Battery cover plate with new type structure and secondary battery thereof

A technology of battery cover and new structure, applied in secondary battery manufacturing, structural parts, battery pack components and other directions, can solve the problems of unstable sealing, inconvenient external connection, reducing battery volume specific capacity, etc. Tightness and safety, flexible external connection and disassembly, and the effect of improving volumetric capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

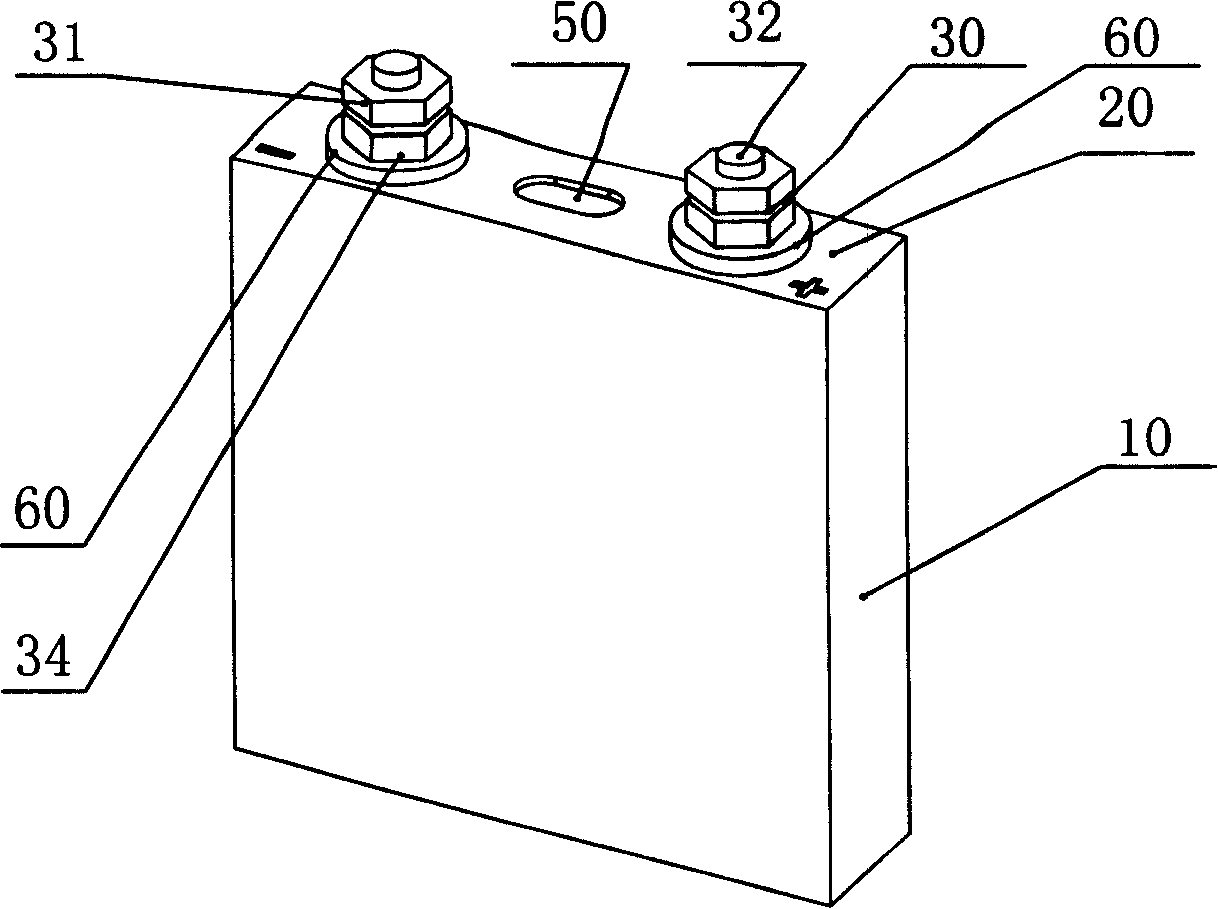

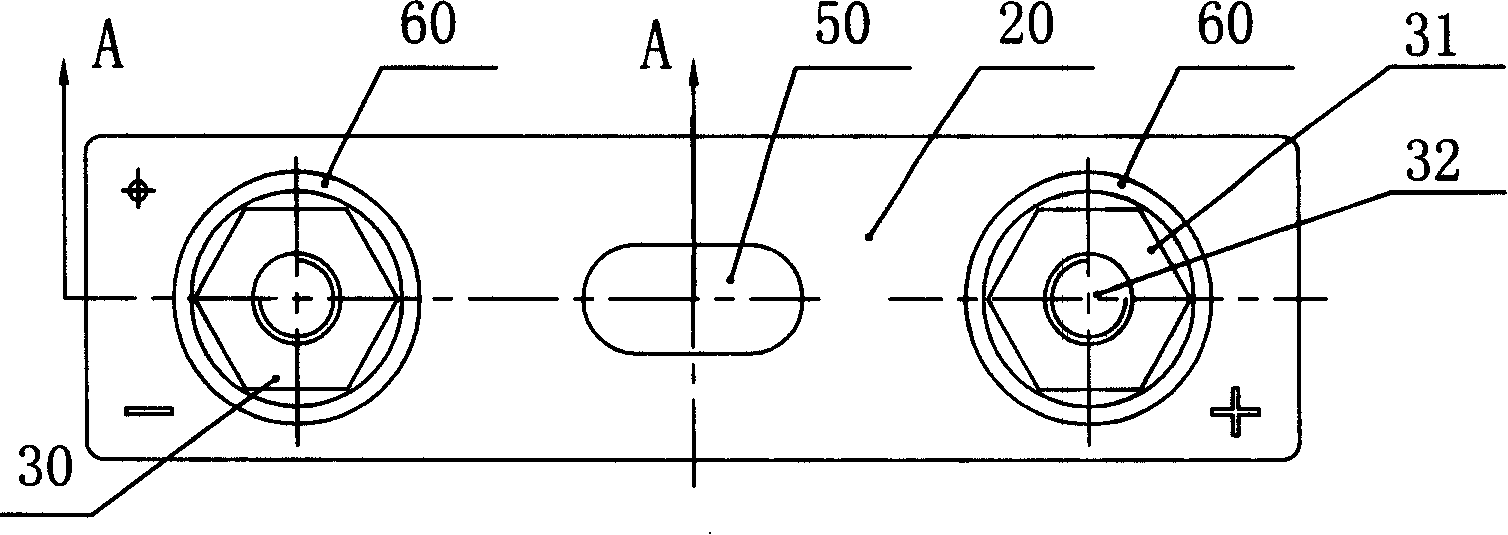

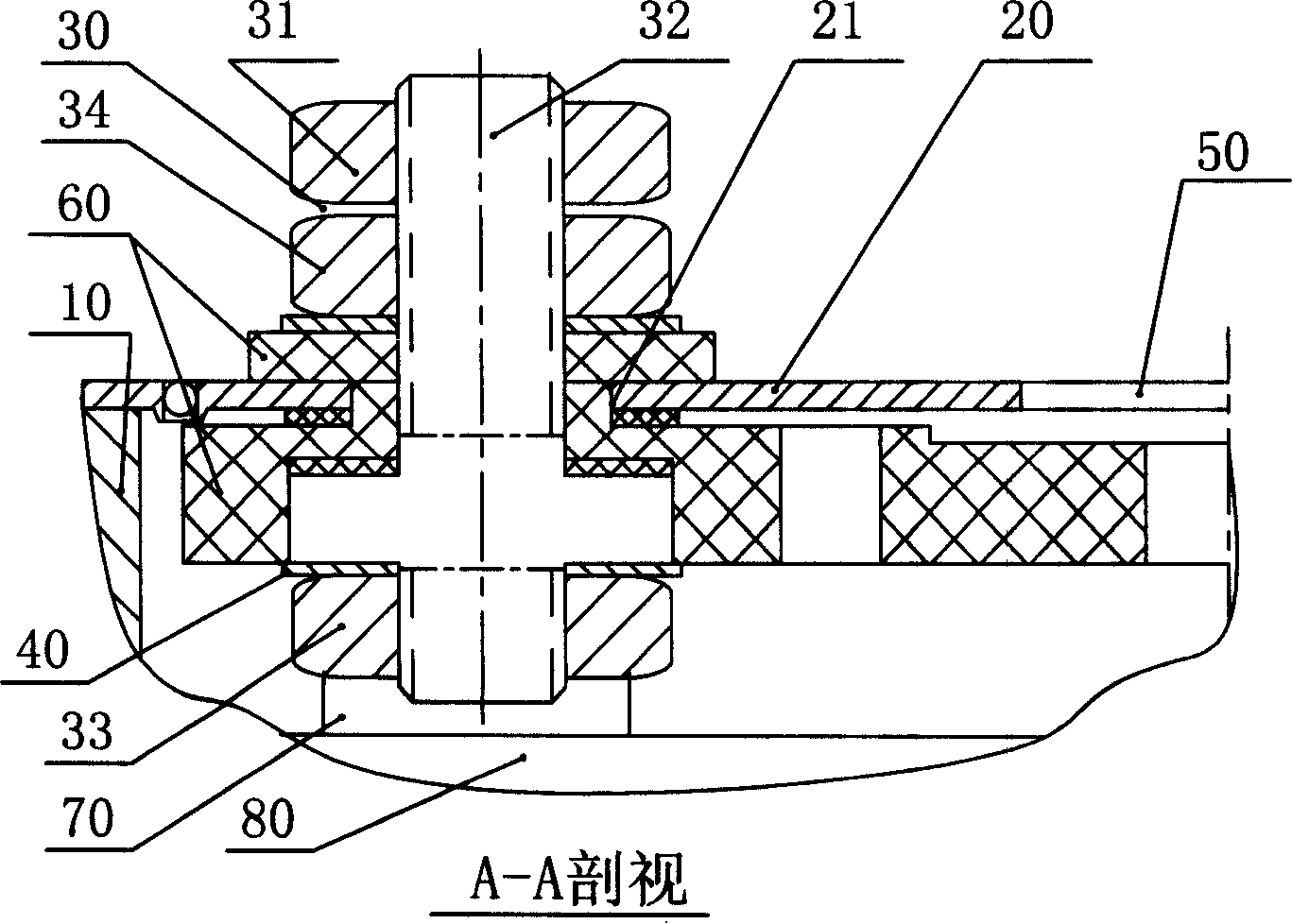

[0035] Such as Figure 7-9 , shown in order are the three-dimensional, top view and partial cross-sectional schematic diagrams of the secondary battery embodiment 1 of the present invention. The secondary battery includes a metal case 10, a battery cover plate, and the battery cover plate includes a plate body 20 with a through hole 21, a positive / negative electrode connector 30, a positive / negative conductive sheet 40, an explosion-proof device 