Non-ionic epoxy emulsifier, preparation method thereof and waterborne epoxy emulsion

An epoxy emulsifier, non-ionic technology, applied in the field of new materials, can solve the problems of poor emulsion stability, shortened service life and high cost, achieve high practical application value, increase number average molecular weight, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

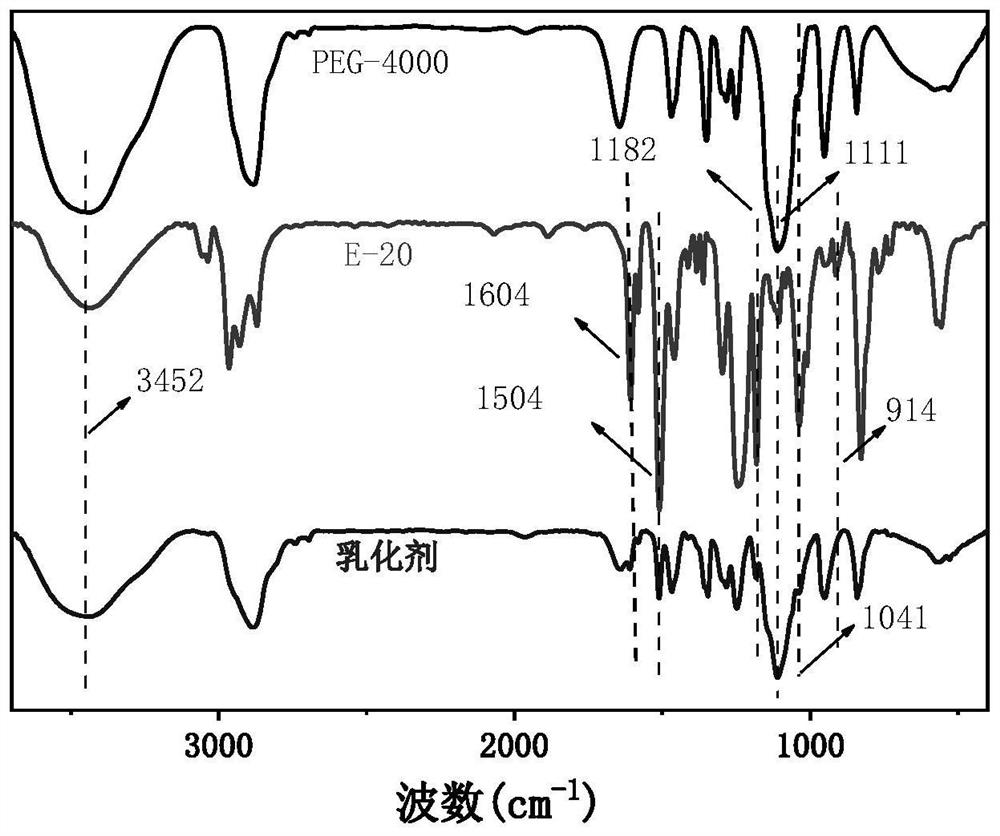

[0093] According to the mass ratio of epoxy resin (E-20) to polyethylene glycol (PEG-4000) is 1:3.8 (epoxy value: hydroxyl value = 1:1), epoxy resin (E-20) and butyl acetate The mass ratio of the ester is 1:1, and the mass of the catalyst boron trifluoride etherate is 0.3% of the mass of the epoxy resin to prepare the emulsifier.

[0094] Step 1. Raw material pretreatment: boron trifluoride diethyl ether complex is treated with 4A molecular sieve; PEG-4000 uses toluene reflux to remove water; E-20 uses toluene reflux to remove water, and the mass ratio of E-20 is 1:1 Mix with butyl acetate to form E-20 dilution.

[0095] Step 2. Add the treated boron trifluoride etherate complex, the treated PEG-4000 and butyl acetate into a four-necked flask equipped with a condenser tube, a thermometer, a mechanical stirrer and a constant pressure dropping funnel, and heat up to 100°C at N 2 The raw materials were fully dissolved under protection, and then the temperature was lowered to 80...

Embodiment 2

[0113] Basically with embodiment one, the only difference is that the consumption of catalyst is 0.2%.

Embodiment 3

[0115] Basically with embodiment one, the only difference is that the consumption of catalyst is 0.4%.

