Rotary fixing support

A fixed bracket and rotating technology, which is applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of falling off, not being able to be used in combination, and the structure of the fixed bracket needs to be improved, so as to achieve a strong ability to withstand shock and vibration , the effect of average force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

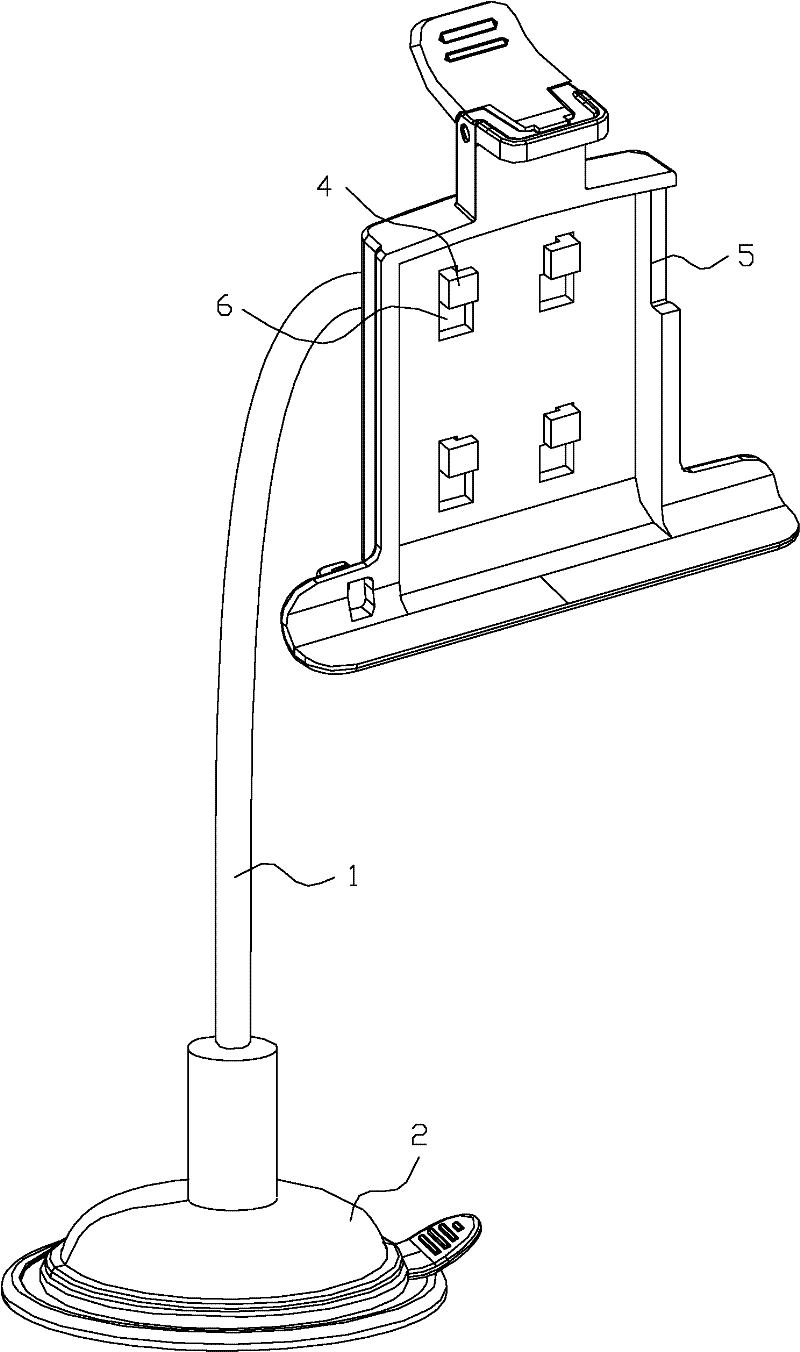

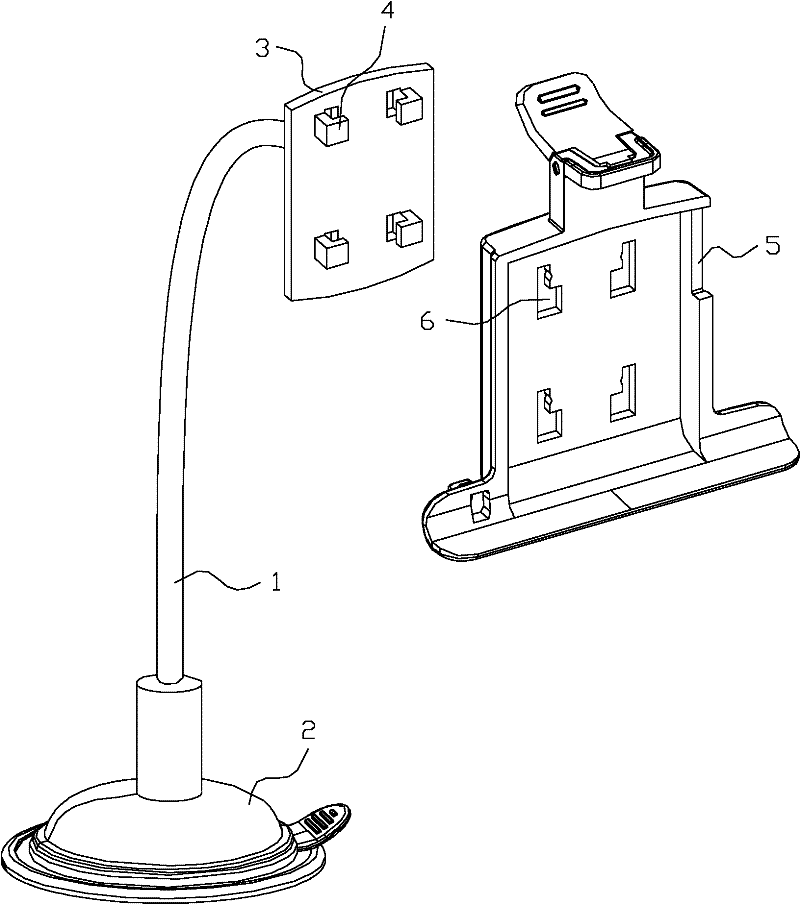

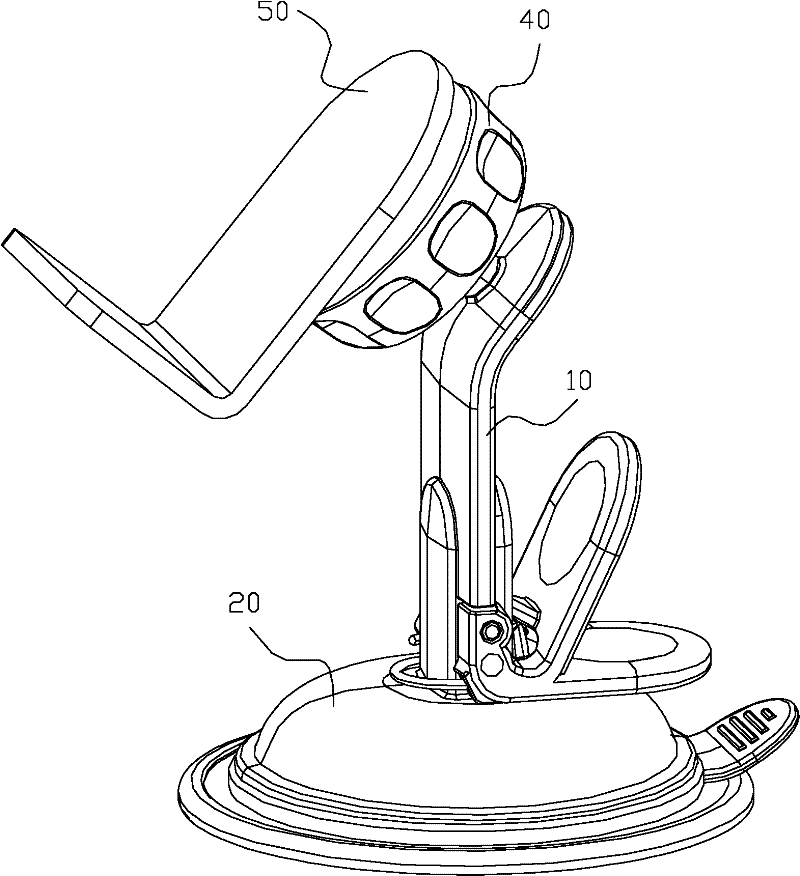

[0047] see Figure 5 to Figure 8, the first embodiment of the rotating fixed bracket of the present invention includes a threaded base 100 , a connecting plate 300 and a snap-on receiving frame 500 for placing GPS. The bottom of the threaded base 100 is provided with a mounting portion 200, and the top of the threaded base 100 is extended with a spherical body 110; the connecting plate 300 is provided with three hooks 400, and one end of the hooks 400 is provided with an elastic locking point 401, the connecting plate 300 is provided with a ring-shaped carfalcon 810 corresponding to the spherical body 110, the ring-shaped carrion 810 is used to engage the spherical body 110, the outer side of the ring-shaped carrion 810 surrounds the ring-shaped carrion 810 and is connected with An annular first fixing part 800 is provided at a distance from the ring-shaped carfalcon 810, and a thread 801 is provided on the outside of the first fixing part 800. A second fixing part 900 is slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com