Aliphatic polycarbonate preparation method

A polycarbonate and aliphatic technology, which is applied in the field of preparation of aliphatic polycarbonate, can solve the problems affecting the industrialization process of carbon dioxide and propylene oxide copolymer, the color of the polymer, and the large pressure loss, so as to improve the utilization of equipment The effect of increasing the polymerization rate, increasing the polymerization temperature and reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing aliphatic polycarbonate, which can be realized by appropriately improving process parameters for reference by those skilled in the art. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they all belong to the protection scope of the present invention. The method and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the method and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

[0031] The invention provides a kind of preparation method of aliphatic polycarbonate, comprising

[0032] A heterogeneous catalyst is used to polymerize carbon dioxide, propylene oxide and comonomers at a certain temperature and...

Embodiment 1

[0066] A ternary rare earth catalyst synthesized according to the method provided by Chinese patent ZL 03105023.9; and put into the catalyst at a mass ratio of diethylzinc:propylene oxide of 1:100 to obtain the third monomer: glycidyl methacrylate and styrene copolymer (Molecular weight: 7kg / mol, epoxy equivalent 350g / equivalent) 1kg, put into a 500L polymerization kettle, add 200kg of propylene oxide, 85kg of carbon dioxide, heat to 100°C, the pressure can reach up to 4.3MPa, start timing, and maintain the reaction temperature of 100°C Reaction 5h.

