Self-compacting concrete and preparation method thereof

A self-compacting concrete and methoxyl technology, which is applied in the field of mineral powder to prepare self-compacting concrete and large-volume fly ash, can solve the problems of environmental pollution, cement quality decline, poor workability of concrete, etc., and achieve environmental protection and environmental benefits. , the effect of environmental protection and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

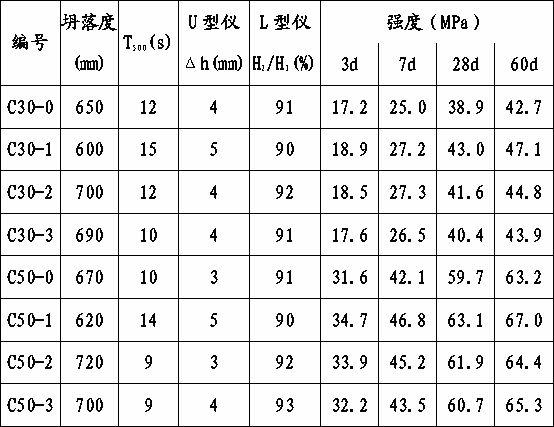

[0030] Take the two grades C30 and C50 commonly used in concrete as an example. The raw material is P.O42.5 cement with a specific surface area of 400kg / m 3 Left and right, stable quality and strength; Class II fly ash; S95 class mineral powder, specific surface area greater than 400kg / m 3 ; 80μm-5mm mine waste rock, fineness modulus greater than 2.6; 5-20mm mine waste rock, continuous gradation. See Table 1 for specific mix ratios and Table 2 for concrete performance comparison.

[0031] Table 1 Concrete mix ratio Unit: kg / m 3

[0032] Numbering power level cement fly ash mineral powder 5~20m mine waste rock 0~5mm mine waste rock water Low air-entraining polycarboxylate polyacrylamide C30-0 C30 250 80 90 990 850 168 9.02 0 C30-1 C30 200 80 105 990 850 158 4.06 4.06 C30-2 C30 200 80 105 990 850 155 6.09 2.02 C30-3 C30 220 80 105 990 850 160 6.96 1.16 C50-0 C50 400 70 90 1010 710 160 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com