Glass edge grinding machine

A kind of edge grinding machine and glass technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding the edge of workpieces, which can solve the problems of grinding fineness, low efficiency, time-consuming and labor-intensive, etc. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

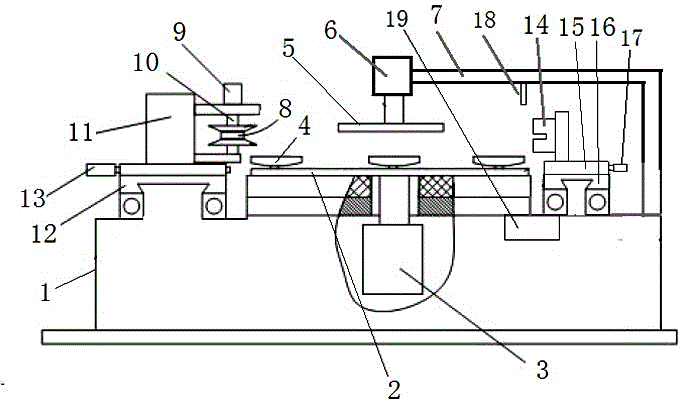

[0022] figure 1 In the embodiment, a seat body 12 is installed on the frame, and the tool holder is slidably connected to the seat body 12. At the same time, the output shaft end of the tool holder driving motor is connected with a screw rod, which is threadedly connected to the tool holder, so that the tool holder driving motor During operation, the rotation of its output shaft can drive the tool holder to move.

[0023] The debris cleaning mechanism also includes a debris cleaning mechanism base 16. The cleaning mechanism bracket 15 is slidably connected to the base 16, and the output shaft end of the sliding drive motor is connected to a screw rod. The screw thread is connected to the cleaning mechanism bracket 15, both of which can make sliding drive When the motor 17 is running, the rotation of its output shaft can drive the cleaning mechanism bracket 15 to slide.

[0024] figure 1 The embodiment also includes a water nozzle 18 and a water pipe. The pressure plate driving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com