Pneumatic anti-clogging cooling device of biomass particle granulator ring mold

A technology of biomass granules and cooling devices, applied in the direction of mold extrusion granulation, presses, manufacturing tools, etc., can solve problems such as ring die hole blockage, achieve the effects of prolonging life, improving working environment, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

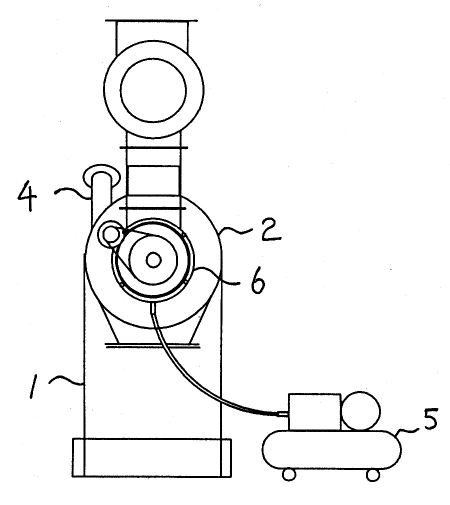

[0030] Such as figure 1 , a pneumatic anti-clogging cooling device for a ring die of a biomass granulator, which includes a forced air supply pipe 6 and an air supply branch pipe 7, the forced air supply pipe 6 is annular, and the forced air supply pipe 6 is along its axial direction A plurality of air supply branch pipes 7 communicating with the forced air supply pipe 6 are provided, and the air supply branch pipes 7 communicate with the inside of the ring die 8 of the granulator 1 .

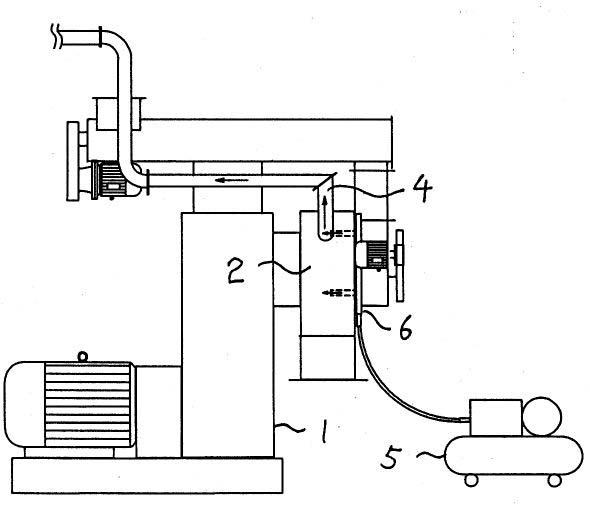

[0031] Such as figure 2 The forced air duct 6 is arranged outside the door 2 of the granulation chamber.

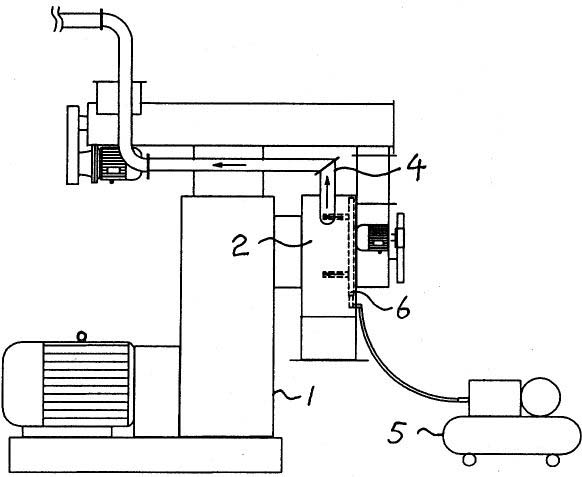

[0032] Such as image 3 , The forced air supply pipe 6 is set inside the door 2 of the granulation chamber, and the forced air supply pipe 6 is located in the granulation chamber 3 .

[0033] Such as Figure 7 , Figure 8 , when the forced air supply pipe 6 is set inside the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com