Soft segment cross-linked thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of thermoplastic polyurethane elastomers, can solve the problems that the proportion of small molecular alcohols is not easy to be accurately controlled, the influence of plasticization processing of polyurethane elastomers, and the continuity and stability are not easy to ensure. Excellent dimensional stability, stable and controllable melt viscosity, good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

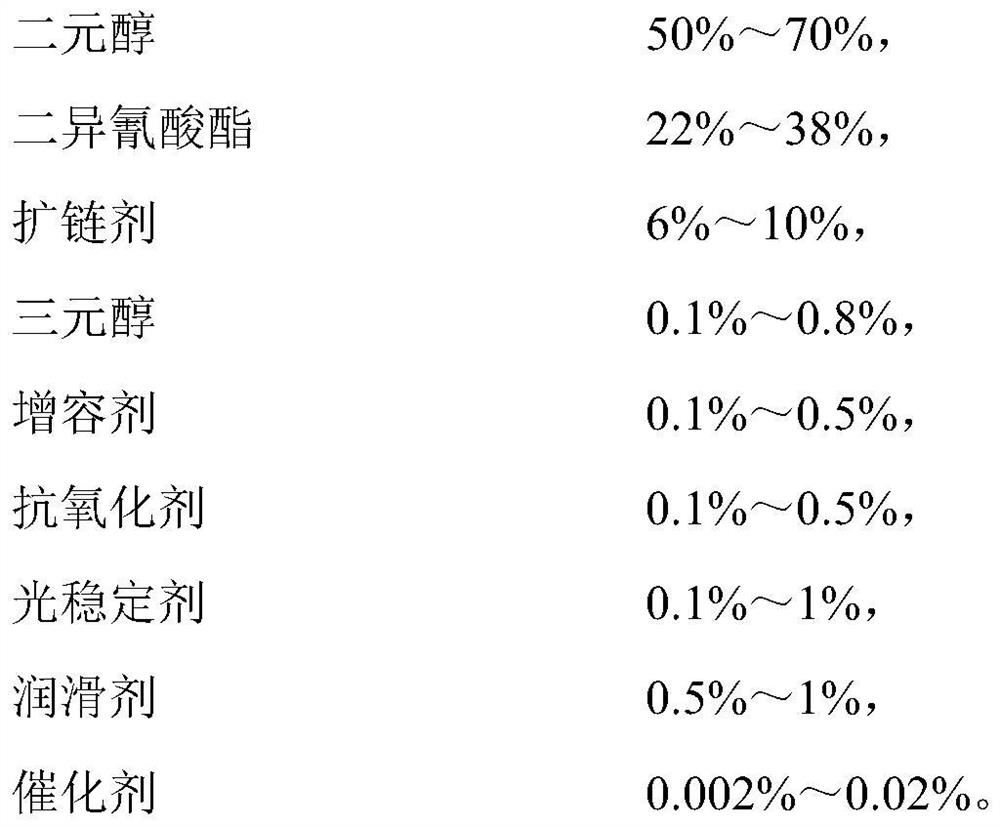

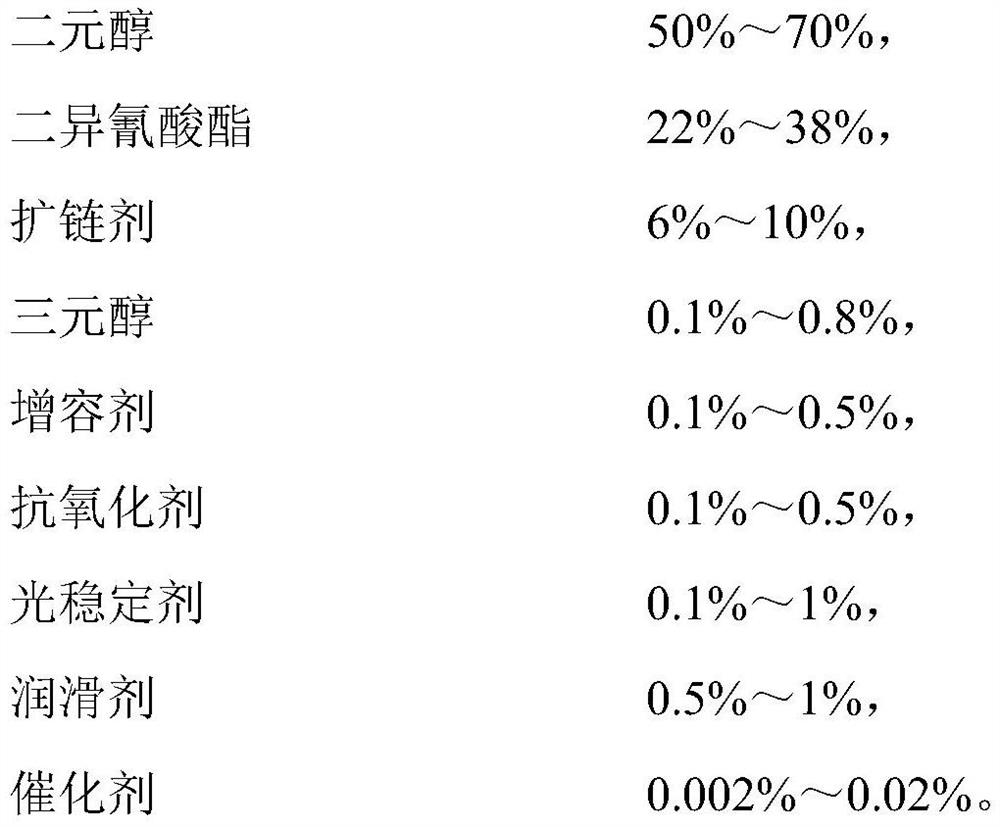

[0032] The thermoplastic polyurethane elastomer of described soft segment cross-linking, is made of the raw material of following percentage by weight:

[0033]

[0034]

[0035] The polybutylene adipate diol number average molecular weight is 3000.

[0036] Preparation process: Mix and heat diol, triol and compatibilizer to 110±5°C, mix well; heat diisocyanate to 70±5°C; heat chain extender to 