A kind of capacitor composite electrolyte and its preparation method and application

A composite electrolyte and capacitor technology, applied in the direction of hybrid capacitor electrolytes, etc., can solve the problems of poor mechanical properties such as brittleness and tensile properties of composite electrolytes, rupture of composite electrolytes, and reduced yield, etc., and achieve excellent electrochemical performance and shortened reaction time. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

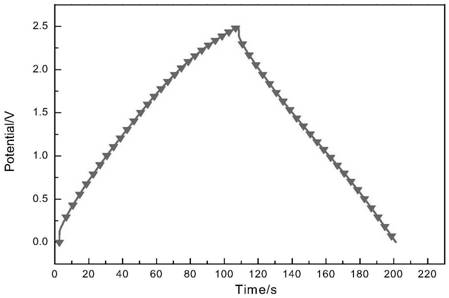

[0044] As a method for preparing a capacitor composite electrolyte according to an embodiment of the present invention, the method includes the following steps:

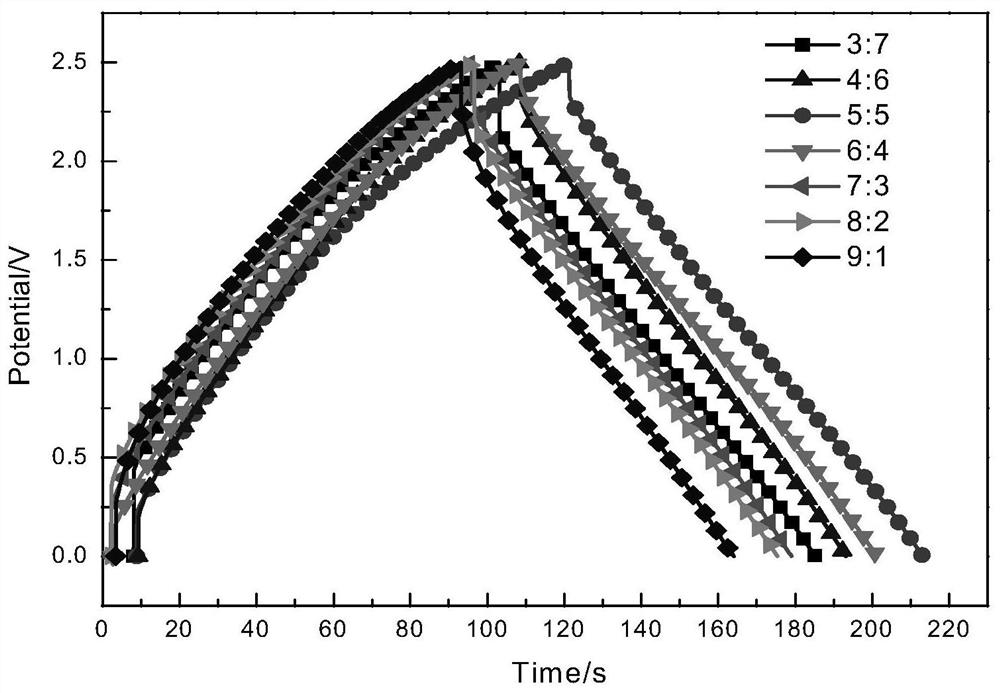

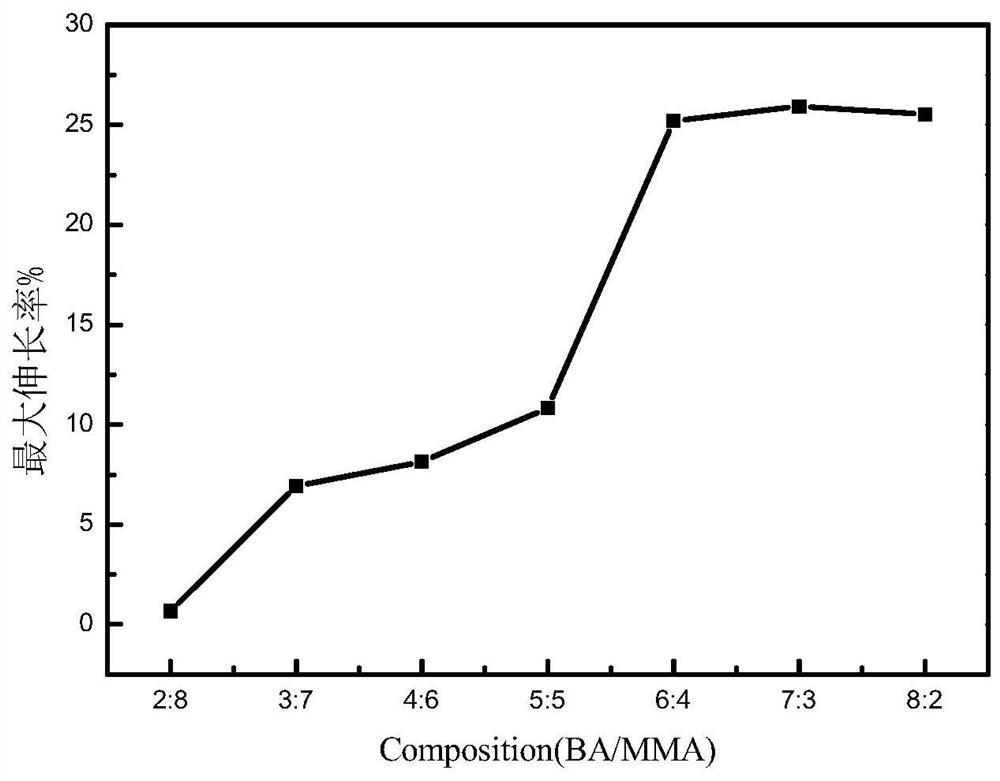

[0045] (1) Add 70mL of distilled water to a 250mL three-necked flask, and then add 12g of butyl acrylate (BA), 8g of methyl methacrylate (MMA) (that is, the weight ratio BA:MMA=6:4), and 0.2g of methacrylic acid as a dispersant Sodium lauryl sulfate and 2mL of dipropylene phthalate as a crosslinking agent to obtain a mixed system A;

[0046] (2) Install an oil bath, a reflux condenser, a stirrer, a constant pressure funnel and a three-necked flask, stir the mixed system A quickly and raise the temperature to 85°C, and add 7.5mL of 2.6 to the mixed system A after the temperature is stabilized at 85°C mg / L ammonium persulfate aqueous solution as the initiator, after the solution turns blue, continue to drop 22.5mL of 2.6mg / L initiator solution, after adding the initiator, the temperature is raised to 90°C for 3 hours o...

Embodiment 2

[0052] As a method for preparing a capacitor composite electrolyte according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the weight ratio BA:MMA=3:7.

Embodiment 3

[0054] As a method for preparing a capacitor composite electrolyte according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the weight ratio BA:MMA=4:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com