Preparation method of composite microspheres

A technology of composite microspheres and microspheres, which is applied in the field of preparation of composite microspheres, can solve the problems of large solvent consumption, low yield, and low monomer concentration, and achieve short reaction time, simple equipment, and large heat transfer coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

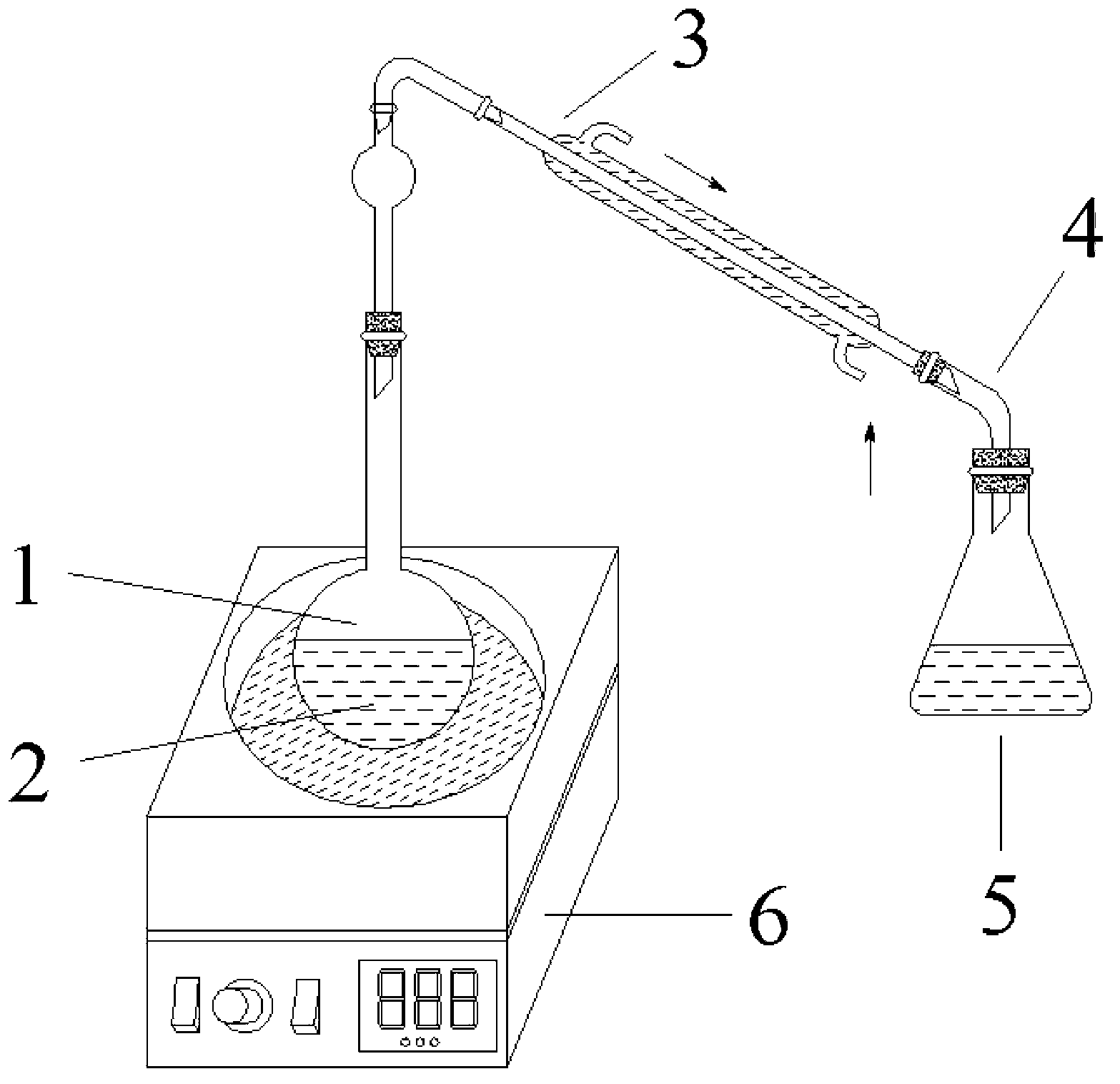

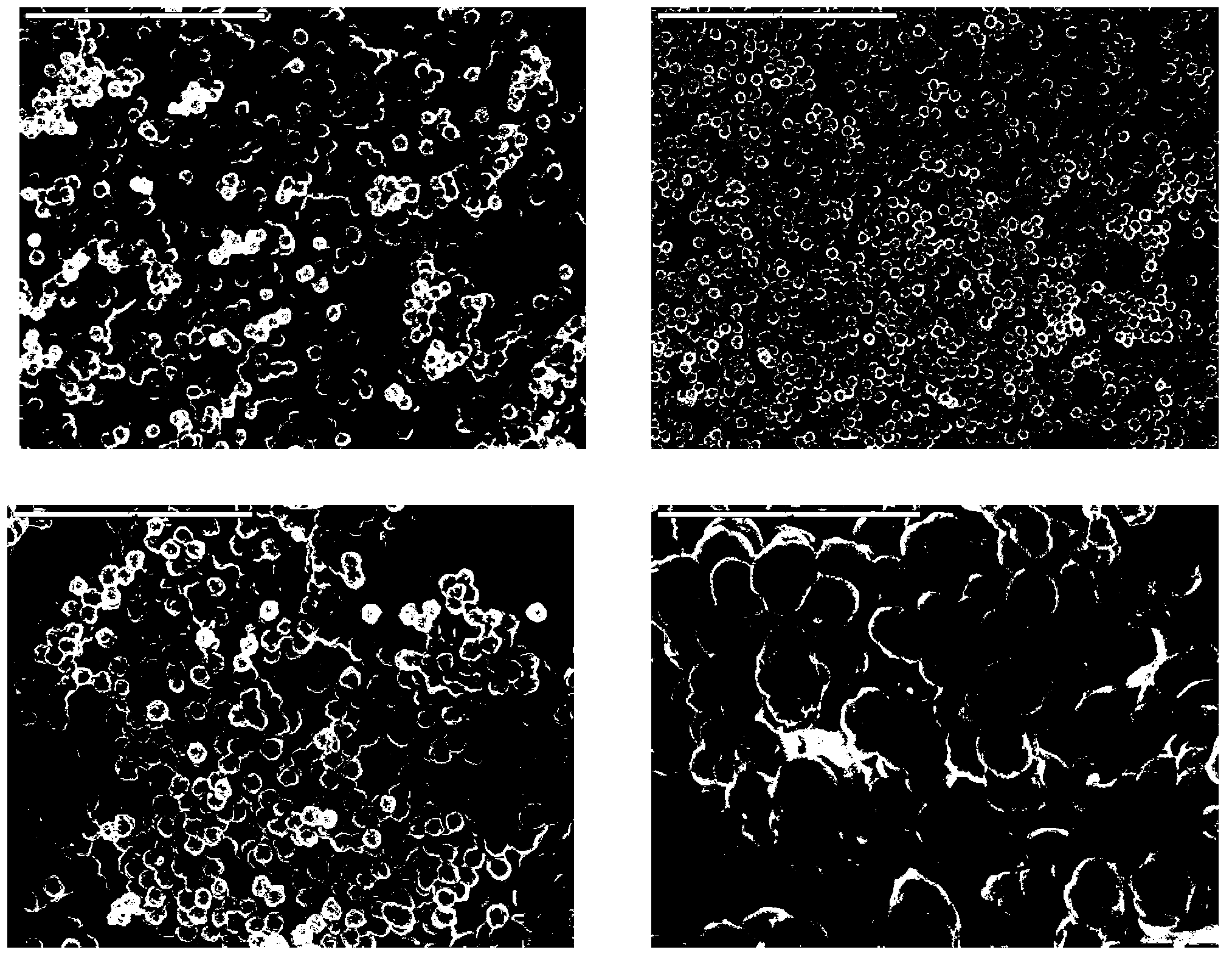

[0029]Take 1 mol of acrylamide and 10 mol of acrylic acid, put them into the single-necked round bottom flask 1 (reaction vessel), add 35.6 mol of acetonitrile solvent into the bottle, mix well, and ultrasonically disperse them, then add 0.1 mol of N-N Methylenebisacrylamide (MBAA), adding 0.02mol of azobisisobutyronitrile (AIBN) is also ultrasonically dispersed; (2) The round bottom flask containing the reaction solution 2 is placed in an oil bath (heating device 6) , tilt downward at a certain angle, such as 30°, and install the condensing return pipe 3, the condensing joint 4 and the receiving container 5; (3) The oil bath starts to heat up, and rises from normal temperature to boiling within 15 minutes. Keep it at about 90°C for 15 minutes; (4) Adjust the temperature of the oil bath to 110°C, increase the distillation intensity, and the solvent in the flask will continuously flow into the receiving container. After about 90 minutes, the solvent in the flask Almost all are ...

Embodiment 2

[0031] Take 10 mol of acrylamide and 1 mol of 2-acrylamido-methylpropanesulfonic acid (AMPS), add them into a single-necked round bottom flask, add 173 mol of acetonitrile solvent into the bottle, mix well, disperse it by ultrasonic, and put it into the round bottom flask Add 0.1mol