65±5°C; heat the heated All raw material components are injected into the twin-screw reactor through precise metering and mixing, and antioxidants, light stabilizers, lubricants and catalysts are injected into the twin-screw reactor through an external addition device. The product is obtained after pelleting.

Embodiment 2

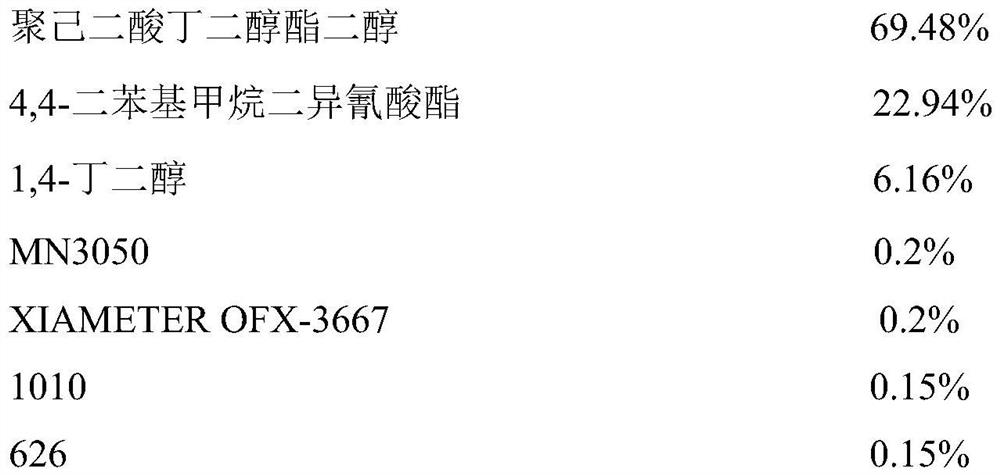

[0038] The thermoplastic polyurethane elastomer of described soft segment cross-linking, is made of the raw material of following percentage by weight:

[0039]

[0040] The polybutylene adipate diol number average molecular weight is 2000.

[0041] The preparation process is the same as in Example 1.

Embodiment 3

[0043] A soft segment cross-linked thermoplastic polyurethane elastomer is made of the following raw materials in weight percentage:

[0044]

[0045]

[0046] The polybutylene adipate diol number average molecular weight is 2000.

[0047] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com