High-perturbance underwater masonry mortar

A masonry mortar and anti-disturbance technology, which is applied in the field of high-disturbance underwater masonry mortar, can solve the problems of easy separation of sand and gravel, easy loss of cement, and influence on hardening, and achieve the effect of high normal hardening, good construction and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

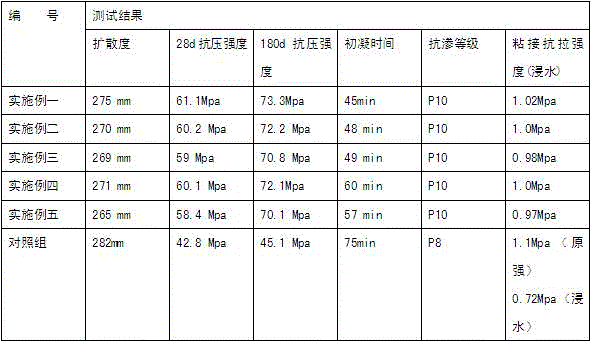

Examples

Embodiment 1

[0025] The components contained in the high-disturbance underwater masonry mortar and the mass fractions of each component are: 50 parts of special rapid hardening cement; 220 parts of ordinary cement; 15 parts of resin rubber powder; 680 parts of natural medium sand; 35 parts of anti-disturbance admixture ; 45 parts of water-based epoxy resin; wherein, the components contained in the anti-disturbance admixture and the mass parts of each component are: 3 parts of silicon powder; 3 parts of hydroxypropyl methylcellulose; superplasticizer 0.8 parts; 6 parts of thixotropic agent; 6 parts of special rapid hardening cement; 12 parts of flocculant; 6 parts of early strength agent.

Embodiment 2

[0027] The components contained in the high-disturbance underwater masonry mortar and the mass fractions of each component are: 50 parts of special rapid hardening cement; 220 parts of ordinary cement; 15 parts of resin rubber powder; 680 parts of natural medium sand; 40 parts; 40-50 parts of water-based epoxy resin; wherein, the components contained in the anti-disturbance admixture and the mass parts of each component are: 1 part of silicon powder; 2 parts of hydroxypropyl methylcellulose; 0.5 parts of superplasticizer; 7 parts of thixotropic agent; 5 parts of special rapid hardening cement; 15 parts of flocculant; 5 parts of early strength agent.

Embodiment 3

[0029] As a preferred formula of the present invention, the components and the mass fraction of each component are: 50 parts of special rapid hardening cement; 220 parts of ordinary cement; 15 parts of resin rubber powder; 675 parts of natural medium sand; 40 parts; 40-45 parts of water-based epoxy resin; wherein, the components contained in the anti-disturbance admixture and the mass parts of each component are: 5 parts of silicon powder; 3 parts of hydroxypropyl methylcellulose; 0.8 parts of superplasticizer; 6 parts of thixotropic agent; 8 parts of special rapid hardening cement; 14 parts of flocculant; 6 parts of early strength agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com