Control method of ABC dry powder grain size distribution content

A technology of dry powder fire extinguishing agent and particle size distribution, which is applied in fire prevention equipment, phosphorus oxyacid, granulation in rotating disk/pot, etc., which can solve the problem of increasing production costs, fire extinguishing agent can't play a role in extinguishing fire, and fire extinguishing efficiency can't meet the requirements and other issues, to achieve the effect of improving fire extinguishing efficiency, saving raw material costs, and eliminating human operation factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

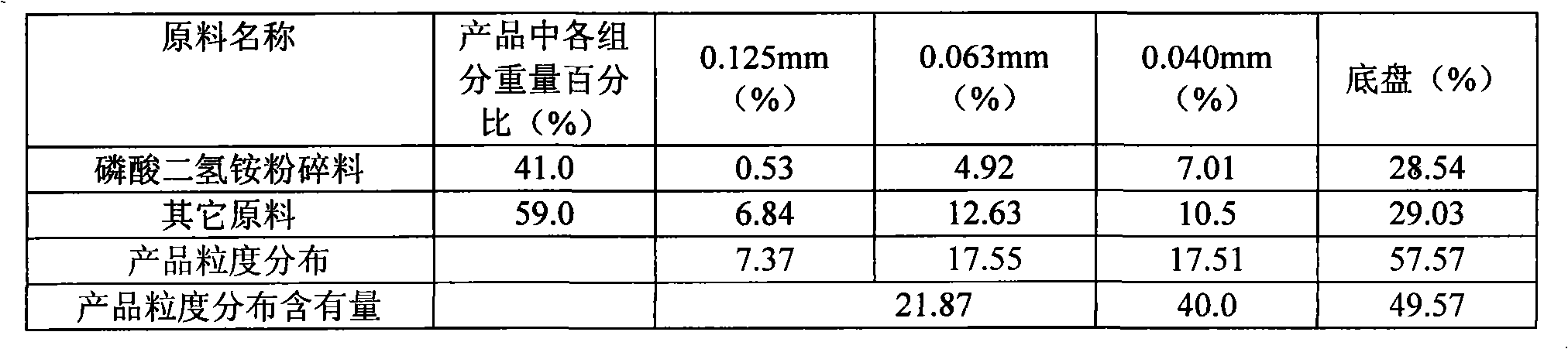

[0021] 40% ABC dry powder fire extinguishing agent, product particle size distribution "content" control method

[0022] (1) "Particle size distribution" control of ammonium dihydrogen phosphate pulverized material: a built-in graded ultrafine pulverizer is adopted, the host is continuously variable, and the classifier and feeder adopt electromagnetic variable speed. The frequency of the host is 50Hz, and the speed of the classifier is 200r / min, feeder speed 1000r / min, first crush the ammonium dihydrogen phosphate raw material, and then test the "particle size distribution" of the ammonium dihydrogen phosphate crushed material according to the national standard GB4066.1-2004 article 5.7, the test results are: in 0.125 1.3% in mm standard sieve; 12.0% in 0.063mm standard sieve; 17.1% in 0.040mm standard sieve; 69.6% in chassis, see Table 1.

[0023] (2) Selection of other raw materials and control of "particle size distribution": choose hydrophobic white carbon black, mica pow...

