Method for testing rock microcracks

A technology of micro-cracks and rocks, applied in the direction of material impedance, can solve the problems of poor anti-corrosion materials, etc., and achieve the effects of easy operation, high detection accuracy and simple detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

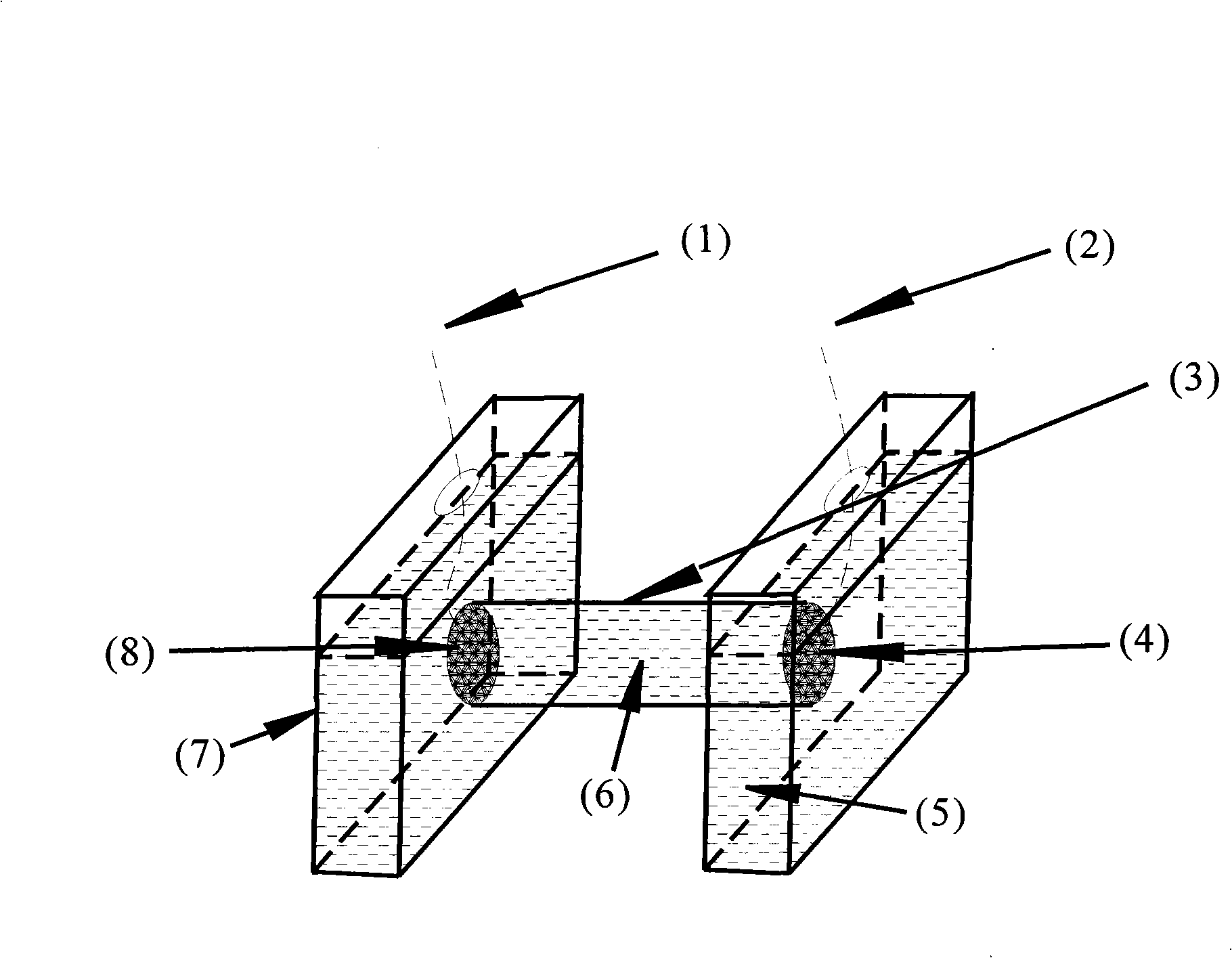