50, and a lining on the through hole 21. The insulating washer 60 at the hole, the positive / negative electrode connectors 30 are respectively fixed on the plate body 20 by respective fasteners 35 and insulating washer 60, and the positive / negative conductive strips 40 are respectively connected to respective electrodes by the fasteners 35 The parts 30 are connected and fixed under the insulating washer 60 , the lower ends of the positive and negative conductive sheets 40 are respectively connected to the positive and negative tabs 70 ,...

Embodiment 2

[0039] Such as Figure 10 , 11 , shown in sequence are the top view and cross-sectional schematic diagrams of the battery cover plate in Example 2 of the present invention; Figure 12 , 13 It is a top view and a schematic cross-sectional view of the main body of the electrode pressure plate in Embodiment 2 of the present invention in sequence. The battery cover plate includes a plate body 20 with a through hole 21, a positive / negative electrode connector 30, a positive / negative conductive sheet 40, an explosion-proof device 50, an insulating gasket 60 lining the through hole 21, and a positive / negative electrode connection. Components 30 are respectively fixed on the plate body 20 through respective insulating washers 60, positive / negative conductive strips 40 are respectively connected with respective electrode connectors 30 through fasteners 35 and fixed under the insulating washers 60, and the electrodes are connected Part 30 includes fastener solid rivet 35 and electrod...

Embodiment 3

[0044] Such as Figure 14-15 , shown in sequence are the top view and cross-sectional schematic diagrams of the battery cover plate of Example 3 of the present invention; Figure 16-19 , which are the top view and cross-sectional view of the electrode pressure plate and the threaded connector in the third embodiment of the present invention. It can be seen from the above figure that the other structures are the same as in Embodiment 2 except that the threaded connectors on the electrode pressure plate 36 are lag bolts 390 and hex nuts 391 passing through the plate opening 361 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com