Direct-action power generation system with speedup spring forced vibration

A technology of power generation system and forced vibration, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of fixed frequency and narrow working dynamic range of the engine, and achieve the reduction of coil weight, increase of volume capacity, and increase of coil intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

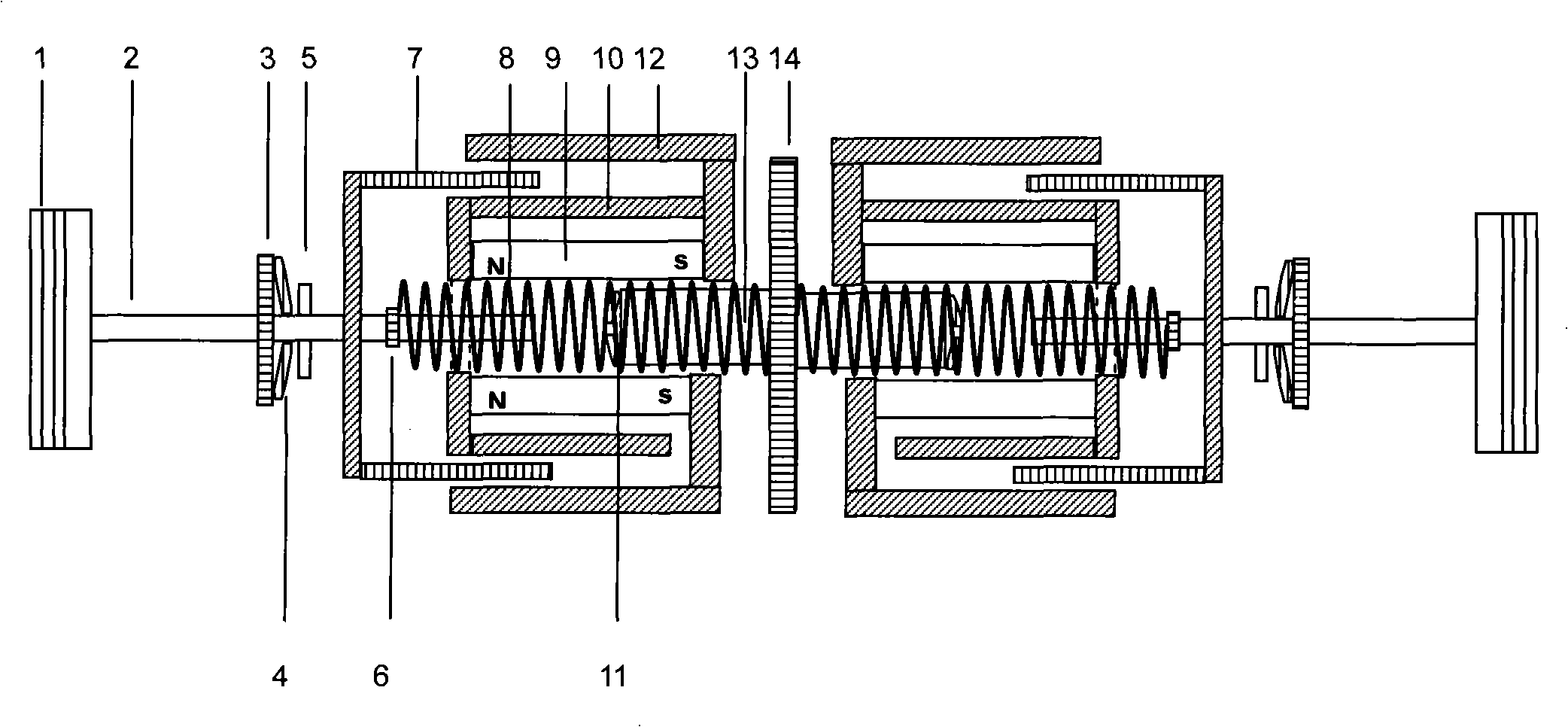

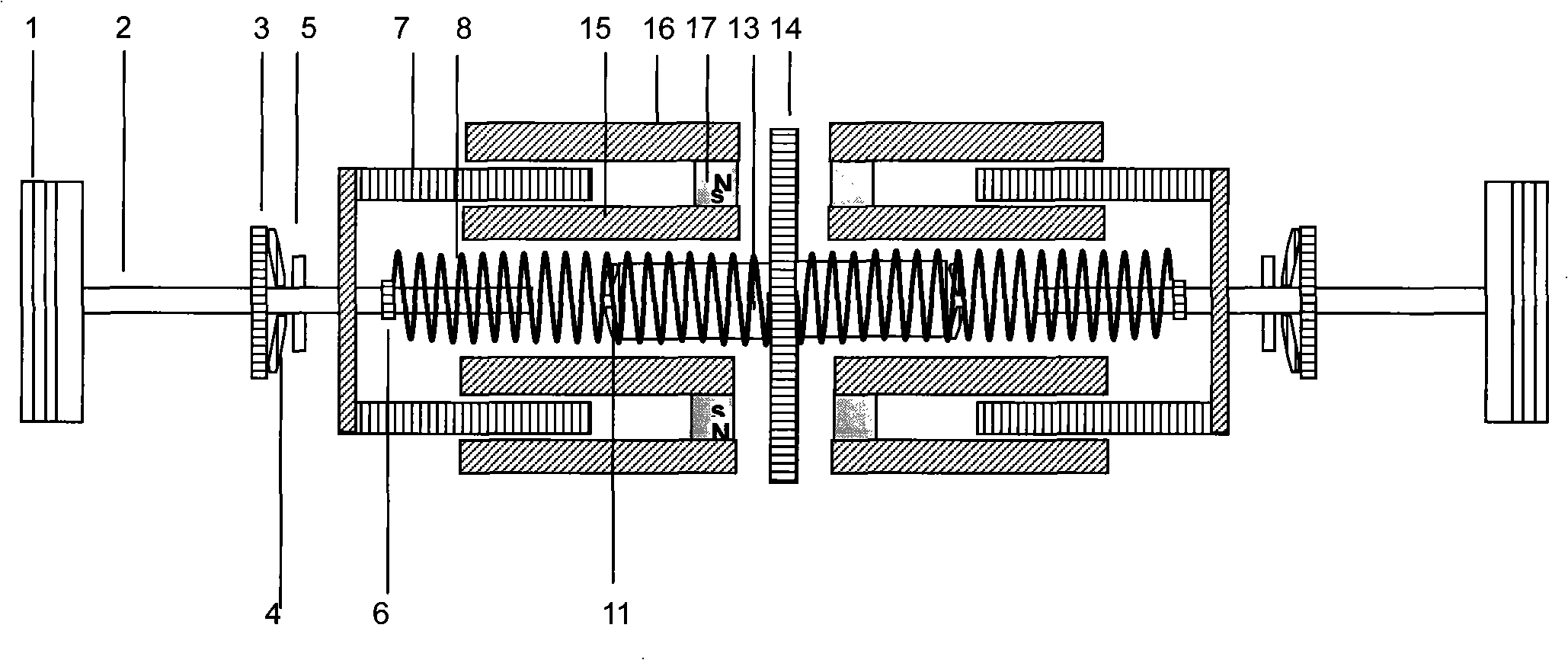

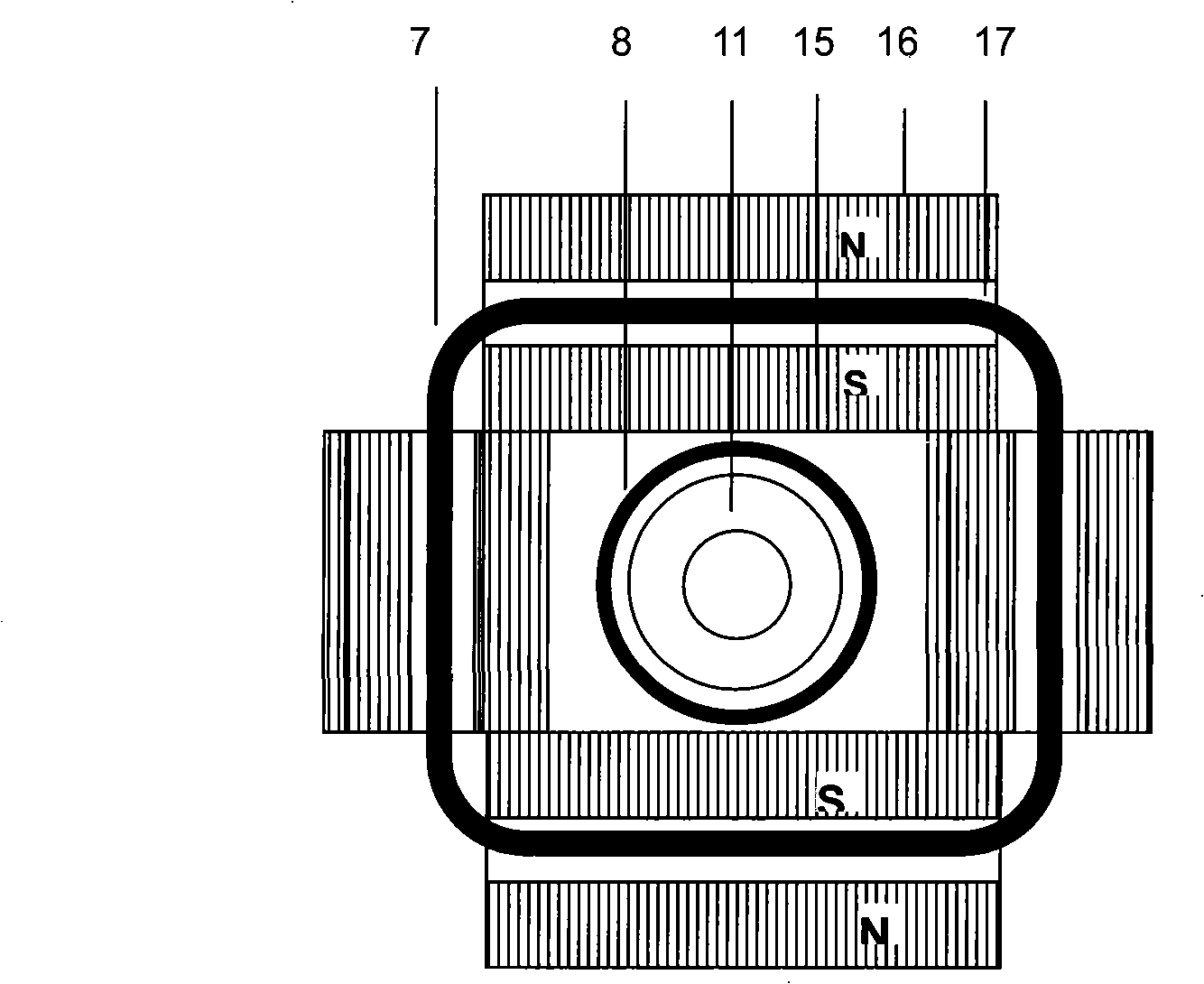

[0022] exist figure 1 Among them, the piston (1) is connected with the connecting rod (2), the force plate (5), the generator coil (7), the coil spring seat (6), and the coil spring (8), and the other end of the coil spring (8) is connected with the spring seat (14) connection, the disc spring (4) is connected with the spring seat (3), the spring seat (3) is fixed on the body, the central opening is slidably connected with the connecting rod (2), the disc spring (11) is connected with the disc spring The spring seat (13) is connected, and the disc spring seat (13) is designed as a column, mainly in order to reduce the length of the connecting rod and reduce the weight of the system. The permanent magnet (9) is hollow and is connected with the body axially. 10) and (12) form a magnetic field perpendicular to the axial direction, the reciprocating motion of the piston (1) drives the generator coil (7) to reciprocate in the magnetic field, and the balance position of the piston i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com