Unbalanced weight monitoring device and construction method for overall process of construction of hanging basket at upper part of horizontal rotation T structure

A monitoring device and a whole-process technology, applied in the testing of machine/structural components, measuring devices, static/dynamic balance testing, etc., can solve the problem of affecting the safety of the spherical hinge structure system, increasing the monitoring cost and workload, and achieving little effect, etc. problems, to achieve the effect of avoiding discreteness, ensuring data, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0025] see Figure 4 , used as an unbalanced weight monitoring device during the whole construction process of the hanging basket on the upper part of the horizontal rotation T structure.

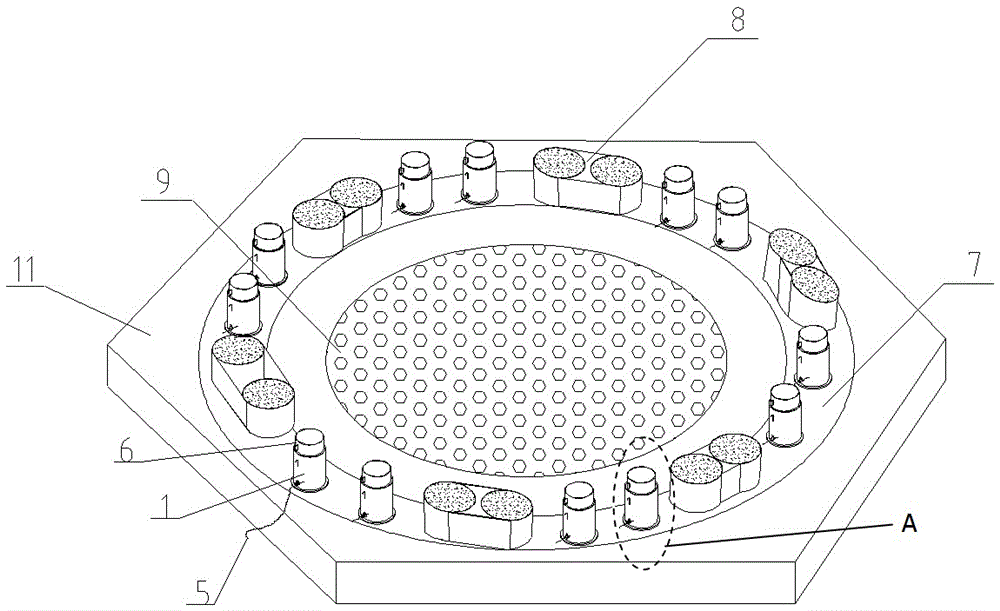

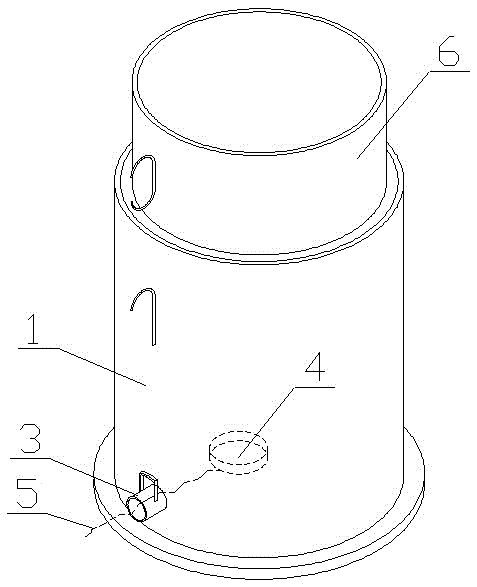

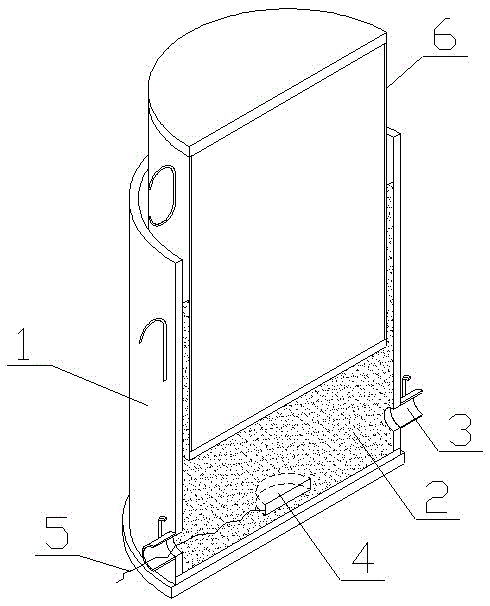

[0026] The hanging basket on the upper part of the T structure includes a slideway 7, a support foot 8, a spherical hinge 9, a concrete upper platform 10, and a concrete lower platform 11. The top of the concrete lower platform 11 is provided with a slideway 7, and the top of the concrete lower platform 11 inside the slideway 7 is provided with a ball joint 9. Support feet 8 are evenly distributed on the slideway 7 . A concrete upper platform 10 is provided on the top of the support foot 8 and the spherical hinge 9, such as figure 1 and Figure 4 shown. Including sand box outer sleeve 1, dry sand layer 2, pressure box 4, pressure box wire 5, sand box inner sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com