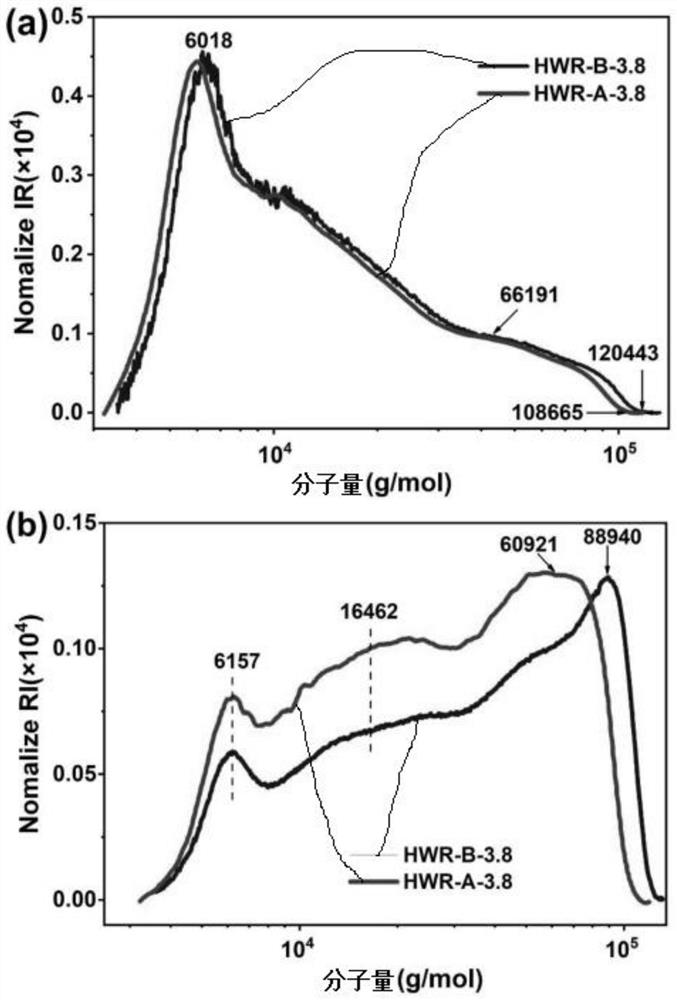

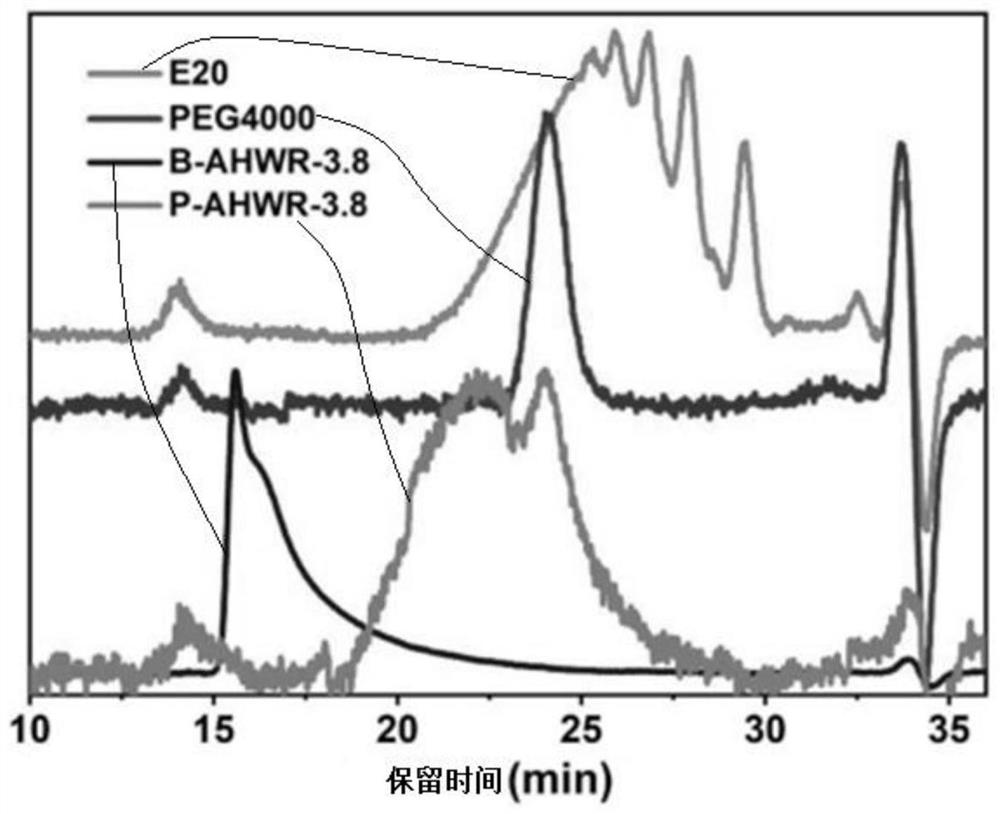

[0116] Taking the normalized differential refractive index signal (Normalized RI) as the ordinate, the molecular weight logarithm (Log 10 M) plotted as abscissa as Figure 4 The curve shown.

[0117] Figure 4 It shows that when the amount of catalyst in the reaction system is 0.2%, the catalytic effect is not ideal, and PEG-4000 does not react with epoxy resin to generate high molecular weight products; when the amount of catalyst is 0.3% and 0.4%, the PEG-4000 The peaks were significantly attenuated and high molecular weight material was produced. If the molecular weight of the emulsifier increases with the amount of catalyst, the molecular weight of the emulsifier should be the largest when the amount of catalyst is 0.4%. However, the molecular weight of the emulsifier and its distribution diagram showed that the molecular weight of the product did not increase furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com