Air energy reduction method and apparatus using waste heat from condensers or other low grade heat

a waste heat and air energy technology, applied in the field of air energy reduction methods and equipment using waste heat from condensers or other low grade heat, can solve the problems of requiring dedicated thermal input, accompanied by heat increase, and achieve the effect of reducing relative humidity, increasing moisture removal efficiency, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

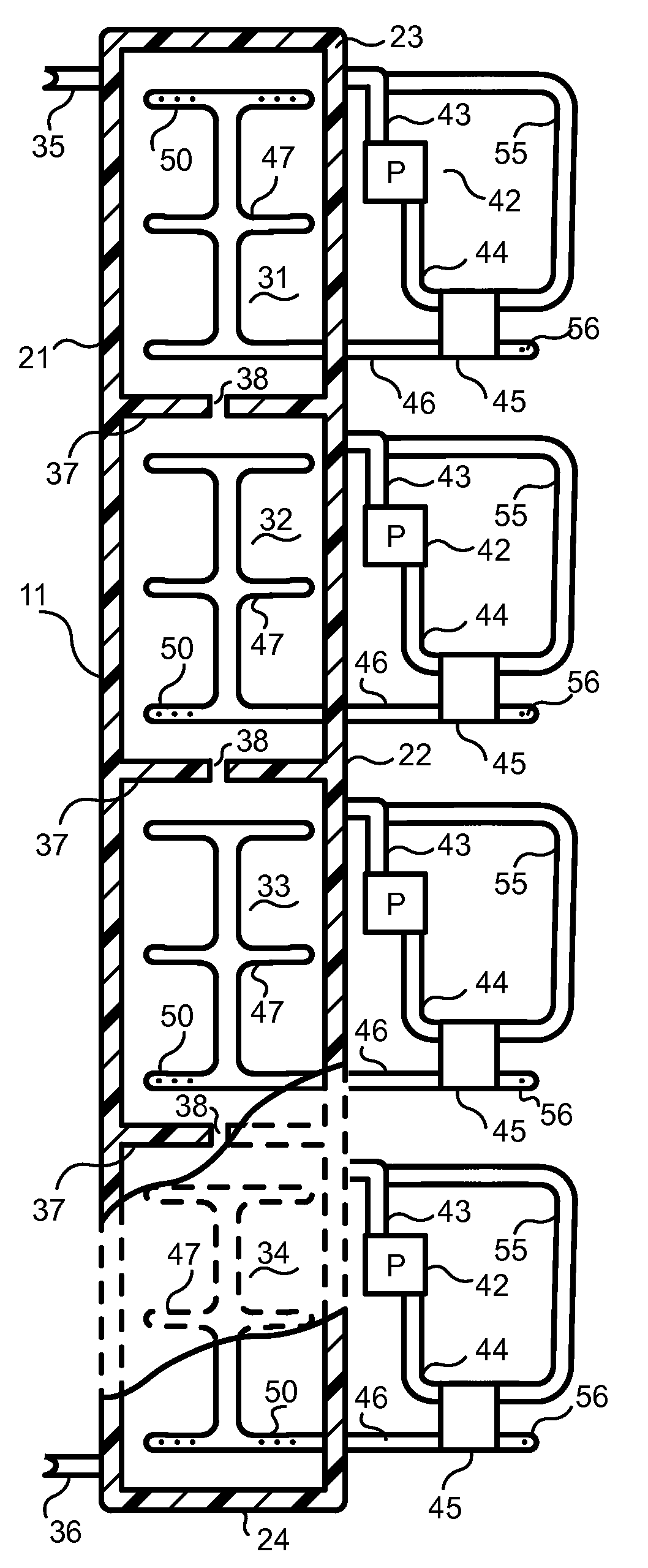

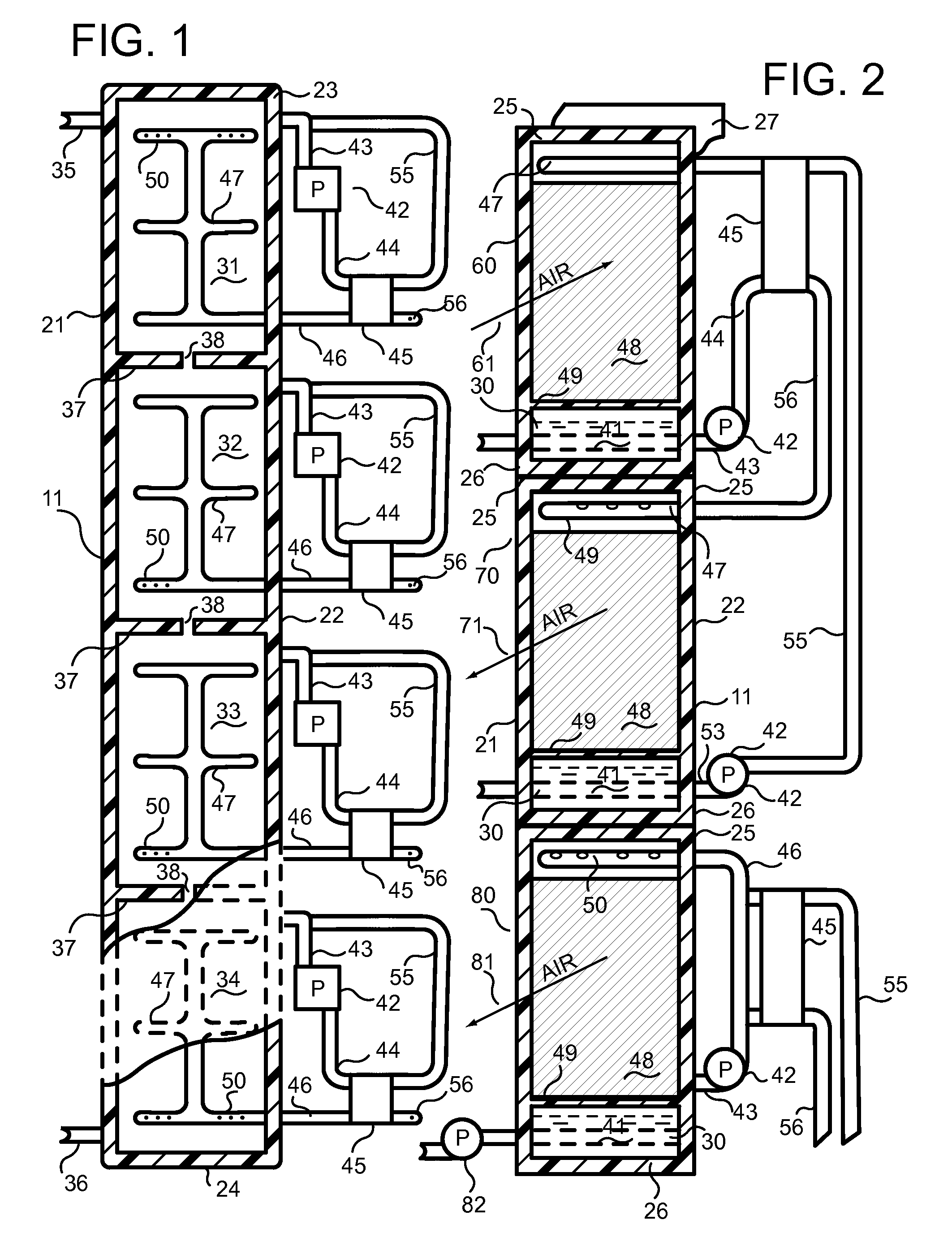

[0012]The apparatus for implementing the invention consists of a staged regenerator for removing moisture from a liquid desiccant, a staged air dehumidifier and cooler removing moisture from an air stream, and a staged saturator that maintains an air stream in a near saturated condition while exchanging heat with the dehumidifier and cooler. These three modules are generally placed in a horizontal position and they may be stacked one on the other or they may be physically separated from each other as long as they are thermally connected thermally or by means of a flow of desiccant. Each module consists of a number of stages with each stage consisting of wetting media, dedicated basin, pump and access to a liquid flow. The stages in two of the modules are thermally connected by liquid-to-liquid heat exchangers and two modules are connected by desiccant flow. Each module contains an air movement means that allows a supply of air that is separate from the other modules wherein the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com