Skidproof structure for container

a container and skid-proof technology, applied in the field of skid-proof structures for containers, can solve the problems of difficulty in picking up containers, damage to tables, and the skid-proof member may even separate with the container, and achieve the effect of reducing the contact area and adhesion force between the skid-proof member and the table surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

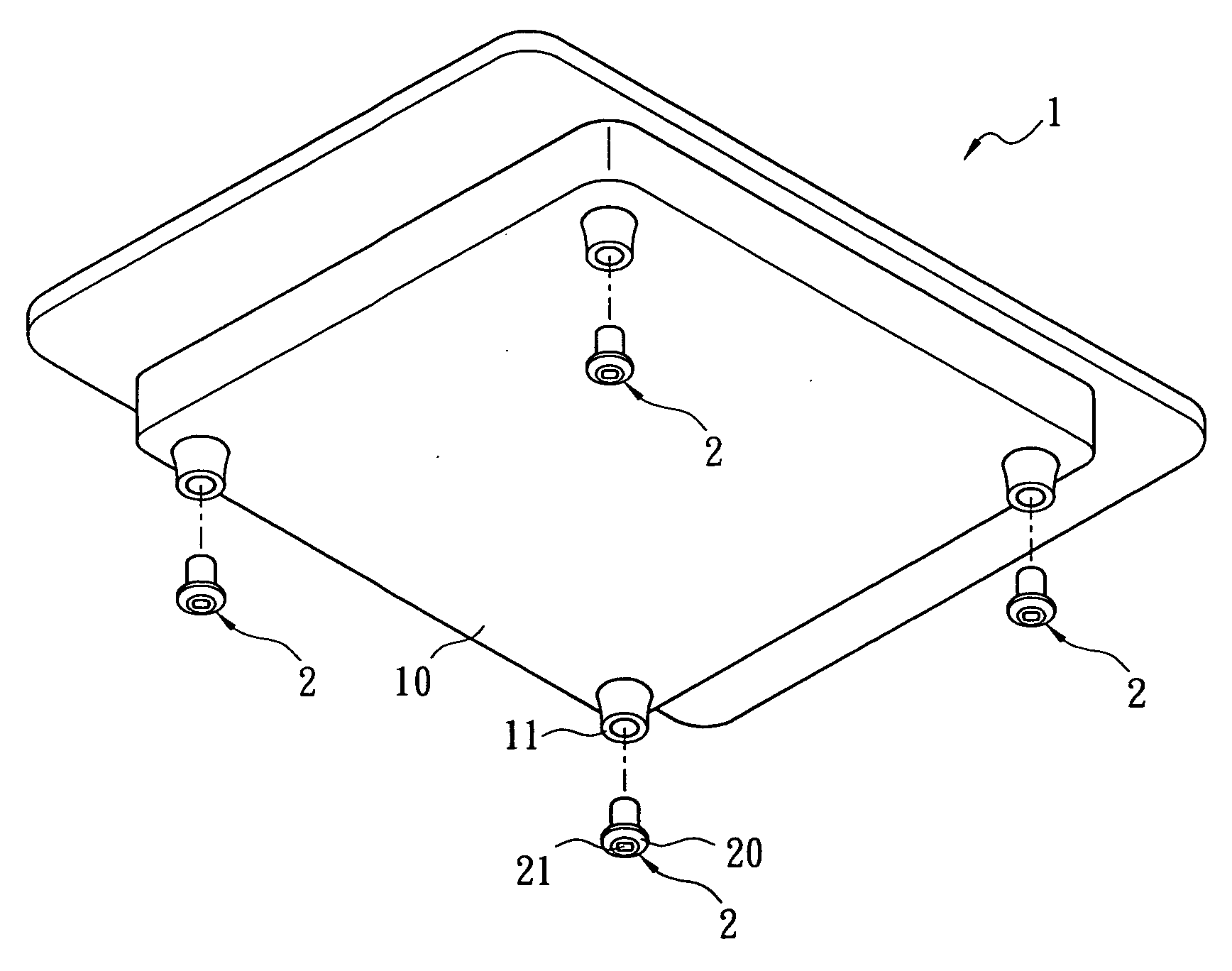

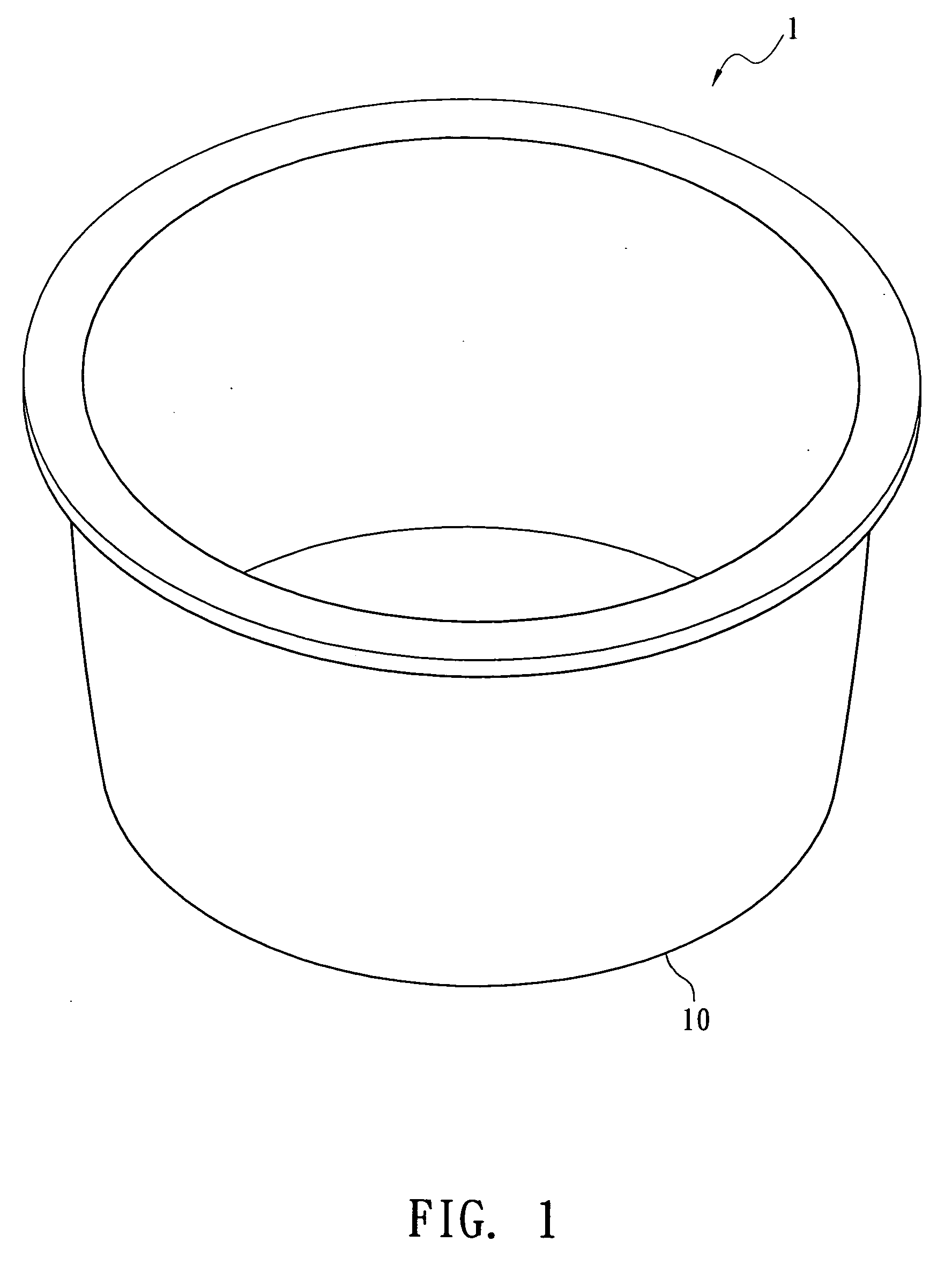

