Grating and preparation method thereof

A grid and temperature control technology, applied in the field of grid processing, can solve the problems of affecting product quality, high demoulding force, high defective rate, and achieve the effect of flexible and diverse sizes, easy cutting, and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the grid is as follows:

[0025] (A) Put the raw materials for preparing the grid into the mold and then press it with the mold, the mold includes an upper mold and a lower mold;

[0026] (B) Perform compression molding, the surface temperature of the upper mold is controlled at 135°C, the temperature of the lower mold surface is controlled at 140°C, the pressure is controlled at 10MPa, and the pressure holding operation time is 600s;

[0027] (C) The product after compression molding is opened and taken out, and the upper and lower surfaces are polished to obtain a grid. The depth of the square holes of the resulting grid is 25 mm.

Embodiment 2

[0029] The preparation method of the grid is as follows:

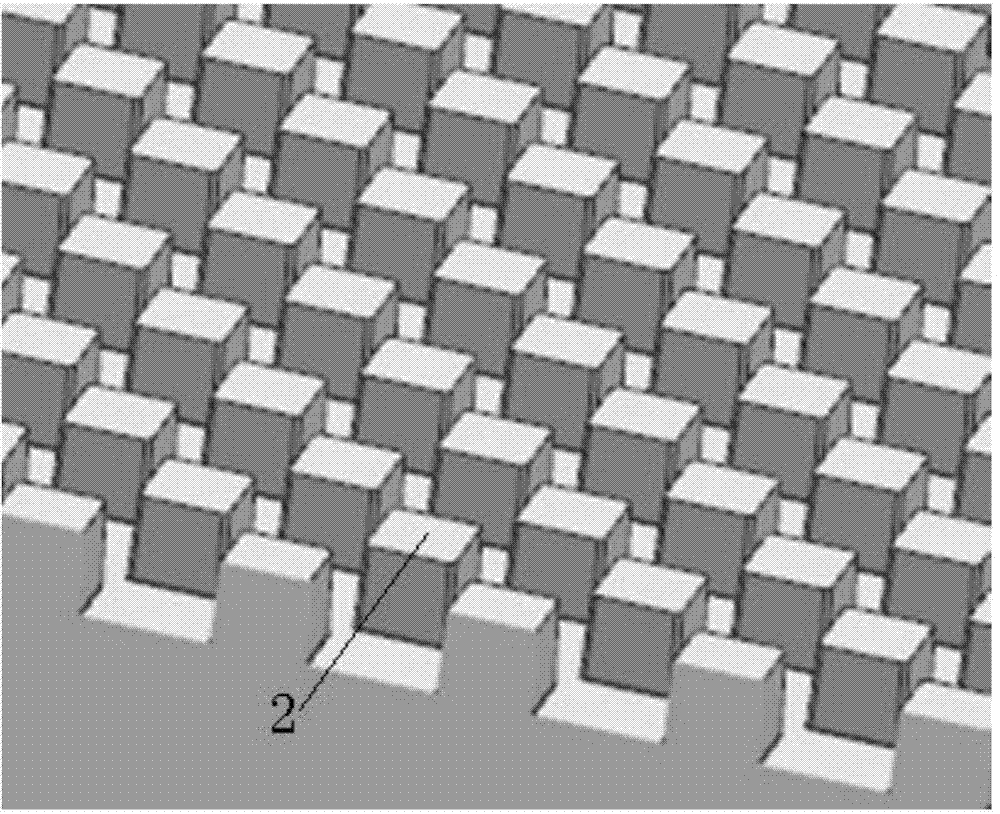

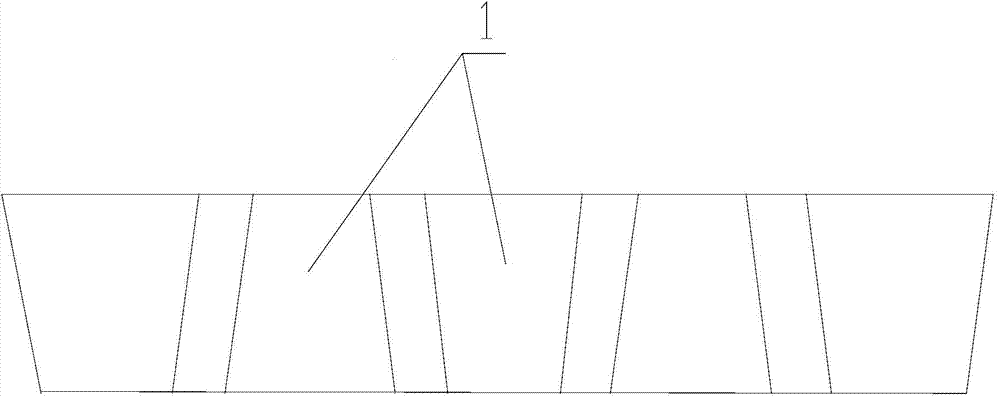

[0030] (A) Put the SMC glass fiber composite material, which is the raw material of the grid, into the mold and press it with the mold. For the specific shape of the mold, see figure 1 , Including the upper mold and the lower mold, the upper mold and the lower mold of the mold have a plurality of protrusions 2 arranged in an orderly manner. The protrusions 2 are trapezoidal. The protrusions 2 extend from the side close to the mold to the one far away from the mold. The cross-sectional area of one side gradually decreases;