Embodiment 2

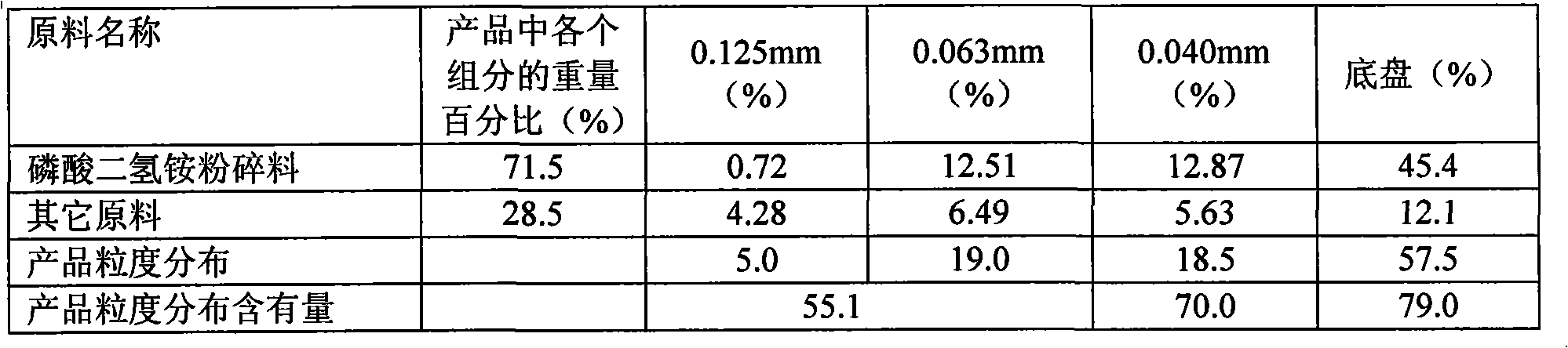

[0047] 70% ABC dry powder fire extinguishing agent, control method of product particle size distribution "content"

[0048] (1) "Particle size distribution" control of ammonium dihydrogen phosphate pulverized material: a built-in graded ultrafine pulverizer is adopted, the host is continuously variable, and the classifier and feeder adopt electromagnetic variable speed, according to the host frequency 48Hz, classifier speed 250r / Min, the speed of the feeder is 900r / min, first crush the ammonium dihydrogen phosphate raw material, and then test the particle size distribution of the crushed ammonium dihydrogen phosphate according to the national standard GB4066.1-2004 article 5.7; the test results are: 1.0% in the middle; 17.5% in the 0.063mm standard sieve; 18.0% in the 0.040mm standard sieve; 63.5% in the chassis, see Table 3.

[0049] (2) Other raw material selection and particle size distribution control: choose hydrophobic white carbon black, mica powder, activated clay, an...

Embodiment 3

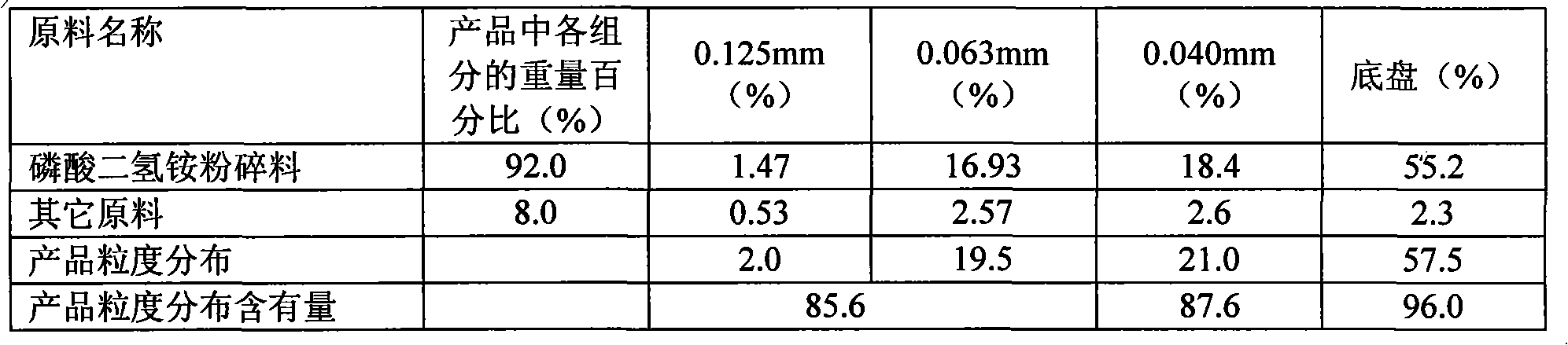

[0056] 90% ABC dry powder fire extinguishing agent, control method of product particle size distribution "content"

[0057] (1) "Particle size distribution" control of ammonium dihydrogen phosphate pulverized material: a built-in graded ultrafine pulverizer is adopted, the host is continuously variable, and the classifier and feeder adopt electromagnetic variable speed. The frequency of the host is 45Hz, and the speed of the classifier is 300r / min, feeder speed 800r / min, first crush the ammonium dihydrogen phosphate raw material, and then test the particle size distribution of the crushed ammonium dihydrogen phosphate. The test results are: 1.6% in 0.125mm standard sieve; 18.4% in 0.063mm standard sieve;

[0058] 20.0% in the standard sieve; 60.0% in the chassis, see Table 5.

[0059] (2) Selection of other raw materials and control of "particle size distribution": choose hydrophobic white carbon black, mica powder, activated clay, and talcum powder as auxiliary filling mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com