Spherical powder and its preparation

A powder and spherical technology, which is applied in the field of spherical powder and its preparation, can solve problems such as insufficient strength of tungsten carbide alloys, and achieve the effects of uniform composition and structure, reduced heat loss, and increased grain yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

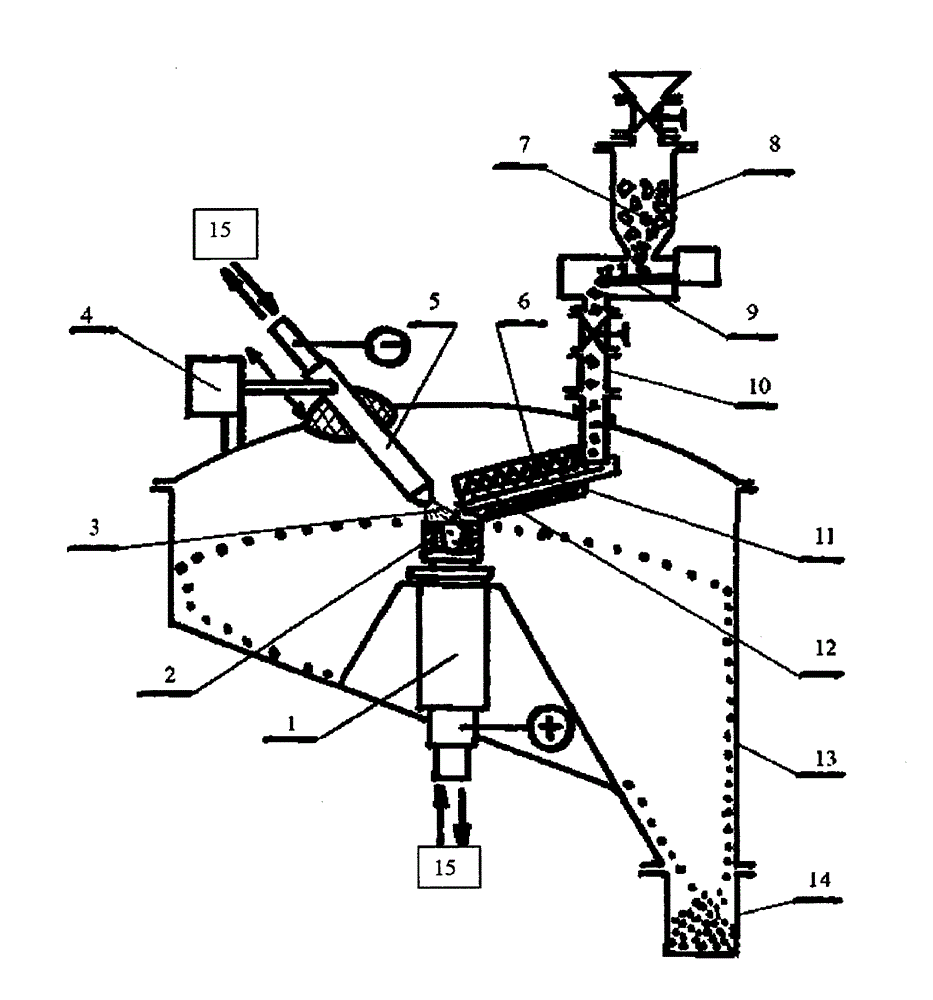

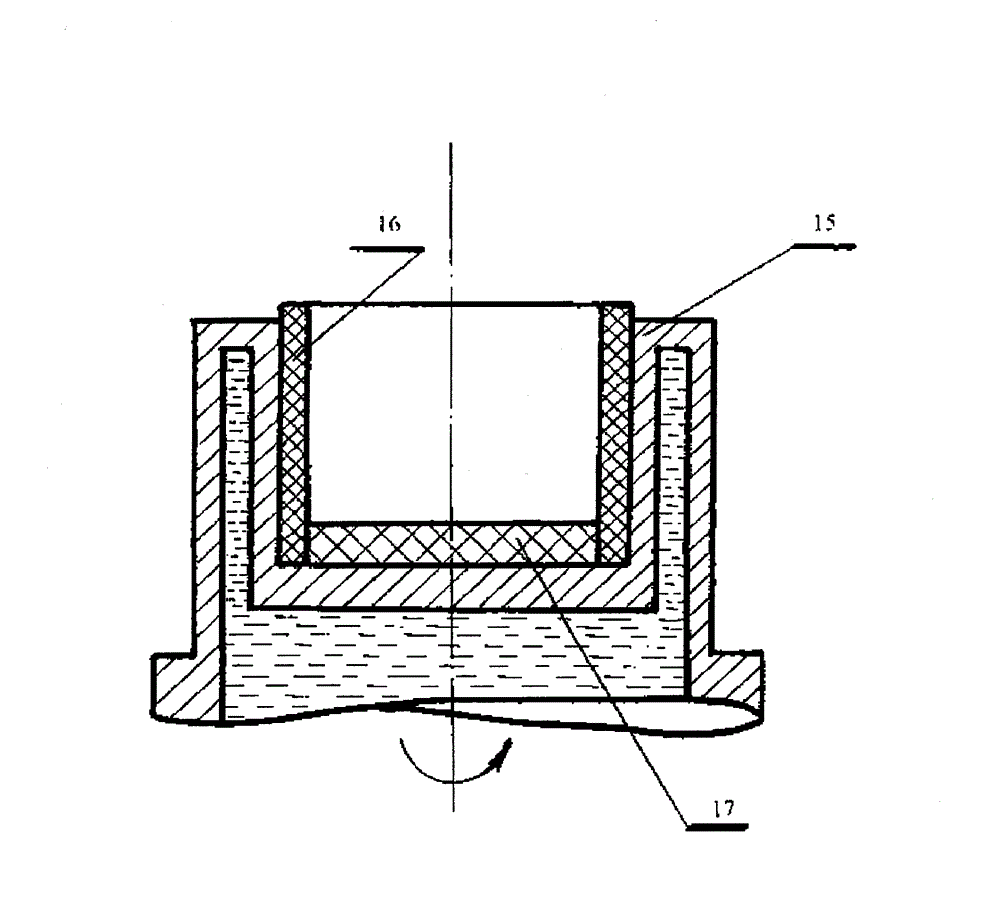

Method used

Image

Examples

example 1

[0077] Tungsten with a melting point of 3380° C. was atomized on a centrifugal atomization device equipped and not equipped with the device of the invention described herein. Nebulization was performed under pure nitrogen atmosphere. Crucibles were used with and without the lining according to the invention. The diameter of the opening edge of the crucible is 60mm. The rotation speed of the crucible was 5000 rpm. The current of the plasma arc alternates within the limits of 800 to 1500A, and the arc voltage is 70 to 85V. The gravel is preheated by bringing the moving raw gravel into contact with the face of a tungsten trough surrounded by tubular heaters. The heater is made of carbon-carbon composite material, and the heater is heated to 2500°C by passing electric current from an automatic power supply. The outlet temperature of the grit flowing out of the heater is 1850-1950°C. The atomization results are shown in Table 1. Using the method to atomize tungsten on the dev...

example 2

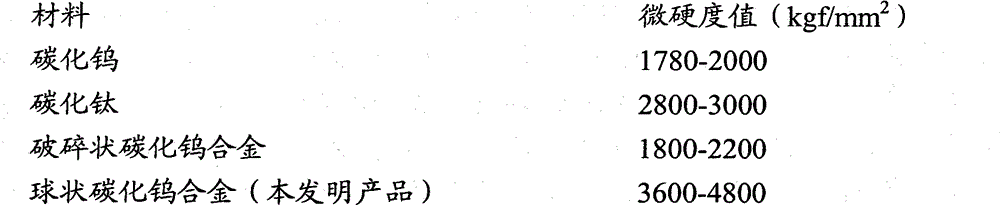

