Low-cost polyester polycarboxylic acid water reducer

A technology of polyester-type polycarboxylic acid and water reducer, applied in the field of water reducer, can solve the problems that hinder the development of PEG synthetic water reducer, difficult separation of esterification products, etc., and achieve the effect of easy separation and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

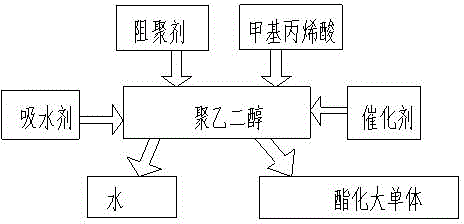

[0043] Example 1 Preparation of esterified macromonomer polyethylene glycol methacrylate (esterification reaction)

[0044] Add 50g polyethylene glycol (molecular weight: 400) and 0.3g hydroquinone successively into a 250ml three-necked flask equipped with a dropping device, a thermometer, and a condenser, stir, and after heating up to 60°C, add 0.6g p-methyl Benzenesulfonic acid, 9.2g of silica gel, after hydroquinone and p-toluenesulfonic acid are completely dissolved, add methacrylic acid drop by drop (11.6g of methacrylic acid in total), and raise the temperature to 110°C within 2-3h After heat preservation, stop heating when the esterification rate is 52%, continue to store the product in the oil bath, let it slowly cool down to room temperature, and then pour out the upper layer of ester liquid (that is, the esterified macromonomer polyethylene glycol methacrylate) Stand-by, the lower layer of pale yellow solid is solidified silica gel, which contains less esters, which ...

Embodiment 2

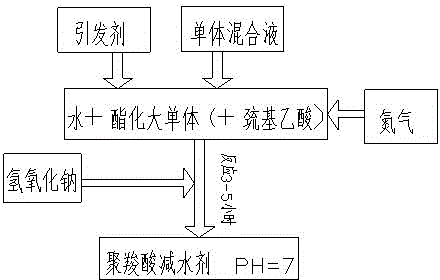

[0045] Example 2 Preparation of low-cost polyester polycarboxylate water reducer A0 (polymerization grafting reaction)

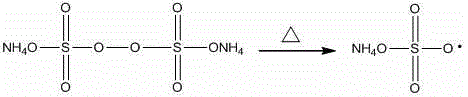

[0046] In a three-neck flask equipped with a condensation reflux device and two sets of dropping devices, add 0.1g of chain transfer agent mercaptoacetic acid, dissolve it in a small amount of distilled water, and inject nitrogen to drive away the air (very low flow rate, 2-3 bubbles per second) ), heated and stirred to 80°C, while slowly adding the aqueous solution of the initiator (dissolve 0.46g of the initiator ammonium persulfate in water, the concentration is 0.25%), while adding the aqueous solution of the mixed monomer (the mixed monomer is 10g by the implementation Example 1 The esterified macromonomer polyethylene glycol methacrylate, 1.0gMAA, and 0.5gSMAS mixed solution obtained by the esterification reaction, the concentration of the mixed monomer aqueous solution is 25%), after about 1-2h, dropwise, continue to maintain After constant temperatur...

Embodiment 3

[0048] Example 3 Preparation of low-cost polyester polycarboxylate water reducer A1 (polymerization grafting reaction)

[0049] In a three-neck flask equipped with a condensation reflux device and two sets of dropping devices, add 0.1g of chain transfer agent mercaptoacetic acid, dissolve it in a small amount of distilled water, and inject nitrogen to drive away the air (very low flow rate, 2-3 bubbles per second) ), heated and stirred to 80°C, while slowly adding the initiator aqueous solution (0.047g of the initiator ammonium persulfate and 0.156g of the initiator auxiliary agent 30% hydrogen peroxide dissolved in water, the concentration was 0.25%), while adding the mixed mono Aqueous solution (mixed monomer is the mixed solution of 10g esterified macromer polyethylene glycol methacrylate, 1.0gMAA, 0.2gAM and 0.5gSMAS obtained by the esterification reaction of embodiment 1, and the concentration of mixed monomer aqueous solution is 25 %), about 1-2h after adding dropwise, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com