Prefabricated asphalt block and asphalt layer formula

A prefabricated block and prefabricated technology, which is applied to pavement, roads, building components and other directions paved with prefabricated blocks, can solve the problems of reduced weather resistance of asphalt pavement and high temperature sensitivity of asphalt, and achieve water resistance and heat resistance enhancement , softening point and penetration, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

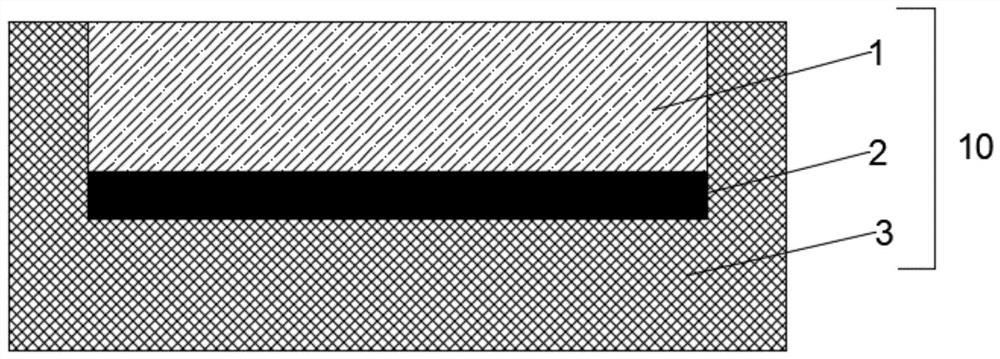

[0039] Such as figure 1 , an assembled asphalt prefabricated block 10, including a bottom plate 3, an adhesive layer 2 and an asphalt layer 1 from bottom to top; the shape of the asphalt prefabricated block 10 is a cuboid, the bottom plate 3 is a groove structure with an upper end opening, the adhesive layer 2 and The asphalt layers 1 are all set in the groove structure. The length of the bottom surface of the base plate 3 is 10m, and the width is 5m; the base plate 3 is a rigid base material, and the thickness of the bottom surface of the base plate 3 is 7cm; the adhesive layer 2 is emulsified asphalt or hot asphalt, and the thickness of the adhesive layer 2 is 3cm; the asphalt layer 1 The thickness is 12cm; hot asphalt is used to fill the joints between every two asphalt prefabricated blocks 10; the asphalt layer 1 is composed of modified asphalt, crushed stones and additives; modified asphalt is the use of low-grade sulfur and SBS to modify the base asphalt Obtained; crush...

Embodiment 2

[0054] An assembled asphalt prefabricated block 10, comprising a bottom plate 3, an adhesive layer 2 and an asphalt layer 1 from bottom to top; the shape of the asphalt prefabricated block 10 is a cube, the bottom plate 3 is a groove structure with an upper end opening, the adhesive layer 2 and the asphalt layer Layers 1 are both arranged in a groove structure. The length of the bottom surface of the base plate 3 is 5m, and the width is 1m; the base plate 3 is a rigid base material, and the thickness of the bottom surface of the base plate 3 is 0.2cm; the adhesive layer 2 is emulsified asphalt or hot asphalt, and the thickness of the adhesive layer 2 is 1cm; The thickness of layer 1 is 1cm; between every two asphalt prefabricated blocks 10, hot asphalt is used for caulking; asphalt layer 1 is composed of modified asphalt, crushed stones and additives; sex; crushed rocks include limestone and dolomite flour.

[0055] Wherein, the asphalt layer 1 is calculated in parts by weigh...

Embodiment 3

[0069] An assembled asphalt prefabricated block 10, which includes a bottom plate 3, an adhesive layer 2 and an asphalt layer 1 from bottom to top; the shape of the asphalt prefabricated block 10 is a cuboid, the bottom plate 3 is a groove structure with an upper end opening, the adhesive layer 2 and the asphalt layer Layers 1 are both arranged in a groove structure. The length of the bottom surface of the bottom plate 3 is 15m, and the width is 15m; the bottom plate 3 is a rigid base material, and the thickness of the bottom surface of the bottom plate 3 is 10cm; the adhesive layer 2 is emulsified asphalt or hot asphalt, and the thickness of the adhesive layer 2 is 5cm; the asphalt layer 1 The thickness is 20cm; hot asphalt is used to fill the joints between every two asphalt prefabricated blocks 10; the asphalt layer 1 is composed of modified asphalt, crushed stones and additives; modified asphalt is modified by using low-grade sulfur and SBS to base asphalt Obtained; crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com