Method used

Image

Examples

Embodiment 1

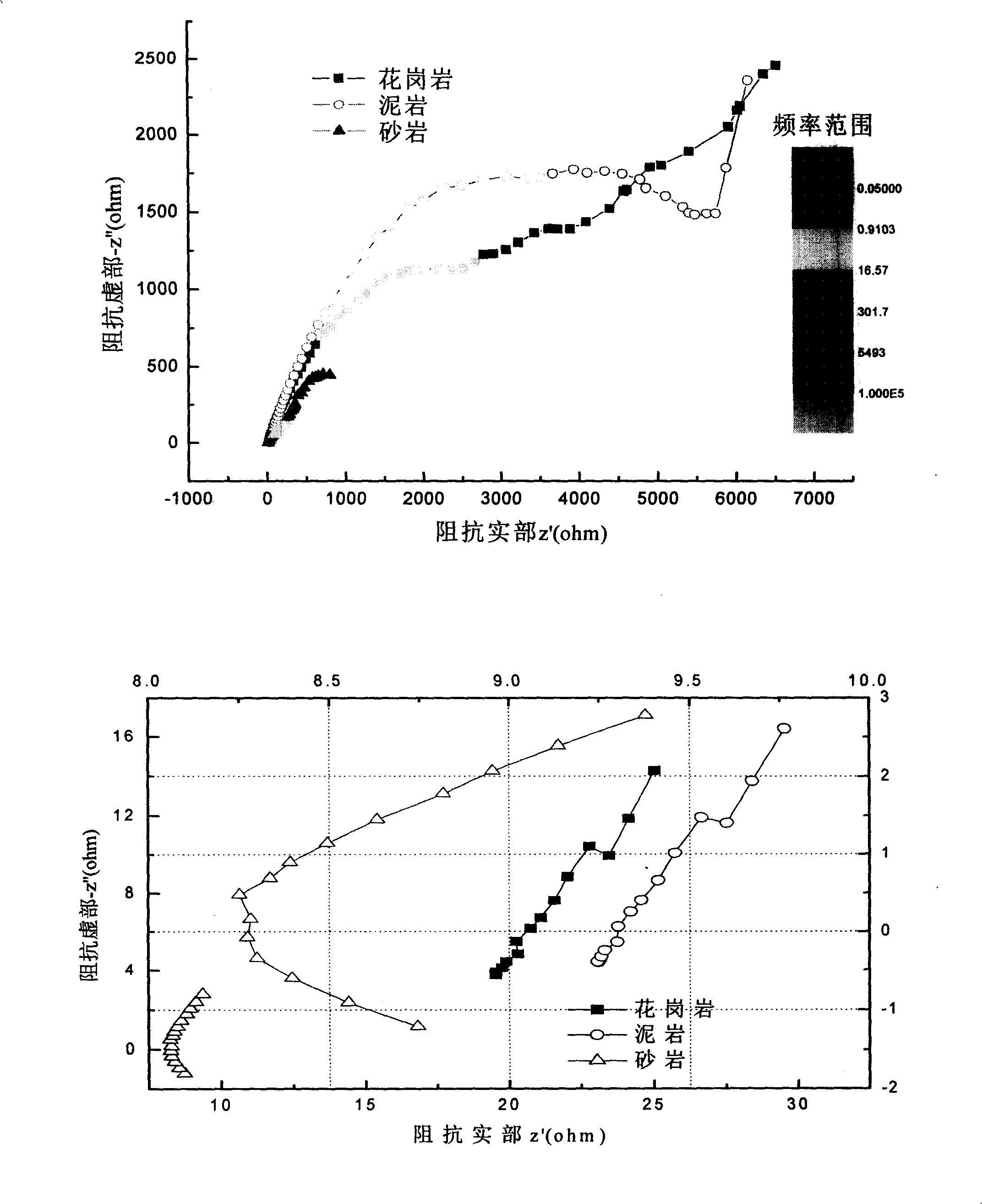

[0029] Example 1: Take granite from a certain project in Sanya, sandstone and mudstone from a certain project in Shanxi, and make a φ50×20 sample, test its AC impedance spectrum, see attached table 1, and get the porosity in order of sandstone>granite>mudstone . Such as figure 2shown.

