Method for preparing butyl rubber polymer

A butyl rubber and polymer technology, applied in the field of a butyl rubber polymer preparation method, can solve the problems of difficult catalyst dispersion, complicated preparation process, high refrigeration cost, etc., and achieve improved stability and initiation efficiency , simple method, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

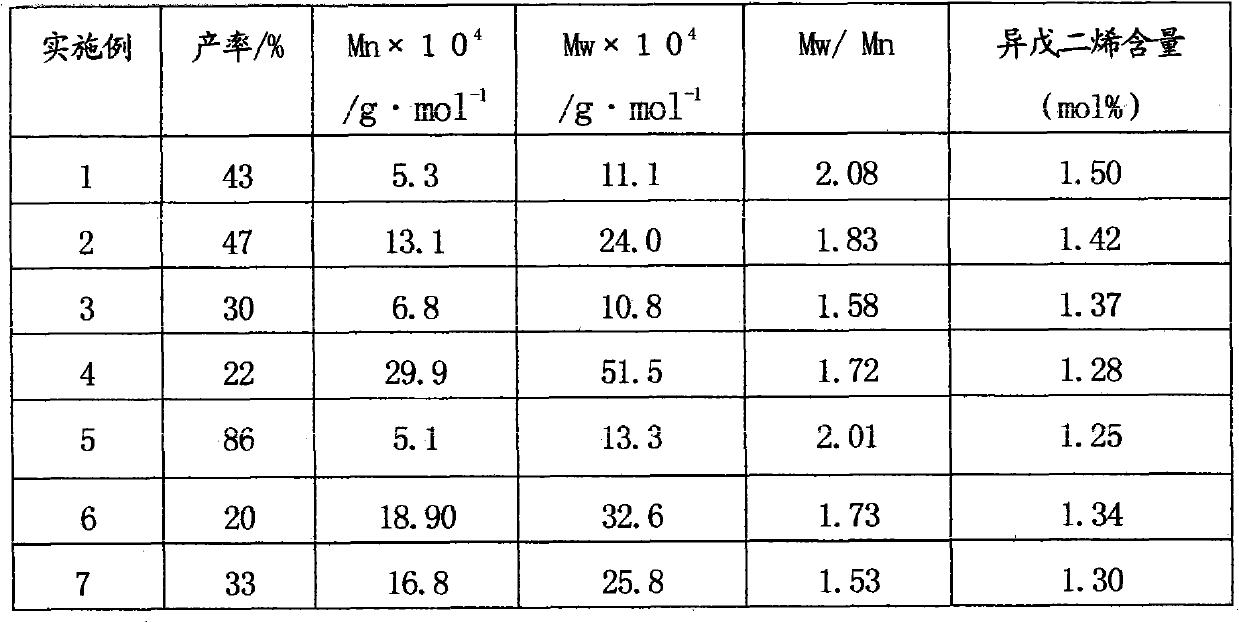

Examples

Embodiment 1

[0025] Add 48.6 μl of deionized water into 13.9ml of hexane solvent and mix evenly, then add 2.7ml of methyl aluminum dichloride at a temperature of 25°C to make a mixed catalyst with a concentration of 0.16mol / l, keep it warm for later use, Mix 60ml of methyl chloride and 240ml of hexane to make a mixed solvent, mix 70g of isobutene and 30g of isoprene under anhydrous and oxygen-free conditions to make a mixed raw material, then add the above mixed solvent to the above mixed raw material, Cool to -70°C and then add 16.6ml of mixed catalyst, continue to carry out the polymerization reaction at -70°C under anhydrous and oxygen-free conditions to generate butyl rubber polymer, wash the polymer with methanol, and dry it in a vacuum oven at 45 °C evaporated to constant weight to obtain butyl rubber polymer product.

Embodiment 2

[0027] Add 52.2 μl of deionized water into 8.7ml of hexane solvent and mix evenly, then add 2.2ml of ethyl aluminum dichloride at a temperature of 0°C to make a mixed catalyst with a concentration of 0.18mol / l, keep it warm for later use, Mix 90ml of methyl chloride and 210ml of hexane to make a mixed solvent. Under anhydrous and oxygen-free conditions, mix 80g of 2-methyl-1-butene and 20g of butadiene to make a mixed raw material, and then mix the above Add the solvent to the above mixed raw material, cool to -75°C and then add 10.9ml of mixed catalyst, continue to carry out polymerization reaction at -75°C under anhydrous and oxygen-free conditions to form butyl rubber polymer, wash the polymer with methanol , evaporated to constant weight at 45°C in a vacuum oven to obtain a butyl rubber polymer product.

Embodiment 3

[0029] Add 8.6 μlg of deionized water into 4.0ml of hexane solvent and mix evenly, then add 0.4ml of ethylaluminum dichloride at -20°C to make a mixed catalyst with a concentration of 0.08mol / l, and keep it warm for later use , mix 30ml of methyl chloride with 270ml of hexane to make a mixed solvent, and mix 45g of isobutene and 45g of 2-methyl-1-butene with 5g of isoprene and 5g of butadiene under anhydrous and oxygen-free conditions , to make a mixed raw material, then add the above mixed solvent to the above mixed raw material, cool to -80°C and then add 4.4ml of mixed catalyst, continue to carry out polymerization reaction at -80°C under anhydrous and oxygen-free conditions to form butyl For rubber polymer, the polymer was washed with methanol, and evaporated to constant weight in a vacuum oven at 45°C to obtain a butyl rubber polymer product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com