of divinylbenzene to the flask, add 0.05mol of Azobisisoheptanonitrile Also ultrasonically disperse; (2) Place the round-bottomed flask containing the reaction liquid in the oil bath (heating device) and tilt it downward at a certain angle, such as 30°, and install the condensing return pipe, condensing joint and receiving container; (3 ) The oil bath starts to heat up, and rises from normal temperature to boiling within 18 minutes. The temperature of the oil bath is kept at about 90°C, and remains in this state for 15 minutes; (4) Adjust the temperature of the oil bath to 120°C, and increase the distillation intensity , the solvent in the flask continuously flowed into the receiving container, and...

Embodiment 3

[0033] Take 1 mol of acrylamide and 5 mol of methyl methacrylate (MMA), put them into a single-necked round-bottomed flask, add 24.4 mol of acetonitrile solvent into the bottle, mix well, and disperse by ultrasonic, then add 0.05 mol into the round-bottomed flask N-N methylene bisacrylamide (MBAA), adding 0.01mol dimethyl azobisisobutyrate is also ultrasonically dispersed; (2) The round bottom flask containing the reaction solution is placed in an oil bath (heating device) In the middle, tilt down at a certain angle, such as 30°, and install the condensing return pipe, condensing joint and receiving container; (3) The oil bath starts to heat up, and rises from normal temperature to boiling within 10 minutes, and the temperature of the oil bath is maintained at 90 ℃, keep this state for 15 minutes; (4) adjust the temperature of the oil bath to 115 ℃, increase the distillation intensity, and the solvent in the flask will continuously flow into the receiving container. After about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com