Centrifugal spray granulation process for preparing high-density ITO target material

A centrifugal spray, high-density technology, applied in the field of ITO target material processing, can solve the problem of slow drying rate of misty raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

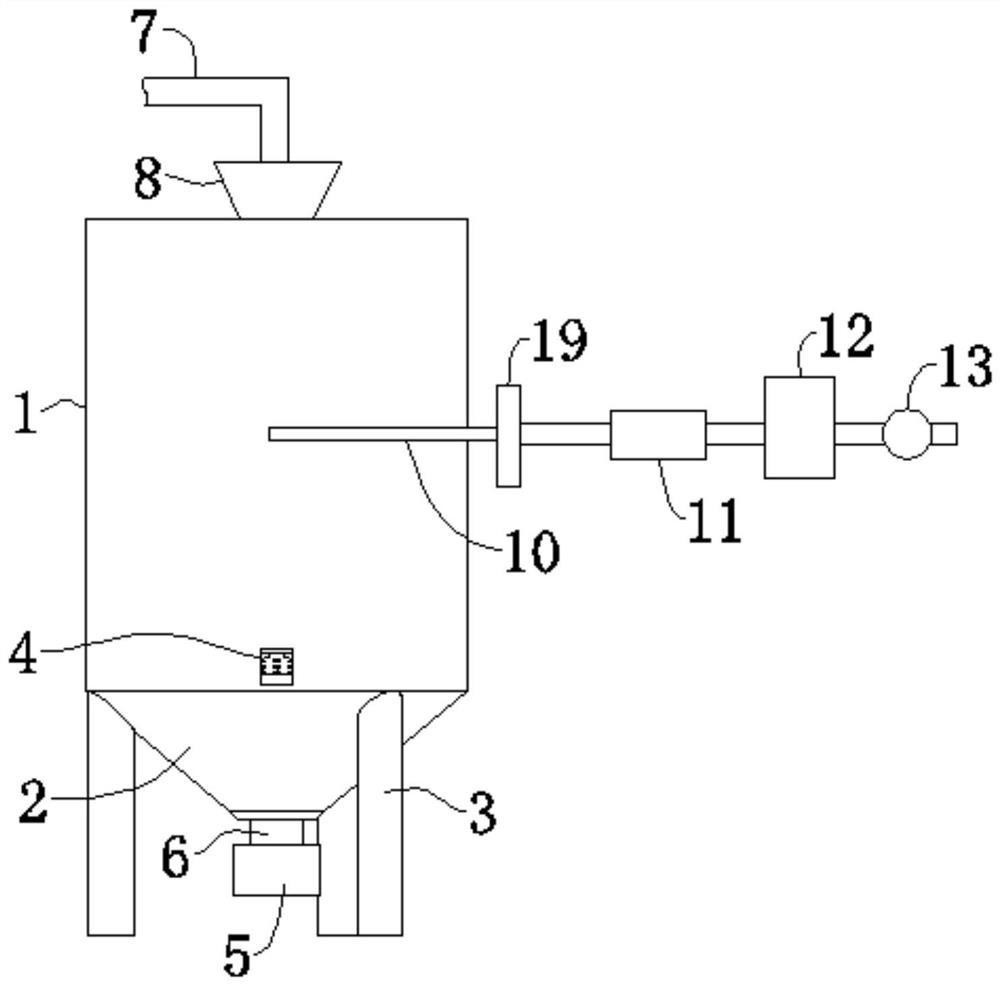

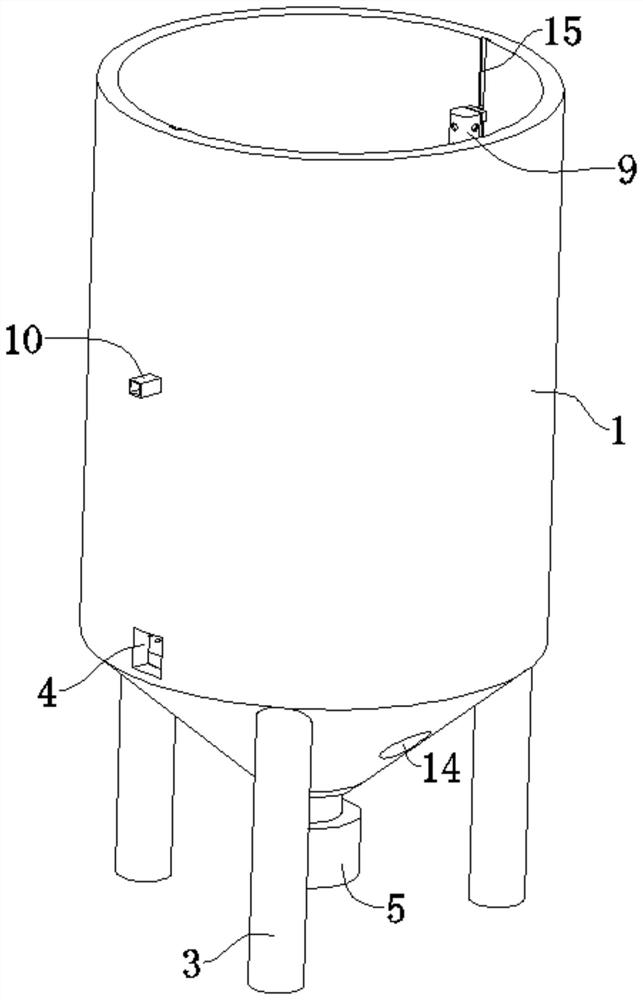

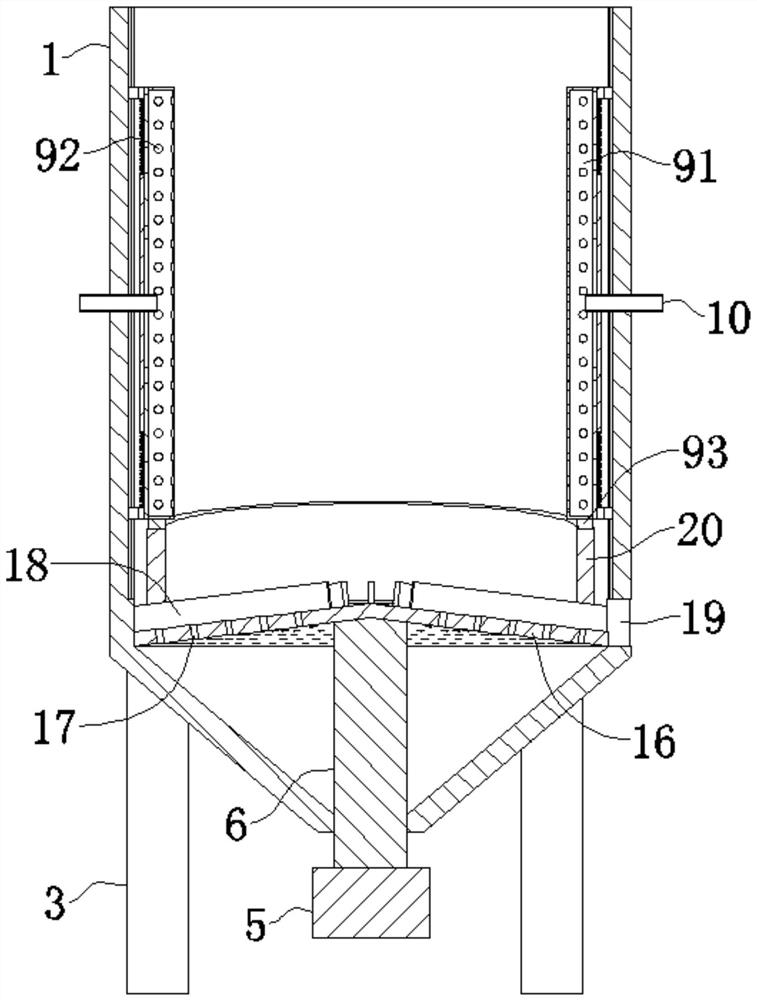

[0036] Example 1: A centrifugal spray granulation process for preparing high-density ITO targets, such as Figure 1-7 shown, including the following steps:

[0037] S1, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, and In is weighed with a purity greater than 99.99%. 2 o 3 Nanopowder and SnO 2 Nano powder, add deionized water and dispersant, stir evenly to obtain a slurry with a solid content of 65%;

[0038]S2. Mill the slurry in step S1 by a sand mill for 20 minutes, then add a binder and a defoamer, and mix evenly to obtain a slurry to be granulated;

[0039] S3, extract the outside air through the fan 13, so that the air is discharged into the tank body 1 through the air distribution pipe 9 in the tank body 1 used for granulation after passing through the filter 12, the heater 11 and the air collecting pipe 19 in sequence, until the cloth in the tank body 1 Hot gas with a full temperature of 180°C; transport the slurry to be granulated in step S2 through the f...

Embodiment 2

[0049] Embodiment 2: A centrifugal spray granulation process for preparing high-density ITO targets, the difference from Embodiment 1 is that it includes the following steps:

[0050] S1, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, and In is weighed with a purity greater than 99.99%. 2 o 3 Nanopowder and SnO 2 Nano powder, add deionized water and dispersant, stir evenly to obtain a slurry with a solid content of 60%;

