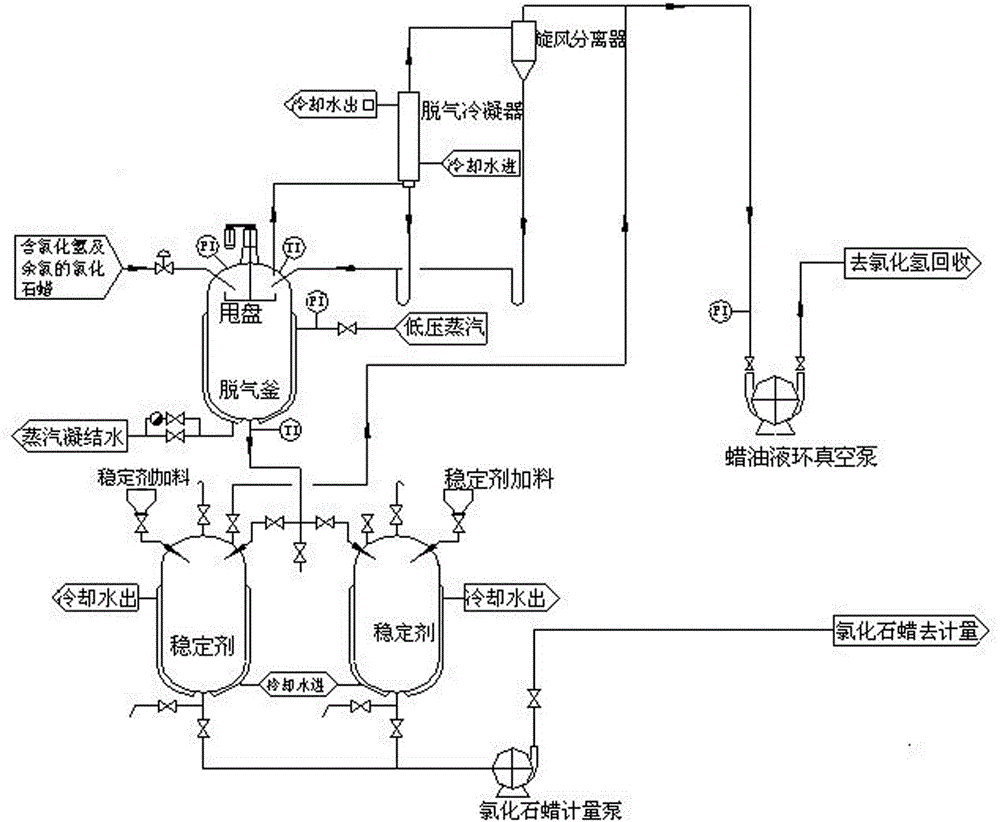

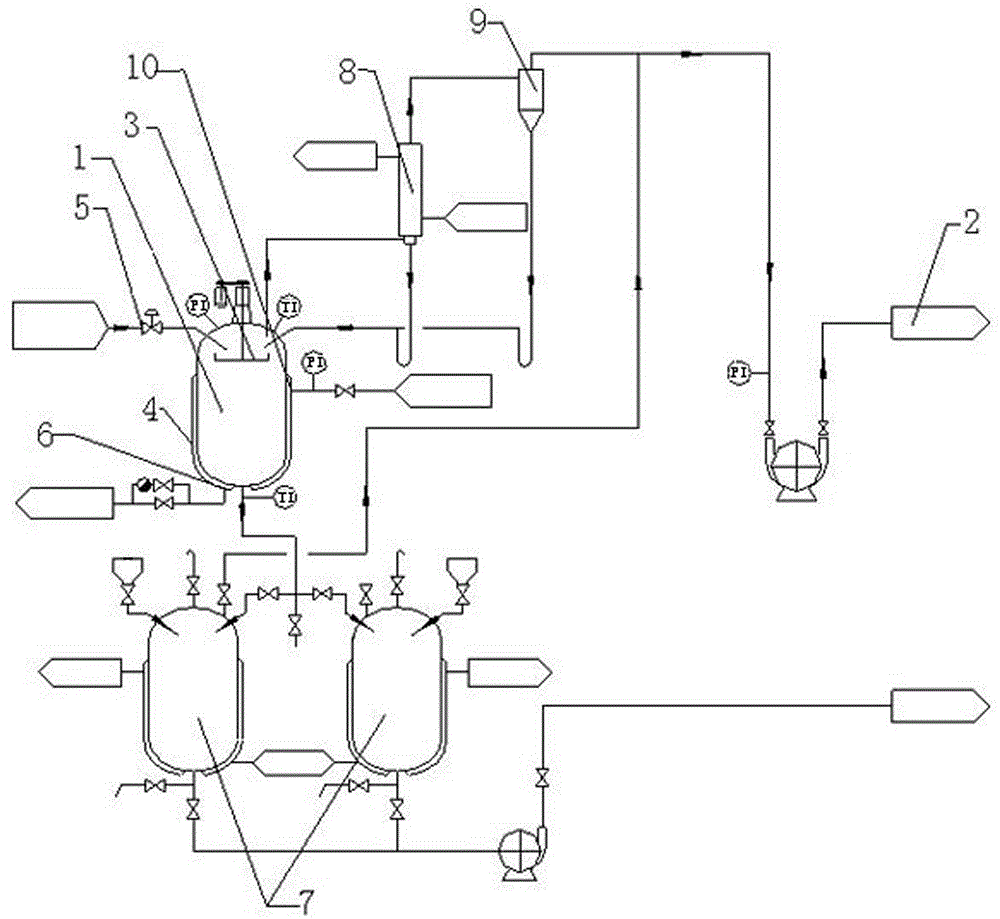

Method and device for removing hydrogen chloride and residual chlorine from liquid chlorinated paraffin

A chlorinated paraffin and dehydrochlorination technology, which is applied in liquid degassing, chemical instruments and methods, separation methods, etc., can solve problems such as unstable product quality, high energy consumption, and small output, and achieve liquid film thickness and uniformity. Continuous operation, the effect of thin liquid film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Turn on the wax oil liquid ring vacuum pump, model F2SK-2 corrosion-resistant liquid ring vacuum pump, pump the negative pressure of the degassing kettle to -0.09MPa, turn on the spinner motor, adjust the speed at 160r / min through frequency conversion, and turn on the jacket steam of the degassing kettle The valve steam pressure is controlled at 0.2MPa, open the chlorinated paraffin feed valve, control the feed rate at 2.5m3 / h, adjust the steam pressure of the degassing kettle jacket, and control the temperature of the chlorinated paraffin out of the degassing kettle between 80-90°C between. After adding the heat stabilizer ethylene glycol diglycidyl ether with a weight ratio of 3‰, the discharged chlorinated paraffin was evenly stirred. After testing, the heat loss was 0.2%, the color platinum-cobalt number was 50, and the chlorine content was 52%. . The detection indicators all meet the requirements of the HG 2092 chlorinated paraffin-52 product standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com