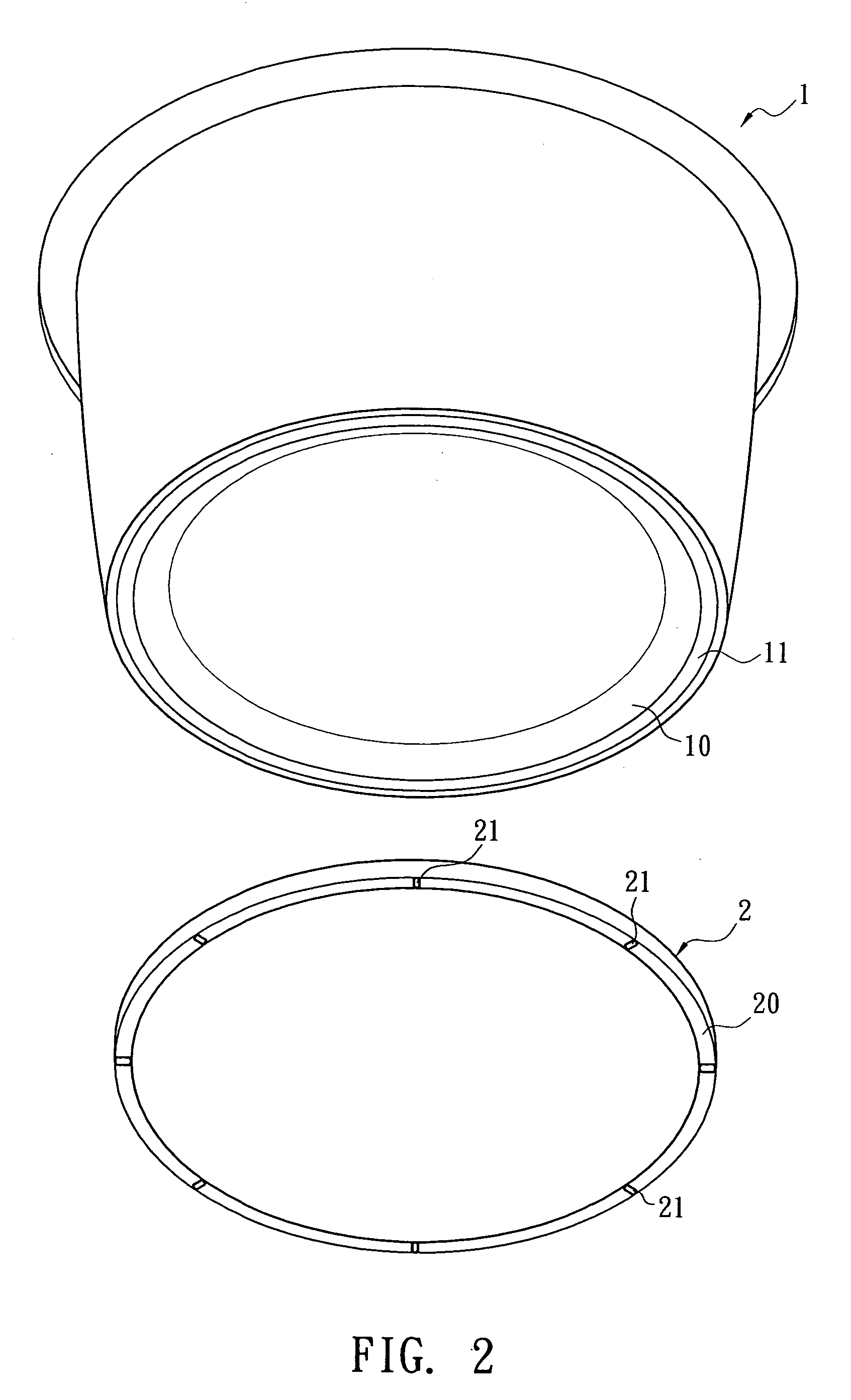

[0019]Refer from FIG. 1 to FIG. 5, a container (or utensil) 1 according to the present invention includes bowls, cups, dishes, pots or barrels. There is no limitation on material of the container 1, it can be plastic, resin, ceramic, metal or combinations of above materials while melamine with good thermal stability and luster is preferable. Moreover, there is not limitation on appearance of the container 1 or shape of the bottom 10. For example, the container 1 may have a round opening and a round bottom, as shown in FIG. 1, or have an oval opening, a rectangular opening in combination with a rectangular bottom, as shown in FIG. 6. The openings and the bottom can be irregular shapes. In order to offer ideal skidproof protection while being put on the table, at least a slot 11 is arranged on the bottom 10 of the container 1 while there is no limitation on the shape and number of the slot 11. It can be circular, as shown in FIG. 2, FIG. 7&FIG. 11, like a bar, as shown in FIG. 9&FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com