Preparation method of phosphono-group-containing water reducing agent

A phosphoric acid-based, superplasticizer technology, applied in the field of polycarboxylate superplasticizer preparation, can solve problems such as unstable product performance, and achieve the effect of improving steric hindrance effect and high adsorption density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Preparation of aminated polyether with a molecular weight of 354.

[0082] Chlorinated polyether preparation:

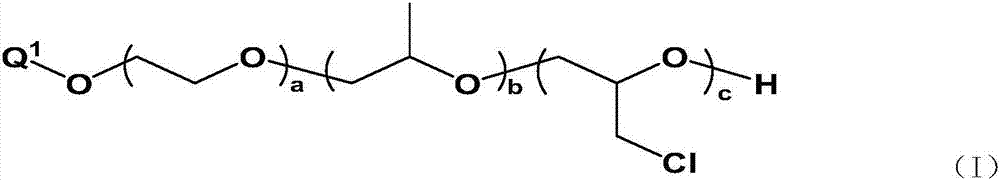

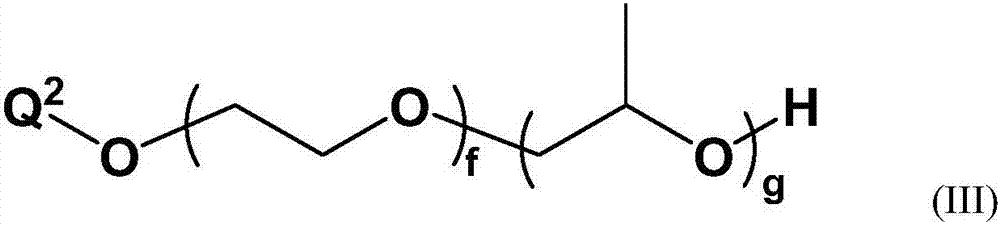

[0083] Initiator allyl alcohol, catalyst DMC. Weigh 100 parts of allyl alcohol and 1 part of catalyst DMC, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 100° C., and 20 parts of propylene oxide was passed into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. When the pressure in the reactor no longer decreases, feed 338 parts of ethylene oxide into the reactor; when the pressure in the reactor no longer decreases, continue to feed 159 parts of epichlorohydrin into the reactor, and maintain the reactor during the feeding process. The temperature is between 110-130°C and the pressure is between 0.2-0.4MPa. After the feeding of epichlorohydrin is comp...

Embodiment 2

[0095] Preparation of aminated polyether with a molecular weight of 962.

[0096] Chlorinated polyether preparation:

[0097] Initiator 3-methyl-3-buten-1-ol, catalyst DMC. Weigh 100 parts of 3-methyl-3-buten-1-ol and 1.2 parts of catalyst DMC, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 100° C., and 20 parts of propylene oxide was passed into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 30 parts of propylene oxide, until the pressure of the reactor is no longer reduced, feed 782 parts of ethylene oxide into the reactor; 215 parts. During the feeding process, keep the temperature of the reactor between 110-130°C and the pressure between 0.2-0.4MPa. After the feeding of epichlorohydrin is completed, keep the temperature at 120°C for about 1h. ...

Embodiment 3

[0105] Phosphitylation of aminated polyethers.

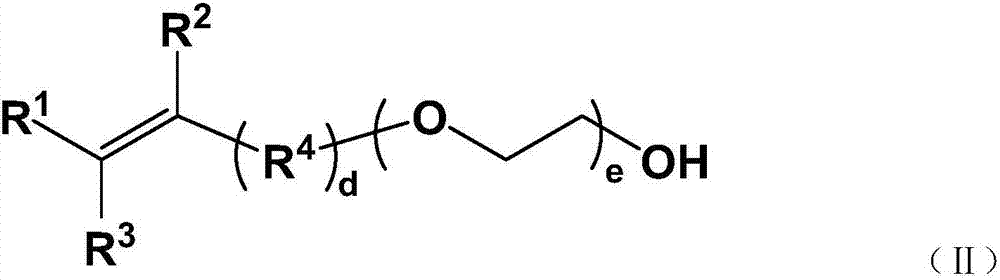

[0106] Weigh 300 parts of aminated polyether M1 and add it into the reaction kettle. Under the cooling condition of circulating water, add 251 parts of acidic reagent 37% concentrated hydrochloric acid and 100 parts of reaction solvent water, then raise the temperature to 80°C, and add 210 parts of phosphorous acid . Weigh 206 parts of 37% formaldehyde aqueous solution and add them all into the reaction kettle within 30 minutes. Continue to fully stir at this temperature for 30 minutes, then raise the temperature to 100° C., the pressure in the reactor is 0.1 MPa, and the reaction time is 10 hours. After the reaction, the water and insoluble salts in the reaction system were removed by vacuum filtration and rectification device to obtain light brown unsaturated polyether monomer containing phosphorous acid group, denoted as N1(Q 1 OH=allyl alcohol, a:b=22:1, c=1, ethylenediamine is the aminating reagent). Tested by GPC, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com