Fischer-Tropsch wax and hydrocarbon mixtures for transport (law938)

a technology of hydrocarbon mixture and wax, which is applied in the direction of oxygen-containing compound preparation, gaseous mixture working up, separation process, etc., can solve the problems of difficult to find solvents in remote locations, and the above-mentioned conventional methods for shipping wax are often unavailabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

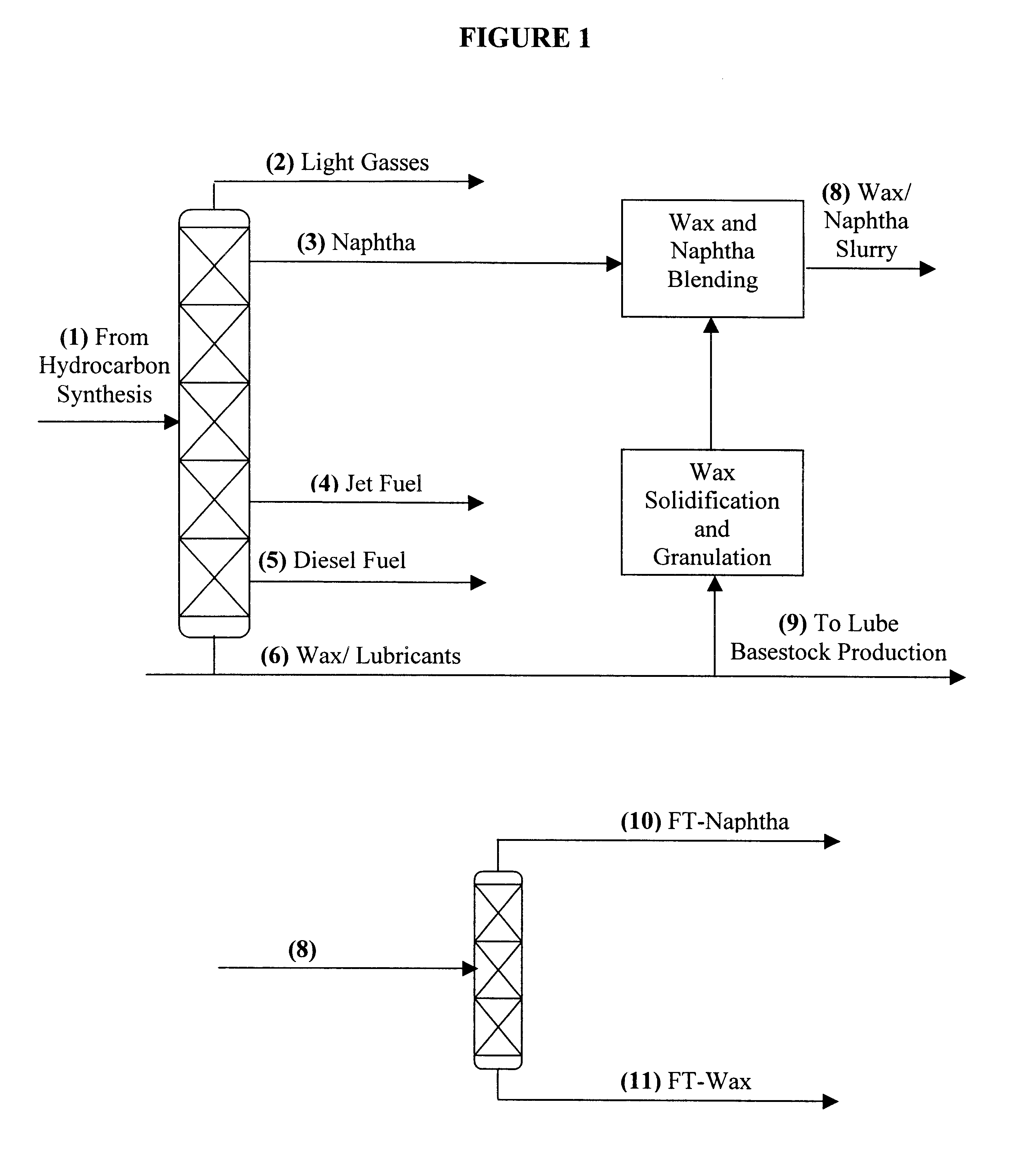

Fischer-Tropsch synthesis product was fractionated to obtain naphtha with a boiling range from about 95.degree. F. to about 320.degree. F. The quality of separation was measured by High Temperature Simulated Distillation Gas Chromatography (GCD) using a HP 6890 series gas chromatograph. The wax was the total solid product from the Fischer-Tropsch synthesis at ambient conditions with a boiling range of 453.degree. F. to 1129.degree. F. based on 5 and 95 weight percent GCD, respectively. The GCD data are presented in Table 1 below.

The mixtures were produced by granulating the wax into finely divided flakes and then mixing the wax with the naphtha in a colloid mill with varying rotor-stator gap widths and times. This blending process was repeated for a range of wax concentrations from about 7 to 30 weight percent.

Pour points were measured by an ISL pour point analyzer and the Brookfield viscosity was measured using a viscometer from about 100.degree. F. to the pour point. The results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com