Preparation method of hard film anti-rust oil with high hardness

A technology of anti-rust oil and high hardness, used in the petroleum industry, lubricating compositions, etc., can solve the problem of low hardness of hard film anti-rust oil, and achieve the effect of good hardness and good rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

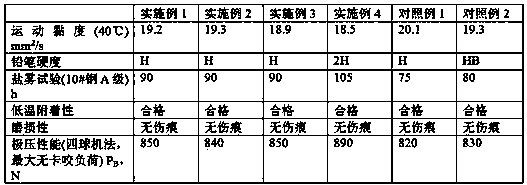

Examples

Embodiment 1

[0030] A kind of preparation method of the high hard film antirust oil of hardness, comprises the steps:

[0031] The 1st step, with light diesel oil 120Kg, beeswax 20Kg, turpentine 10Kg, sunflower oil 5Kg, polyoxyalkylene glycol 4Kg, castor oil oxypropylene polymer 4Kg, triethanolamine 5Kg, ceresin 10Kg, ethyl acetate 30Kg, Stir 3Kg of nonionic surfactant evenly, heat and keep warm, the heating temperature is 70°C, the holding time is 1h, stir evenly, and obtain the first mixture;

[0032] Step 2: Add 4Kg of barium petroleum sulfonate to 4Kg of ethylene glycol, then add 2Kg of diethylene glycol, 30Kg of kerosene and 5Kg of styrene-acrylic emulsion in turn, heat and keep warm, the heating temperature is 50°C, the holding time is 1h, and stir evenly , to get the second mixture;

[0033] Step 3: Mix the first mixture with the second mixture, add 1Kg of defoamer, 1Kg of antioxidant, 1Kg of thixotropic agent, and 1Kg of rust inhibitor, and stir evenly.

[0034] Antifoaming agent...

Embodiment 2

[0037] A kind of preparation method of the high hard film antirust oil of hardness, comprises the steps:

[0038] The 1st step, with light diesel oil 130Kg, beeswax 25Kg, turpentine 13Kg, sunflower oil 6Kg, polyoxyalkylene glycol 5Kg, castor oil oxypropylene polymer 7Kg, triethanolamine 7Kg, ceresin 15Kg, ethyl acetate 40Kg, Stir 5Kg of nonionic surfactant evenly, heat and keep warm, the heating temperature is 76°C, the holding time is 2h, stir evenly, and obtain the first mixture;

[0039] Step 2: Add 5Kg of barium petroleum sulfonate to 5Kg of ethylene glycol, then add 3Kg of diethylene glycol, 35Kg of kerosene and 7Kg of styrene-acrylic emulsion in turn, heat and keep warm, the heating temperature is 60°C, the holding time is 2h, and stir evenly , to get the second mixture;

[0040] Step 3: Mix the first mixture with the second mixture, add 1Kg of defoamer, 1Kg of antioxidant, 1Kg of thixotropic agent, and 1Kg of rust inhibitor, and stir evenly.

[0041] Antifoaming agent...

Embodiment 3

[0044] A kind of preparation method of the high hard film antirust oil of hardness, comprises the steps:

[0045] The 1st step, with light diesel oil 150Kg, beeswax 30Kg, turpentine 15Kg, sunflower oil 10Kg, polyoxyalkylene glycol 6Kg, castor oil oxypropylene polymer 8Kg, triethanolamine 10Kg, ceresin 20Kg, ethyl acetate 50Kg, Stir 6Kg of nonionic surfactant evenly, heat and keep warm, the heating temperature is 80°C, the holding time is 3h, stir evenly, and obtain the first mixture;

[0046] Step 2: Add 8Kg of barium petroleum sulfonate to 8Kg of ethylene glycol, then add 4Kg of diethylene glycol, 40Kg of kerosene and 10Kg of styrene-acrylic emulsion in turn, heat and keep warm, the heating temperature is 70°C, the holding time is 3h, and stir evenly , to get the second mixture;

[0047] Step 3: Mix the first mixture with the second mixture, add 2Kg of defoamer, 2Kg of antioxidant, 2Kg of thixotropic agent, and 2Kg of rust inhibitor, and stir evenly.

[0048] Antifoaming ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com