[0031] (B) Compression molding is performed, the surface temperature of the upper mold is controlled at 145°C, the temperature of the lower mold surface is controlled at 150°C, the pressure is controlled at 15MPa, and the pressure holding operation time is 600s;

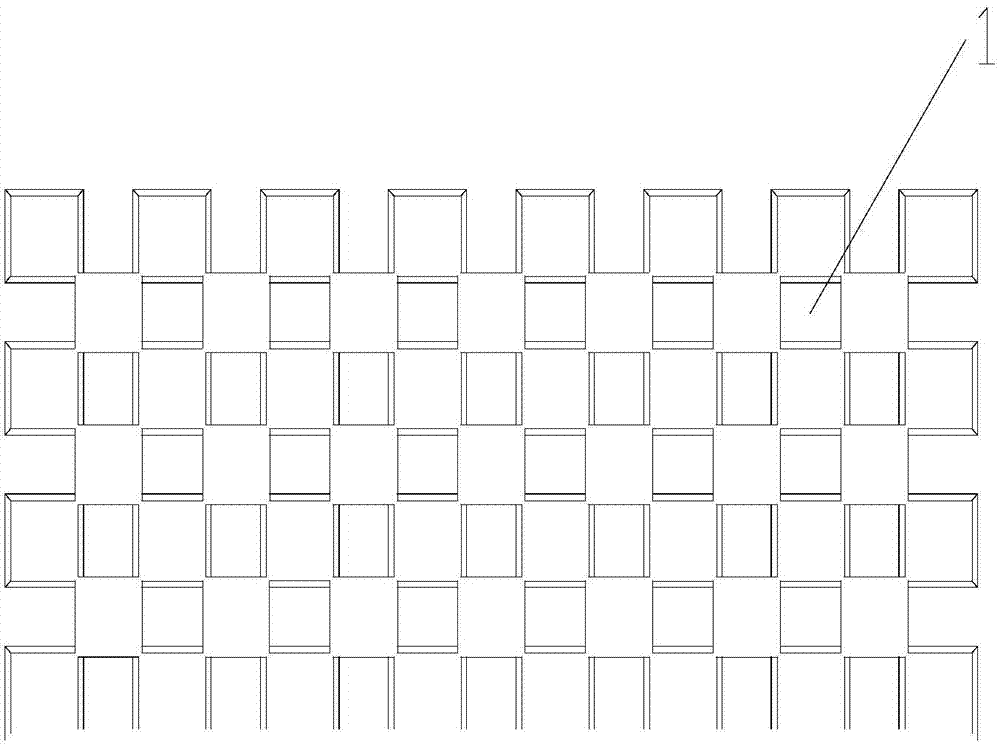

[0032] (C) Open the mold and take out the product after compression molding, and polish the upper and lower surfaces to make a grid. For the s...

Embodiment 3

[0035] The preparation method of the grid is as follows:

[0036] (A) Put the SMC glass fiber composite material, which is the raw material of the grid, into the mold and press it with the mold. The mold includes an upper mold and a lower mold. The upper mold and the lower mold of the mold have a plurality of ordered protrusions. 2. The protrusion 2 is in the shape of a trapezoid, and the cross-sectional area of the protrusion 2 gradually decreases from the side close to the mold to the side away from the mold;

[0037] (B) Press molding, the upper mold surface temperature is controlled at 140°C, the lower mold surface temperature is controlled at 145°C, the pressure is controlled at 15MPa, and the pressure holding operation time is 500s;

[0038] (C) The product after compression molding is opened and taken out, and the upper and lower surfaces are polished to obtain a grid. The specific shape of the grid includes a substrate. The substrate is provided with a plurality of square h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com