Gas-cap demolding pair-roller biofertilizer granulator

A granulator and bio-fertilizer technology, applied in the direction of mold extrusion granulation, etc., can solve the problems affecting the next granulation efficiency and product quality, improve granulation efficiency and granulation quality, reduce materials and granule adhesion Roller, the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

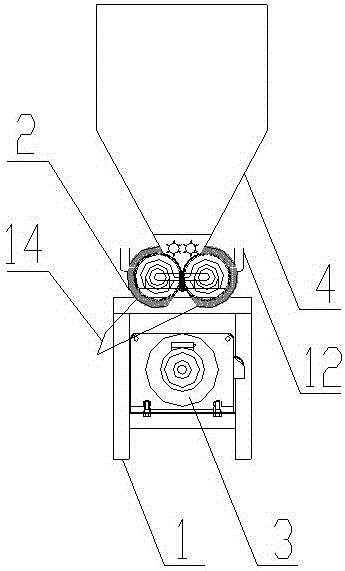

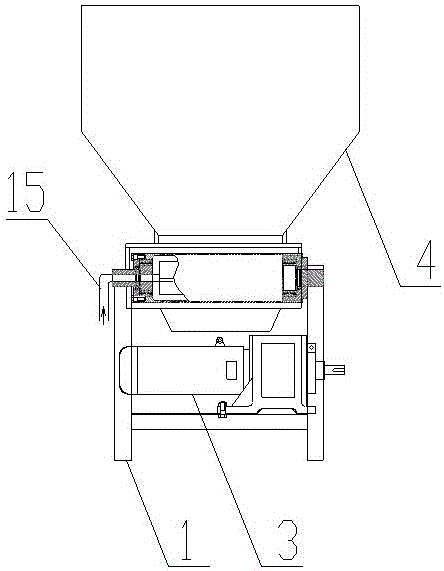

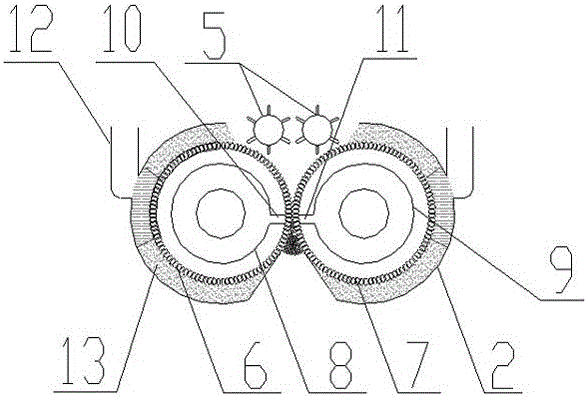

[0011] Such as Figure 1-4 As shown, the present invention includes: frame 1, granulator shell 2, motor 3, material bin 4, a pair of material booster wheels 5, A granulation roller 6, B granulation roller 7, A ventilation shaft 8, B Ventilation shaft 9, A air channel 10, B air channel 11, hydraulic oil inlet 12, felt 13 and hopper 14, the granulator shell 2 is located at the top of the frame 1, and the motor 3 is located on the frame 1 , the material bin 4 is located at the top of the granulator shell 2, the pair of material booster wheels 5 are respectively installed at the bottom of the material bin, and the A granulation roller 6 and the B granulation roller 7 are respectively located at the granulator shell 2 Inside, and arranged horizontally, the outer surfaces of the A granulation roller 6 and B granulation roller 7 are evenly distributed with a group of semi-arc grooves, and the bottom of the semi-arc grooves is provided with ventilation holes 16, and the A granulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com