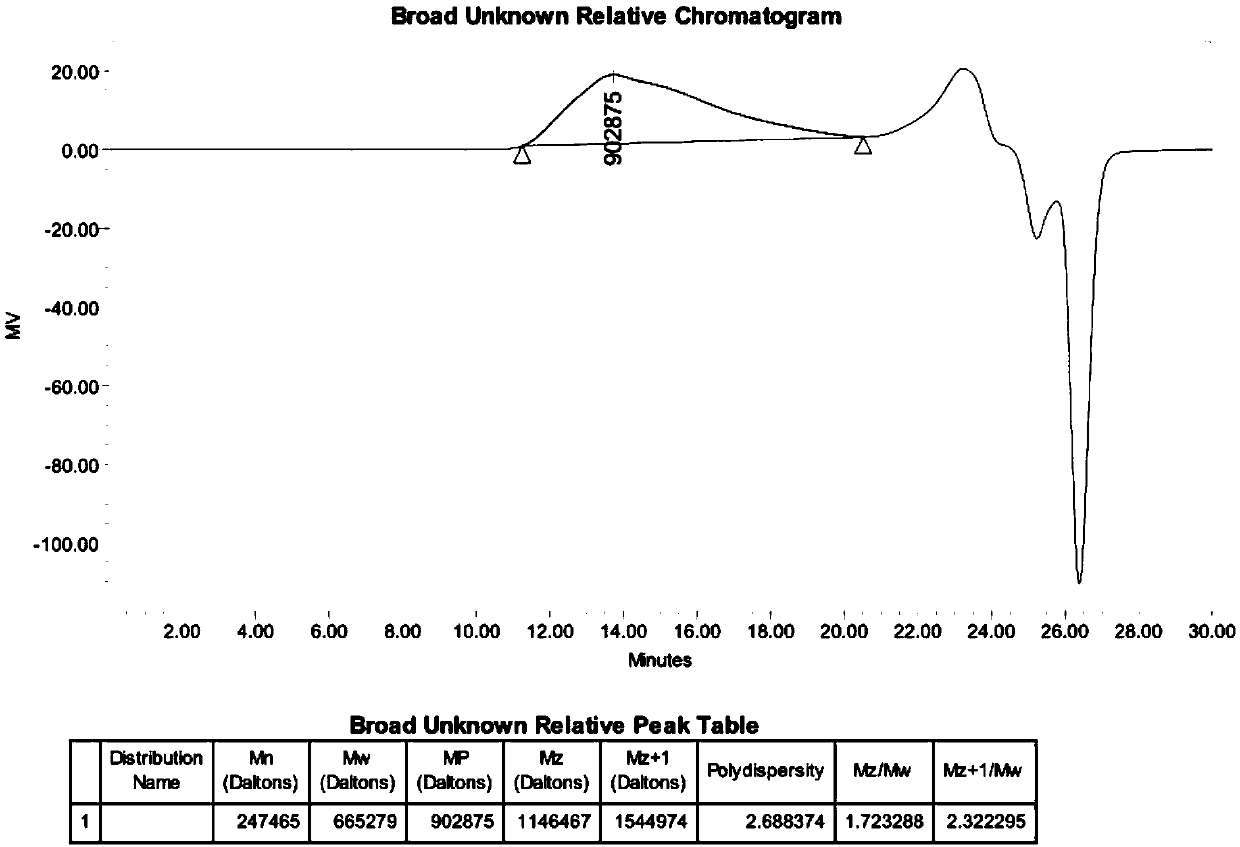

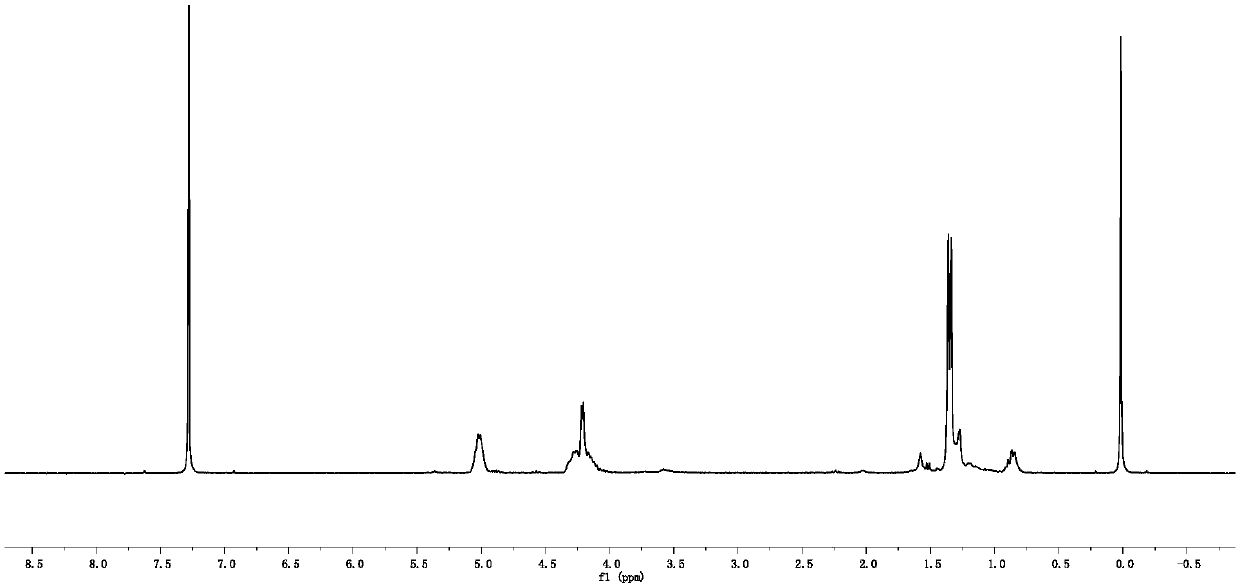

[0067] Cooling water was passed into the internal cooling coil, and after cooling to 30°C rapidly, unreacted propylene oxide and carbon dioxide were removed to obtain 130 kg of carbon dioxide-propylene oxide copolymer and 10.2 kg of cyclic carbonate. Using styrene as the standard sample and dichloromethane as the mobile phase, the weight-average molecular weight of the carbon dioxide-propylene oxide copolymer was measured to be 5...

Embodiment 2

[0069] According to the method of Chinese patent ZL 201510859248.8, the dicarboxylic acid catalyst was prepared, and the catalyst was put into the catalyst according to the catalyst: propylene oxide mass ratio of 1:100, and the third monomer: glycidyl methacrylate copolymer (molecular weight: 20kg / mol, ring Oxygen equivalent (150g / equivalent) 0.2kg, put into a 500L polymerization kettle, add 200kg of propylene oxide, 80kg of carbon dioxide, heat to 120°C, the pressure reaches up to 5.2MPa, start timing, and maintain the reaction temperature of 120°C for 2h.

[0070] Cooling water was passed into the internal cooling coil, and after cooling to 30°C rapidly, unreacted propylene oxide and carbon dioxide were removed to obtain 104 kg of carbon dioxide-propylene oxide copolymer and 5.2 kg of cyclic carbonate. Styrene was used as the standard sample, dichloromethane was used as the mobile phase to measure the molecular weight of the product, and the content of propylene carbonate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com