Paraffin fluidization cooling granulation process

A paraffin and process technology, which is applied in the field of paraffin cooling and granulation technology, can solve the problems of large footprint, troublesome maintenance, and large installation volume of the whole set of devices, and achieves the reduction of chilled water consumption, reliable product quality, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

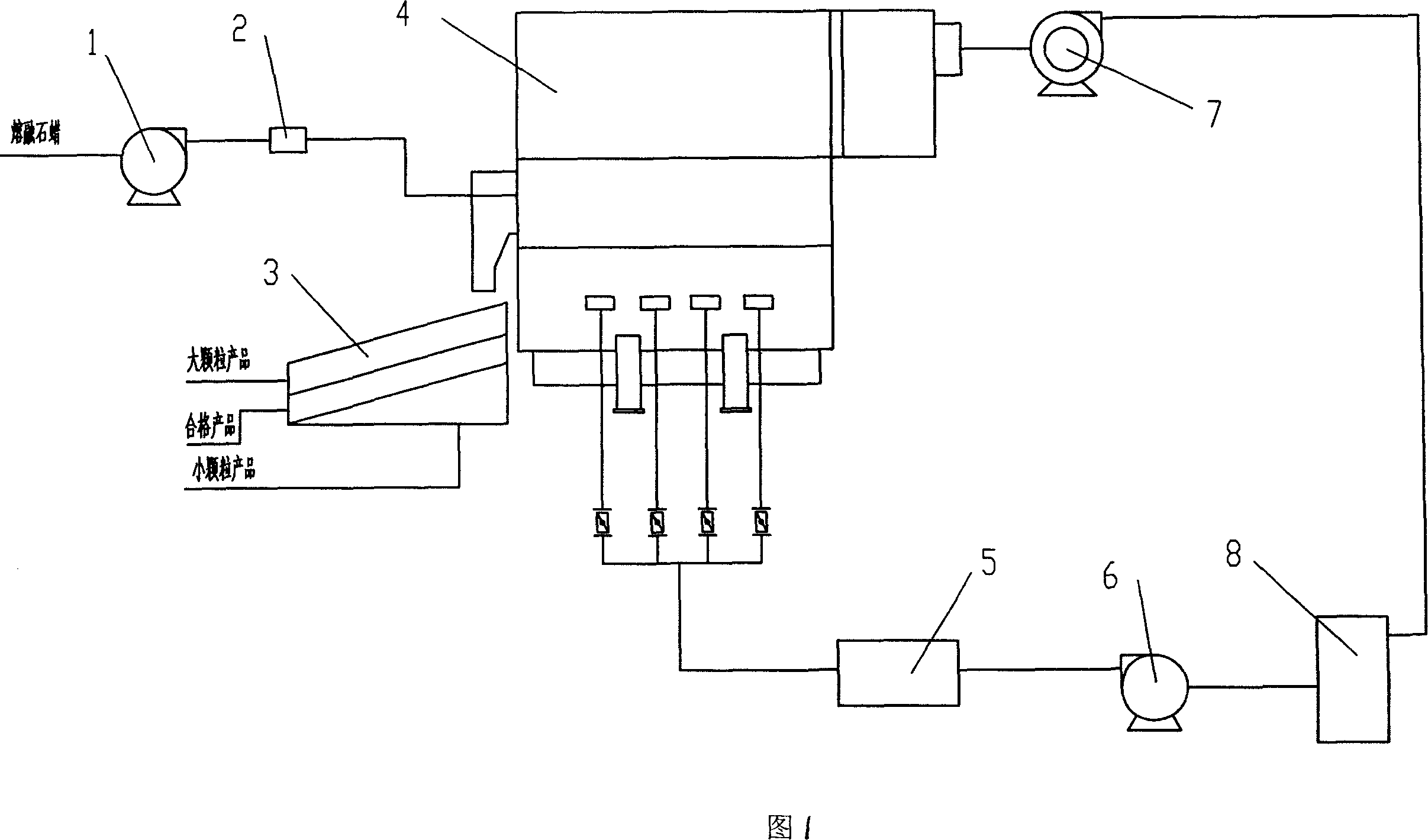

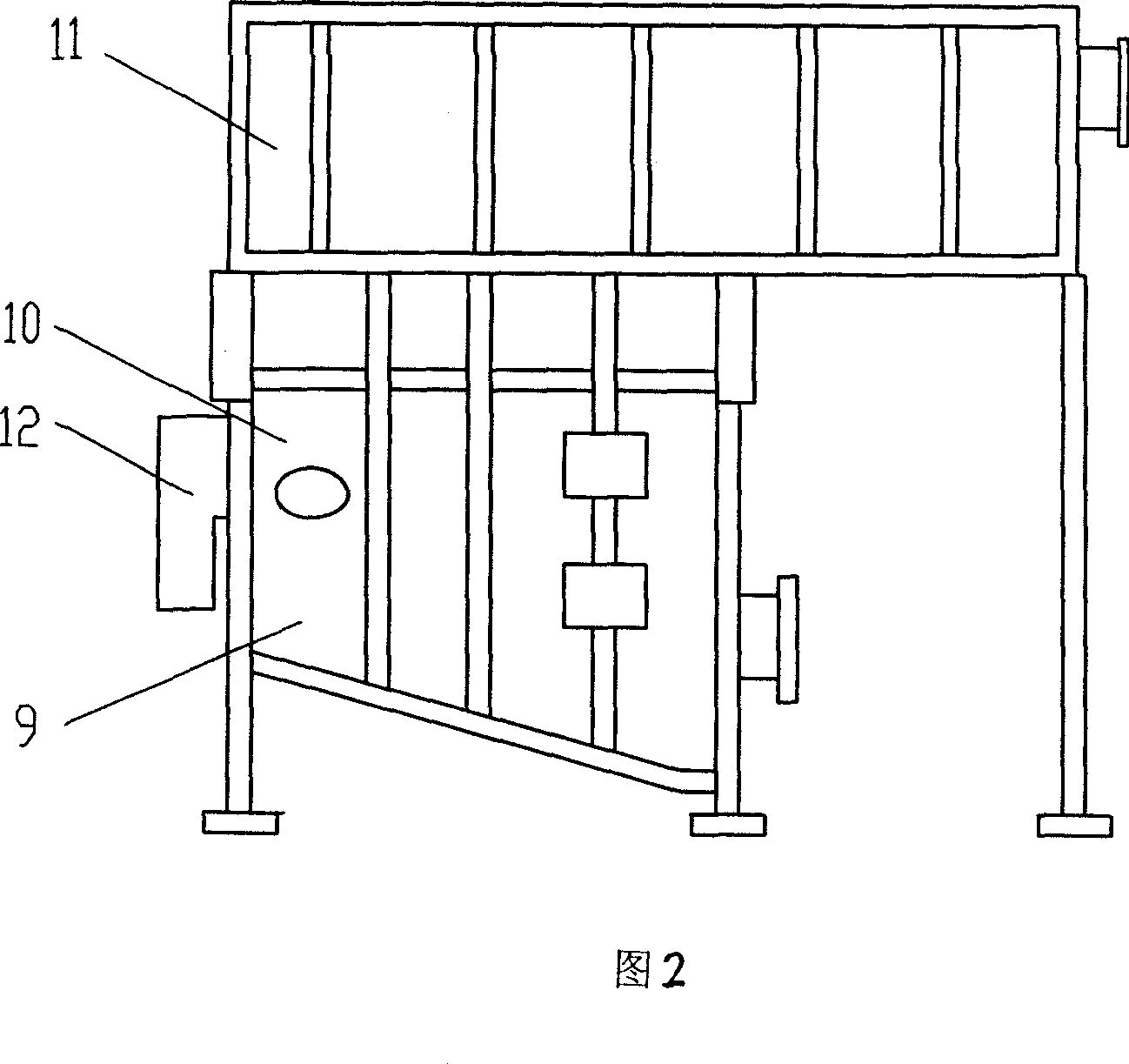

[0011] Fig. 1 has provided the system diagram of realizing technological process of the present invention. The equipment included is feed pump 1, filter 2, screening machine 3, fluidized bed cooler 4, surface cooler and demister 5, blower 6, induced draft fan 7 and air filter 8. The feed pump 1 is connected to the feed pipe of the fluidized bed cooler 4 through the filter 2 , and the surface cooler and demister 5 are connected to the downwind chamber 9 of the fluidized bed cooler 4 . The surface cooler and demister 5 are used to generate cold air, and the circulating frozen salt water of about -15 degrees is passed in the surface cooler as the cooling medium, so that the air temperature is reduced to below 15 degrees. The built-in bag filter of the fluidized bed cooler 4, the induced draft fan 7, the air filter 8, the blower 6, the surface cooler and the mist eliminator 5 are connected in sequence. Feed pump 1, filter 2, screening machine 3, surface cooler and demister 5, blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com