Embodiment 2

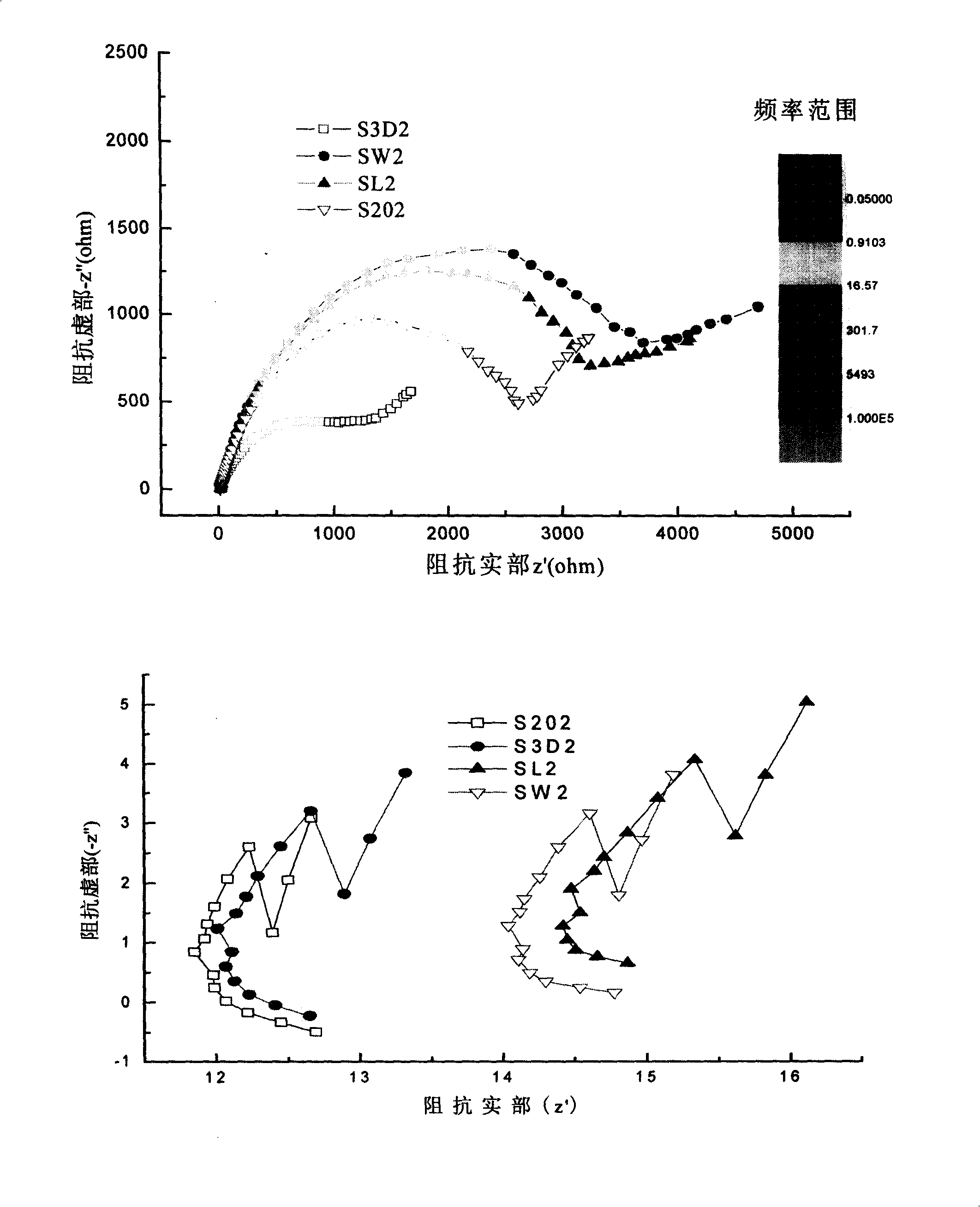

[0031] Take the sandstone of a certain project, make a sample of φ50×50, and test its AC impedance spectrum, see attached table 2, it is obtained that the porosity is in the order of S3D2>S202>SL2>SW2. Such as image 3 shown.

Embodiment 3

[0033] Take the mudstone of a certain project, make a sample of φ50×50, and test its AC impedance spectrum, see the attached manual Figure 4 , the porosity is obtained in order of M2402 Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com