Organic electroluminescent compound, preparation method thereof and organic electroluminescent device

A technology of luminescence and compounds, applied in the field of organic electroluminescent compounds and their preparation, and organic electroluminescent devices, which can solve the problems of reducing device performance and achieve the effects of reducing performance, improving thermal stability and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

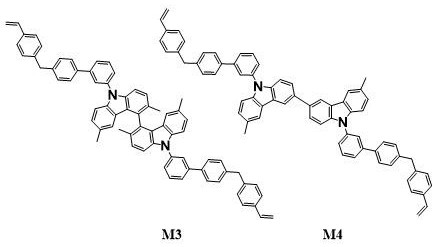

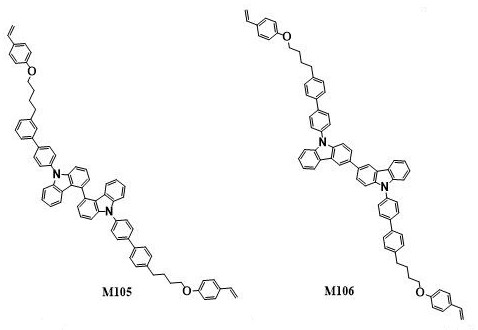

Image

Examples

Embodiment 1

[0180] Preparation of organic electroluminescent compound M1:

[0181] ;

[0182] ;

[0183] ;

[0184] .

[0185] Preparation of Intermediate A1: Add 4-bromocarbazole (10 mmol), pinacol diborate (5 mmol), potassium carbonate (10 mmol) and THF (ie Tetrahydrofuran, 50 ml), heated to reflux for 24h. After the reaction, the reaction solution was filtered, then extracted and separated, and then the reaction solution was separated and purified with a silica gel chromatographic column, and the product was collected by rotary evaporation to remove the solvent, and finally vacuum-dried at room temperature for 12 h to obtain intermediate A1, weighed, and the yield was About 84%.

[0186] Preparation of Intermediate A2: Under nitrogen atmosphere, Intermediate A1 (10 mmol), 4'-bromo-3-iodo-1,1'biphenyl (9.78 mmol), potassium carbonate ( 20 mmol), copper powder (40 mmol) and DMF (that is, N,N-dimethylformamide, 50 ml), heated to reflux for 18h. After the reaction, the react...

Embodiment 2

[0190] Preparation of organic electroluminescent compound M2:

[0191] ;

[0192] ;

[0193] .

[0194] Preparation of Intermediate B1: Add 3,3'-bicarbazole (9.78 mmol), 4'-bromo-3-iodo-1,1'biphenyl (9.78 mmol), potassium carbonate (20 mmol), copper powder (40 mmol) and DMF (50 ml), heated to reflux for 18h. After the reaction, the reaction solution was filtered, then extracted and separated, and then the reaction solution was separated and purified with a silica gel chromatography column, and the product was collected by rotary evaporation to remove the solvent, and finally vacuum-dried at room temperature for 12 hours to obtain intermediate B1, weighed, and the yield was About 80%.

[0195] Preparation of intermediate B2: Add intermediate B1 (8 mmol), triisopropyl borate (8 mmol), n-butyllithium (8 mmol) and THF (50 ml) to a 100 ml two-necked flask under nitrogen atmosphere , heated to reflux for 12h. After the reaction, the reaction solution was filtered, then e...

Embodiment 3

[0198] Preparation of organic electroluminescent compound M8:

[0199] ;

[0200] ;

[0201] .

[0202] Preparation of intermediate C1: Add 3,3'-tert-butyl-6,6'-bicarbazole (10 mmol), 4'-bromo-3-iodo -1,1'biphenyl (10 mmol), potassium carbonate (20 mmol), copper powder (40 mmol) and DMF (50 ml), heated to reflux for 18h. After the reaction, the reaction solution was filtered, then extracted and separated, and then the reaction solution was separated and purified with a silica gel chromatographic column, and the product was collected by rotary evaporation to remove the solvent, and finally vacuum-dried at room temperature for 12 h to obtain intermediate C1, weighed, and the yield was About 77%.

[0203] Preparation of intermediate C2: Add intermediate C1 (8 mmol), triisopropyl borate (8 mmol), n-butyllithium (8 mmol) and THF (50 ml), heated to reflux for 12h. After the reaction, the reaction solution was filtered, then extracted and separated, and then the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com