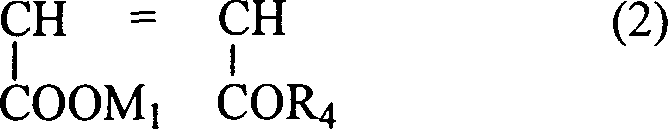

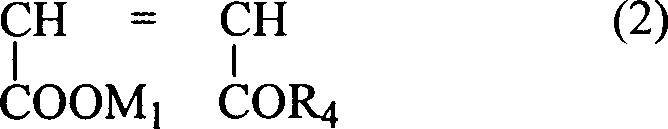

Polycarboxylic acid cement dispersant and its prepn process

A technology of cement dispersant and polycarboxylate, which is applied in the field of polycarboxylate cement dispersant and its preparation, can solve the problems of insufficient water-reducing performance of water-reducing agents, and achieve excellent slump retention, low energy consumption, high water-reducing The effect of water rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 120g of AE-1, 120g of deionized water, and 3.0g of 27.5% hydrogen peroxide into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 50°C. Simultaneously drop and mix the monomer aqueous solution of 14.7g maleic anhydride, 7.1g hydroxypropyl methacrylate, 50.0g deionized water and 20g 10% sodium formaldehyde sulfoxylate solution, and the dropping time is controlled at about 90 minutes , the reaction temperature is controlled at 48-52°C. After the dropwise addition, keep the temperature at 48-52° C. for about 30 minutes to make the polymerization complete. After the heat preservation is over, add 36 g of 30% NaOH to neutralize the pH to about 6.5 to obtain the polycarboxylate cement dispersant PC-1 of the present invention.

Embodiment 2

[0030] Add 120g of AE-2, 120g of deionized water, and 2.0g of 27.5% hydrogen peroxide into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 50°C. Add dropwise the monomer aqueous solution that has mixed 9.8g maleic anhydride, 50.0g deionized water and 4.4g methyl acrylate and 15g 10% sodium formaldehyde sulfoxylate aqueous solution, the time of dropping is controlled at about 90 minutes, and reaction temperature Control at 48-52°C. After the dropwise addition, keep the temperature at 48-52°C for about 30 minutes to complete the polymerization reaction. After the heat preservation is over, add 27.0g of 30% NaOH to neutralize the pH to about 6.5 to obtain the polycarboxylate cement dispersant PC-2 of the present invention. .

Embodiment 3

[0032] Add 120g of AE-3, 120g of deionized water, and 3.0g of 27.5% hydrogen peroxide into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 50°C. Simultaneously drop and mix the monomer aqueous solution of 14.7g maleic anhydride, 7.1g acrylamide, 50.0g deionized water and 4.4g methyl acrylate and 20g 10% sodium formaldehyde sulfoxylate solution, the time of dropping is controlled at 90 Minutes or so, the reaction temperature is controlled at 48-52°C. After the dropwise addition, keep the temperature at 48-52° C. for about 30 minutes to make the polymerization complete. After the heat preservation is over, add 36 g of 30% NaOH to neutralize the pH to about 6.5 to obtain the polycarboxylate cement dispersant PC-3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com