Multi-branched polycarboxylic water reducer with excellent function of slump protection and preparation method thereof

A technology of branched polycarboxylic acid and superplasticizer, which is applied in the field of multi-branched polycarboxylate superplasticizer and its preparation, which can solve the problem of poor water solubility of crosslinking agent, affecting the state of superplasticizer, and unsatisfactory crosslinking effect, etc. problems, achieve the effects of improved freeze-thaw resistance, far-reaching environmental protection, and improvement of cement sensitivity and unsuitable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Monomer a 128.8g

[0043] (Maleic anhydride methoxypolyethylene glycol ether diester, the number of EO added is n=13)

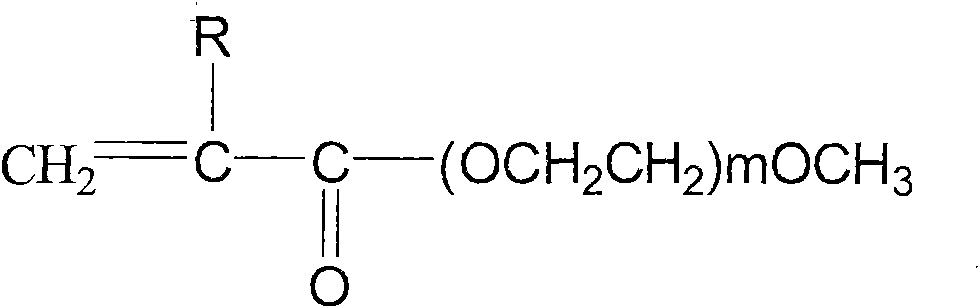

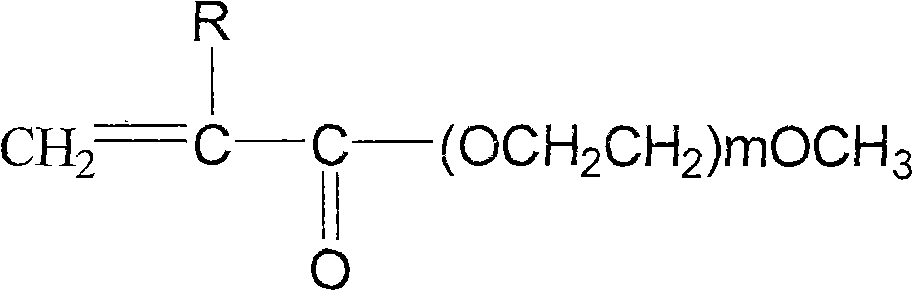

[0044] Monomer b 106.7g

[0045] (methoxypolyethylene glycol methacrylate, the number of added EO is m=28)

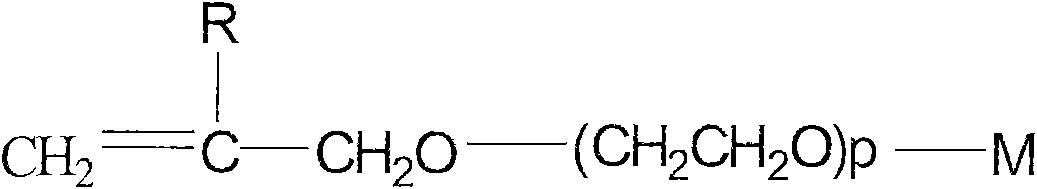

[0046] Monomer c 67.9g

[0047] (Propyl alcohol polyoxyethylene ether maleic anhydride ester, the number of EO added is p=28)

[0048] Monomer d 19.6g

[0049] (maleic anhydride)

[0050] Put 268g of water and monomer a into a four-necked reaction flask, purged with nitrogen, heated to 70°C with an oil bath, and added dropwise the aqueous solution composed of monomer b, monomer c, monomer d and 48.5g of water and 130 g of 5% ammonium persulfate in water. Use a certain period of time to evenly add the initiator, wherein the initiator is added later than the aqueous solution of the polymerizable monomer. After the dropwise addition, keep warm for 2 hours, lower the temperature to 30° C., adjust the pH value of the reactant to 6.0-6.5 with 4...

Embodiment 2

[0052] Monomer a 128.8g

[0053] (Maleic anhydride methoxypolyethylene glycol ether diester, the number of EO added is n=13)

[0054] Monomer b 127.4g

[0055] (methoxypolyethylene glycol methacrylate, the number of added EO is m=46)

[0056] Monomer c 65.3g

[0057] (Propyl alcohol polyoxyethylene ether maleic anhydride ester, the number of EO added is p=46)

[0058] Monomer d 21.6g

[0059] (maleic anhydride)

[0060] Put 270g of water and monomer a into a four-necked reaction flask, purged with nitrogen, heated to 70°C with an oil bath, and added dropwise the aqueous solution composed of monomer b, monomer c, monomer d and 53.6g of water and 150g of 5% sodium persulfate aqueous solution. Use a certain period of time to evenly add the initiator, wherein the initiator is added later than the aqueous solution of the polymerizable monomer. After the dropwise addition, keep the temperature for 2 hours, lower the temperature to 100%, adjust the pH value of the reactant to ...

Embodiment 3

[0062] Monomer a 128.8g

[0063] (Maleic anhydride methoxypolyethylene glycol ether diester, the number of EO added is n=13)

[0064] Monomer b 130.0g

[0065] (methoxypolyethylene glycol acrylate, the number of added EO is m=35)

[0066] Monomer c 55.4

[0067] (Propyl alcohol polyoxyethylene ether maleic anhydride ester, the number of EO added is p=28)

[0068] Monomer d 21.6g

[0069] (acrylic acid)

[0070] Put 269g of water and monomer a into a four-necked reaction flask, purged with nitrogen, heated to 35°C with an oil bath, and added 27.5% H 2 o 2 3.6g, the aqueous solution composed of monomer b, monomer c, monomer d and 69g water and 125g 3% formaldehyde and sodium bisulfite aqueous solution were added dropwise. Use a certain period of time to evenly add the initiator, wherein the initiator is added later than the aqueous solution of the polymerizable monomer. After the dropwise addition, keep the temperature for 2 hours, lower the temperature to 100%, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com