Method for inhibiting generation of large pellets and suitable for being used in disk pelletizer

A technology of large pellets and pelletizers, applied in the direction of granulation in the rotating disk/pot, etc., can solve the problem that unqualified large pellets appear in a position in the disk, and sometimes unqualified large pellets appear In another position of the disc, etc., to avoid mis-breaking, high safety, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A method for producing large suppressed pellets suitable for a disc pelletizer is to use a large suppressed pellet generating device set near the disc of the pelletizer to crush unqualified large pellets. According to the actual position of the unqualified large pellets generated in the pelletizing machine disc, by adjusting the position of the restraining rod device of the restraining large pellet generating device, the restraining rod device can be blocked in the pelletizing machine. At the lower half of the disc and at the position facing the unqualified large pellets, the unqualified large pellets are driven by the rotating pelletizer disc to hit the restraining rod device, and the unqualified pellets The big pellets shattered.

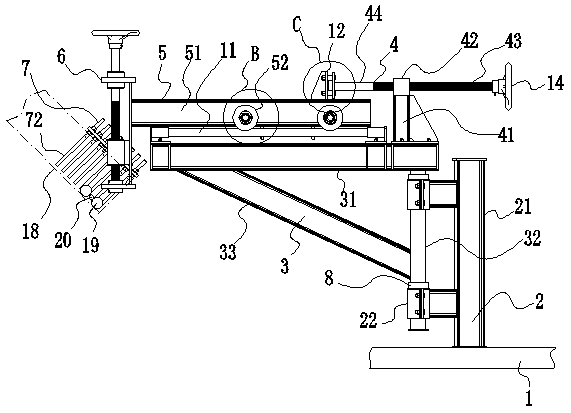

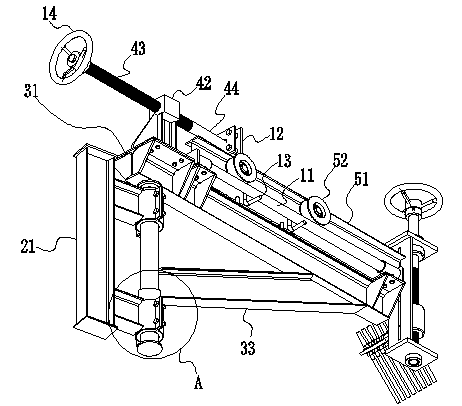

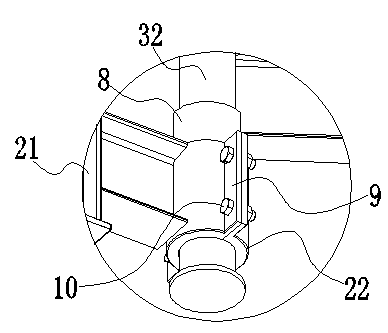

[0036] Such as figure 1 As shown, the device for suppressing large pellet generation includes a control platform 1; a support frame 2, which is fixedly arranged on the control platform 1; a trolley support 3, which is rotatably conn...

Embodiment 2

[0044] Example 2: Such as Picture 10 with Picture 11 As shown, compared with Embodiment 1, the difference is: when the lateral movement control mechanism is a hydraulic transmission mechanism or a pneumatic transmission mechanism, it includes a cylinder support block 23, which is arranged on the horizontal support plate 31 The transverse cylinder or transverse hydraulic cylinder 24, which is fixedly arranged on the cylinder support block 23; the connecting part 12 on one end of the trolley body is connected to the longitudinal cylinder body fixedly arranged on one end of the trolley body 51 The longitudinal cylinder connecting block is fixedly connected with the piston of the transverse cylinder or the transverse hydraulic cylinder 24. The trolley 5 is driven to slide back and forth along the guide rail 11 by the transverse cylinder or the transverse hydraulic cylinder 24.

[0045] The longitudinal lifting control mechanism is a hydraulic transmission mechanism or a pneumatic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com