Novel wall heat-insulating material and preparation process thereof

A technology for thermal insulation materials and walls, which is applied in the field of building materials, and can solve the problems that the interface of plant fiber premixed into the soil is not tightly connected, which affects the compressive strength and thermal insulation performance of thermal insulation materials, and affects the durability and mechanical properties of thermal insulation materials. , to achieve the effect of improving interface connection, improving sag resistance and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

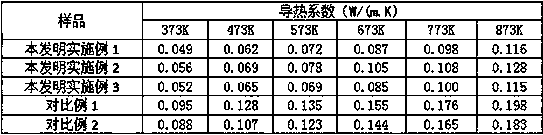

Examples

Embodiment 1

[0053] The novel wall insulation material of the present embodiment, in parts by weight, the insulation material mainly includes the following components:

[0054] 20 parts of cement;

[0055] 18.5 parts of polyvinyl chloride resin powder;

[0056] 20 parts of modified plant straw powder;

[0057] 6.5 parts of dispersible latex powder;

[0058] 5 parts of hydroxypropyl methylcellulose;

[0059] 2.8 parts of glass microspheres;

[0060] 1.2 parts of water reducer;

[0061] 2.2 parts of coagulant;

[0062] 0.8 parts of curing agent.

[0063] The cement of this embodiment is selected from white cement.

[0064] The preparation method of the modified plant straw powder of the present embodiment is as follows:

[0065] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0066](2) Dry the straw powder until the moisture content is within 5%, put it into the reactor, and add gelatin ...

Embodiment 2

[0077] The novel wall insulation material of the present embodiment, in parts by weight, the insulation material mainly includes the following components:

[0078] 22 parts of cement;

[0079] 14 parts of polyvinyl chloride resin powder;

[0080] 13 parts of modified plant straw powder;

[0081] 3 parts of dispersible latex powder;

[0082] 2 parts of hydroxypropyl methylcellulose;

[0083] 1.3 parts of glass microspheres;

[0084] 0.3 parts of water reducer;

[0085] 0.5 parts of coagulant;

[0086] Curing agent 0.2 parts.

[0087] The cement of the present embodiment is selected from white cement.

[0088] The preparation method of the modified plant straw powder of the present embodiment is as follows:

[0089] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0090] (2) Dry the straw powder until the moisture content is within 5%, put it into the reactor, and add gelatin...

Embodiment 3

[0101] A new type of wall insulation material, in parts by weight, the insulation material mainly includes the following components:

[0102] 42 parts of cement;

[0103] 23 parts of polyvinyl chloride resin powder;

[0104] 26 parts of modified plant straw powder;

[0105] 10 parts of dispersible latex powder;

[0106] 8 parts of hydroxypropyl methylcellulose;

[0107] 6.5 parts of glass microspheres;

[0108] 2.2 parts of water reducer;

[0109] 3.8 parts of coagulant;

[0110] 1.4 parts of curing agent.

[0111] The cement of the present embodiment is selected from white cement.

[0112] The preparation method of the modified plant straw powder of the present embodiment is as follows:

[0113] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0114] (2) Dry the straw powder until the moisture content is within 5%, put it into the reaction kettle, and add gelatin emulsion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com