Fertilizer for tomatoes and preparation method thereof

A tomato and fertilizer technology, applied in the field of tomato fertilizer and its preparation, can solve the problems of endangering human health, deterioration of chemical fertilizer use, weak disease resistance, etc., and achieve the effects of improving disease resistance, soft soil, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

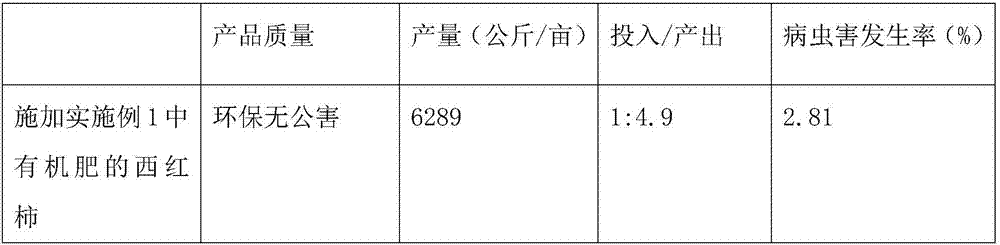

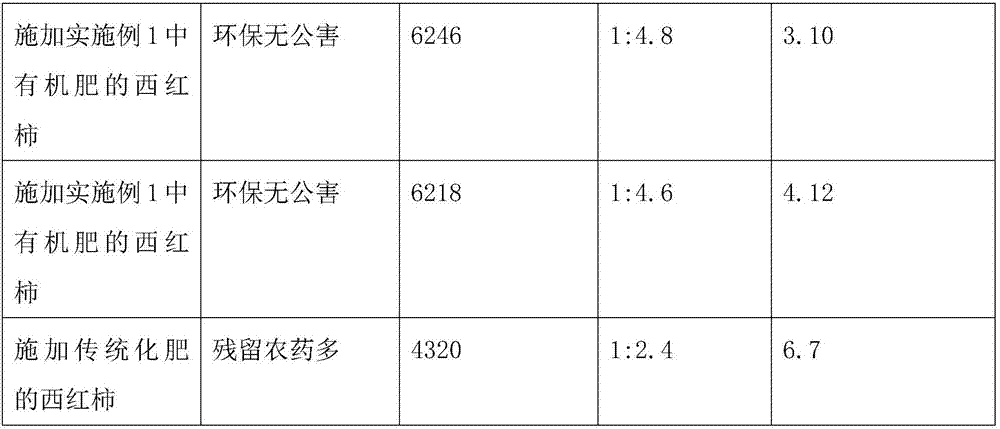

Examples

Embodiment 1

[0042] A tomato fertilizer, comprising the following raw materials in parts by weight: 95 parts of rotten fruit, 40 parts of poultry manure, 9 parts of corncobs, 10 parts of peanut shells, 12 parts of peat, 9 parts of coal gangue, 15 parts of distiller's grains, 7 parts of vermiculite powder, 10 parts of Sophora flavescens, 9 parts of peanut oil residue, 7 parts of pumpkin vine, 6 parts of medical stone, 28 parts of rice bran, 9 parts of perlite, 11 parts of diamine phosphate, 19 parts of potassium chloride, 10 parts of strain powder, 9 parts of bentonite 11 parts of pea powder, 4 parts of zeolite powder, 17 parts of attapulgite, 4 parts of humus soil, 25 parts of corn straw and 5 parts of rapeseed cake.

[0043] Corn cobs are added to the raw materials, and the corn cobs contain sugar, crude protein, crude fat, crude fiber and minerals.

[0044] Peanut shells are added to the raw materials. Peanut shells contain crude protein, fat, crude cellulose, soluble carbohydrates, calc...

Embodiment 2

[0063] A tomato fertilizer, comprising the following raw materials in parts by weight: 90 parts of rotten fruit, 30 parts of poultry manure, 8 parts of corncobs, 5 parts of peanut shells, 10 parts of peat, 5 parts of coal gangue, 10 parts of distiller's grains, 5 parts of vermiculite powder, 7 parts of Sophora flavescens, 8 parts of peanut oil residue, 6 parts of pumpkin vine, 3 parts of medical stone, 22 parts of rice bran, 7 parts of perlite, 10 parts of diamine phosphate, 18 parts of potassium chloride, 9 parts of strain powder, 6 parts of bentonite 9 parts of pea powder, 3 parts of zeolite powder, 13 parts of attapulgite, 2 parts of humus soil, 20 parts of corn straw and 2 parts of rapeseed cake.

[0064] Corn cobs are added to the raw materials, and the corn cobs contain sugar, crude protein, crude fat, crude fiber and minerals.

[0065] Peanut shells are added to the raw materials. Peanut shells contain crude protein, fat, crude cellulose, soluble carbohydrates, calcium,...

Embodiment 3

[0083] A tomato fertilizer, comprising the following raw materials in parts by weight: 100 parts of rotten fruit, 50 parts of poultry manure, 10 parts of corncobs, 15 parts of peanut shells, 14 parts of peat, 13 parts of coal gangue, 20 parts of distiller's grains, 9 parts of vermiculite powder, 13 parts of Sophora flavescens, 10 parts of peanut oil residue, 8 parts of pumpkin vine, 9 parts of medical stone, 34 parts of rice bran, 11 parts of perlite, 12 parts of diamine phosphate, 20 parts of potassium chloride, 11 parts of strain powder, 12 parts of bentonite 13 parts of pea powder, 5 parts of zeolite powder, 21 parts of attapulgite, 6 parts of humus soil, 30 parts of corn straw and 8 parts of rapeseed cake.

[0084] Corn cobs are added to the raw materials, and the corn cobs contain sugar, crude protein, crude fat, crude fiber and minerals.

[0085] Peanut shells are added to the raw materials. Peanut shells contain crude protein, fat, crude cellulose, soluble carbohydrates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com