Ladle permanent lining and manufacturing method thereof

A ladle and permanent technology, applied in the field of iron and steel metallurgical ladle lining refractory materials, can solve the problems of high cost of integral casting tire mold, long construction period, high tire mold cost, etc., to meet the heat insulation requirements and simplify the repair Technological process, the effect of improving safe use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

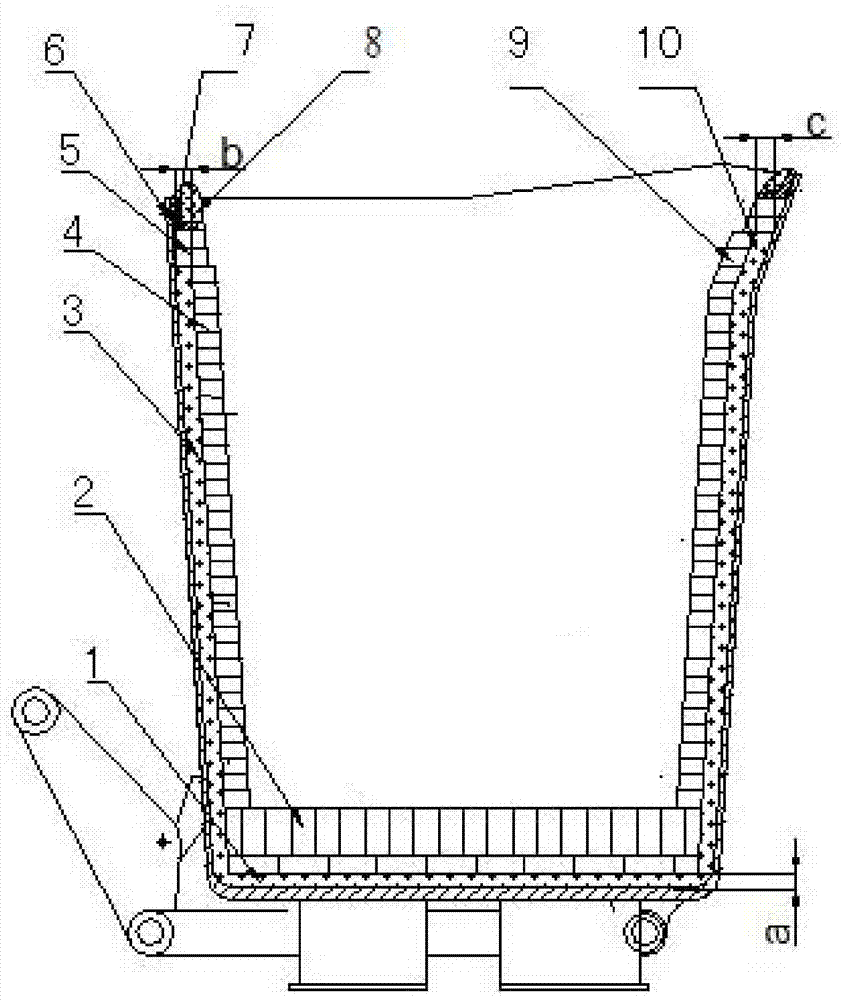

[0046] like figure 1 As shown, a permanent lining of a molten iron ladle is laid on the inner wall of the molten iron ladle shell 6, and sequentially includes a bottom permanent lining 1, a wall permanent lining 3 and a spout permanent lining 10 from bottom to top. It is prepared by the method of segmental pouring, does not use integral pouring tire mold, and is constructed synchronously with the brickwork lining.

[0047] The thickness b of the cladding wall permanent lining 3 is 90mm, and the loading capacity of the molten iron ladle is 135t, which meets the requirement of 130±5t for the loading capacity of the 120t re-blowing converter.

[0048] The thickness a of the bottom permanent lining castable 1 is 100mm.

[0049] The thickness c of the mouthpiece permanent lining (10) is 65mm.

[0050] The micro-expansion self-flowing castable used for the permanent lining of the bottom (1), the permanent lining of the wall (3) and the permanent lining of the mouth (10) is compose...

Embodiment 2

[0068] Others are the same as embodiment 1, the difference is:

[0069] The thickness b of the permanent lining 3 of the cladding wall is 65mm, and the loading capacity of the molten iron ladle is 145t, which meets the requirement of 140±5t for the loading capacity of the 150t re-blowing converter.

[0070] The thickness a of the bottom permanent lining castable 1 is 50mm.

[0071] The thickness c of the permanent liner 10 for wrapping the spout is 45-65 mm.

[0072] The micro-expansion self-flowing castable used for the permanent lining of the bottom (1), the permanent lining of the wall (3) and the permanent lining of the mouth (10) is composed of the following materials in percentage by weight: tertiary grade 8-5mm particle size High bauxite 10%, 3mm ≦ particle size 2 o 3 Micropowder 8.0%, silicon micropowder with particle size ≦0.047mm 6.0%, pure calcium aluminate cement 4.5%, sodium hexametaphosphate 0.05%, soft clay 0.45%, all are percentages by weight.

[0073] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com