Extrusion-spheronization integrated granulating machine

An extrusion spheronization and integrated technology, which is applied in the field of extrusion spheronization integrated granulator, can solve the problems of inconsistent particle size, easy loose compressive strength, and large use space, so as to shorten the granulation time and improve the production efficiency. The effect of particles and the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

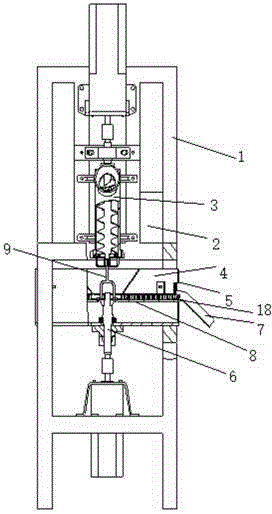

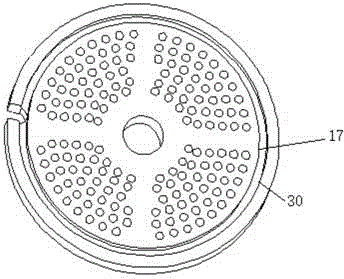

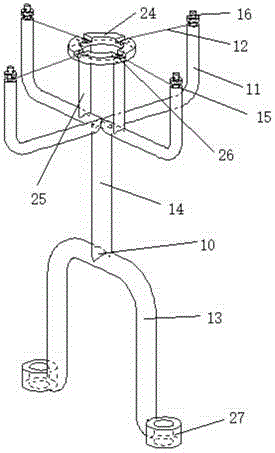

[0025] The structure of the extruding and spheronizing integrated granulator provided by the present invention is as follows: figure 1 As shown, the granulator at least includes a frame 1, an electrical control system 2, a screw extruder 3 and a spheronizer 4, the screw extruder 3 and the spheronizer 4 are fixed on the frame 1, the screw extruder 3 and the spheronizer 4 The spheronizer 4 is controlled by the electric control system 2 . The spheronizer 4 comprises a rounding barrel 5, a bottom rotating shaft 6, a discharge port 7 and a rounding disc 8, and the bottom rotating shaft 7 is installed on the shaft hole of the rounding disc 8 by the bearing on the rounding barrel 5. A bracket cutter mechanism 9 is arranged between the screw extruder 3 and the spheronizer 4 . The support knife-cutting structure 9 at least comprises a base support 10, two U-shaped filament ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com