[0081] Sintered tungsten carbide (tungsten carbide eutectic mixture WC-W 2 C) Nebulize. Crushed sintered tungsten carbide grit with a particle size of less than 1 mm is used for atomization. The carbon content in the original gravel is 4.0% of its mass, and the average microhardness of crushed and sintered tungsten carbide is Hμ-1800HV. The current of the plasma arc alternates within the limits of 800 to 1500A, and the arc voltage is 70 to 85V. Cemented tungsten carbide grit is preheated by bringing moving raw grit into contact with the inner surface of a tubular heater. The heater is made of carbon-carbon composite material, and the heater is heated to 2200°C by passing electric current from an automatic power supply. The outlet temperature of the grit flowing out of the heater is 1850-1900°C. Atomization was performed in a pure nitrogen atmosphere using a crucible with an open edge diameter of 62 mm. A comparative atomization of cemented tungsten carbide grit was also c...

example 3

[0085] Example 3 (comparison)

[0086] The particle size range of the prepared powder is 50 to 800 microns. The microhardness of the molten tungsten carbide powder produced by the method is 3400-3550kgf / mm 2 In the range. This is 1.25-1.27 times the microhardness value of tungsten carbide powder produced in an argon atmosphere. The increase of microhardness significantly enhances the wear resistance of the material.

[0087] The apparent density of the obtained powder is 8.5-10.0g / cm 3 In the range of , this apparent density value indirectly indicates its internal porosity and deviation from a perfect sphere.

[0088] Using high currents slightly improves the hardness and strength properties of the product. However, due to the impact of high-intensity current, the electrodes are easily damaged, and the electrodes must be replaced frequently. In addition, the edges of the crucible are severely worn when high currents are used. This causes instability in the atomization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com