry powder mortar for slab ballastless track asphalt carbon fiber cement-based self-compacting concrete comprises the following steps:

[0037] (1) Oxidize the pitch carbon fiber in the air at 380°C for 1.5h, then impregnate it in a toluene solution containing 0.6% epoxy resin for 40min, take it out, dry and solidify it at 105°C for 25min, and obtain a high degree of crystallite orientation Pretreated pitch carbon fiber with a carbon content of more than 90% and a carbon content higher than 99.8%.

[0038] (2) The rubber powder is further pulverized through a 110-mesh sieve, and then spread evenly. After being activated by low-temperature plasma for 2 minutes at a power of 400W, it is impregnated with 0.3% silane coupling agent KH-550 aqueous solution for 45 minutes. Dry and solidify for 25 minutes to obtain activated rubber powder.

[0039] (3) According to parts by weight, stir 0.05 parts of pitch carbon fiber and 3 parts of active rubber pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com