Method for reinforcing round-section pier by using polyurethane concrete materials and thin-wall steel sleeves

A technology of polyurethane concrete and steel sleeves, applied in bridge reinforcement, bridges, bridge parts, etc., can solve the problems that the tensile and compressive strength of components cannot be improved at the same time, the interface strength is insufficient, and the construction period is long, etc., and the reinforcement effect is obvious , short curing time and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

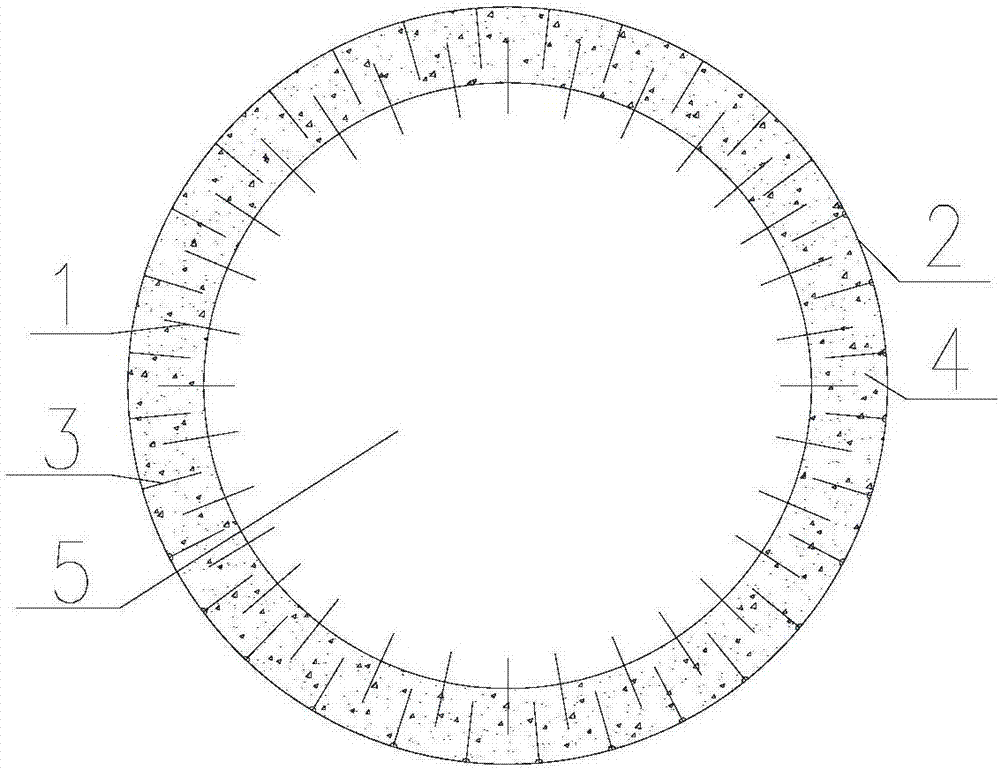

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment in detail, a kind of method that utilizes polyurethane concrete material and thin-walled steel sleeve to reinforce circular cross-section bridge pier described in this embodiment is carried out according to the following steps:

[0016] 1. Chisel away the mortar layer on the concrete surface of the reinforced part of the concrete pier until the concrete coarse aggregate is exposed, clean the surface of the concrete pier, and dry the reinforced part of the concrete pier;

[0017] 2. Implant the connecting steel bar in the reinforced part of the concrete pier, take two semicircular thin-walled steel sleeves, and then arrange the welding shear nails in a plum blossom shape inside the semicircular thin-walled steel sleeves to obtain the semicircular thin-walled steel with welded shear nails Sleeve; the distance between the welded shear studs of the semicircular thin-walled steel sleeve is 1 / 5 to 1 / 3...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, when the concrete at the reinforced part of the concrete pier is broken, the broken concrete should be cleaned until only the complete concrete connected with the main body remains; when the reinforced part of the concrete pier When there are cracks smaller than 0.2mm, seal the cracks; when there are cracks of 0.2mm to 2mm in the reinforced part of the concrete pier, fill the cracks; when there are cracks larger than 2mm in the reinforced part of the concrete pier, follow the direction of the crack At equal intervals of 20cm, drill holes with a diameter of not less than 8mm toward the direction of the crack. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the connecting steel bar described in step 2 is a common steel bar or a bolted anchor bar. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com