[0051] S2. Mill the slurry in step S1 by a sand mill for 10 minutes, then add a binder and a defoamer, mix evenly, and obtain the slurry to be granulated;

[0052] S3, extract the outside air through the fan 13, so that the air is discharged into the tank body 1 through the air distribution pipe 9 in the tank body 1 used for granulation after passing through the filter 12, the heater 11 and the air collecting pipe 19 in sequence, until the cloth in the tank body 1 Hot gas with a full temperature of 130°C; transport the slurry to be granulated in st...

Embodiment 3

[0055] Embodiment 3: A centrifugal spray granulation process for preparing high-density ITO targets, the difference from Embodiment 1 is that it includes the following steps:

[0056] S1, according to In 2 o 3 / SnO 2 The mass ratio is 9:1, and In is weighed with a purity greater than 99.99%. 2 o 3 Nanopowder and SnO 2 Nano powder, add deionized water and dispersant, stir evenly to obtain a slurry with a solid content of 70%;

[0057] S2. Mill the slurry in step S1 by a sand mill for 30 minutes, then add a binder and a defoamer, and mix evenly to obtain a slurry to be granulated;

[0058] S3, extract the outside air through the fan 13, so that the air is discharged into the tank body 1 through the air distribution pipe 9 in the tank body 1 used for granulation after passing through the filter 12, the heater 11 and the air collecting pipe 19 in sequence, until the cloth in the tank body 1 Hot gas with a full temperature of 240°C; transport the slurry to be granulated in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com