Self-compacting concrete

A technology of self-compacting concrete and mixed sand, which is applied in the field of concrete, can solve the problems of large amount of cementitious materials and large shrinkage, and achieve the effects of improving volume stability, good cohesion, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

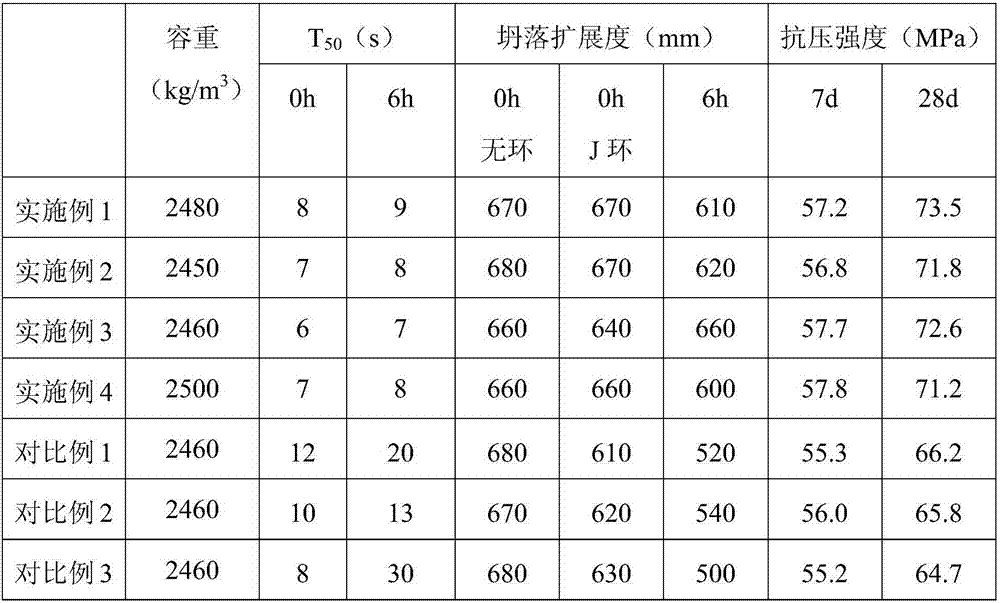

Examples

Embodiment 1

[0027] A self-compacting concrete, comprising the following components by weight: 400 parts of cement, 80 parts of fly ash, 50 parts of slag powder, 50 parts of calcium oxide expansion agent, 9 parts of silica fume, 800 parts of mixed sand, and 948 parts of gravel , 140 parts of drinking water, 3 parts of composition additives and a high-performance water reducing agent accounting for 1% of the mass fraction of the above-mentioned gelling material.

[0028] The above crushed stone is a mixture of large stones with a particle size of 10-16 mm and small stones with a particle size of 5-8 mm, and the weight ratio of the small stones to the large stones is 1:1.3. The cement is Portland cement with a strength grade of 42.5, and the fly ash is first-class fly ash. The mixed sand is mixed sand including medium sand, ultra-fine sand and machine-made sand, the fineness modulus of the mixed sand is 2.3, the mud content in the mixed sand is not more than 2wt%, and the stone powder conten...

Embodiment 2

[0031] A self-compacting concrete, comprising the following components by weight: 350 parts of cement, 60 parts of fly ash, 56 parts of slag powder, 62 parts of ettringite expansion agent, 12 parts of silica fume, 750 parts of mixed sand, and 1010 parts of crushed stone 150 parts, 150 parts of drinking water and a high-performance water reducing agent accounting for 2% of the mass fraction of the above-mentioned gelling material.

[0032] The crushed stone is a mixture of large stones with a particle size of 16-20 mm and small stones with a particle size of 8-10 mm, and the weight ratio of the small stones to the large stones is 1:1.5. The cement is Portland cement with a strength grade of 52.5, and the fly ash is first-grade fly ash. The mixed sand is mixed sand including medium sand, ultra-fine sand and machine-made sand, the fineness modulus of the mixed sand is 3.0, the mud content in the mixed sand is not more than 2wt%, and the stone powder content in the mixed sand is n...

Embodiment 3

[0035] A self-compacting concrete, including 360 parts of cement, 54 parts of fly ash, 52 parts of slag powder, 53 parts of expansion agent composed of calcium oxide and calcium sulfoaluminate in a weight ratio of 1:1, 11 parts of silica fume, mixed sand 748 parts, 1020 parts of gravel, 156 parts of drinking water, 6 parts of composition additives and a high-performance water reducing agent accounting for 1.5% of the mass fraction of the above-mentioned gelling material.

[0036]The crushed stone is a mixture of large stones with a particle size of 10-20 mm and small stones with a particle size of 5-10 mm, and the weight ratio of the small stones to the large stones is 1:1.4. The cement is Portland cement with a strength grade of 42.5, and the fly ash is first-class fly ash. The mixed sand is mixed sand including medium sand, ultra-fine sand and machine-made sand, the fineness modulus of the mixed sand is 2.5, the mud content in the mixed sand is not more than 2wt%, and the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com