Positive slurry of lithium ion battery as well as preparation method and application of positive slurry of lithium ion battery

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of unsuitable mass production, complex mixing process, and high proportion of graphene, and achieve excellent charge-discharge cycle life and improve The effect of volume specific capacity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

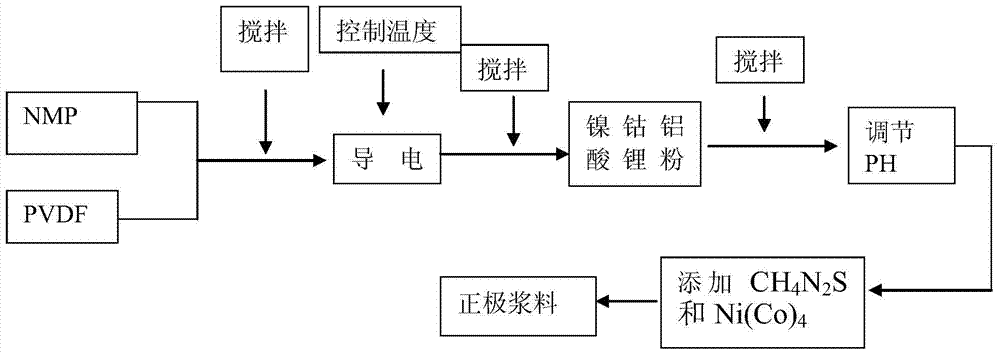

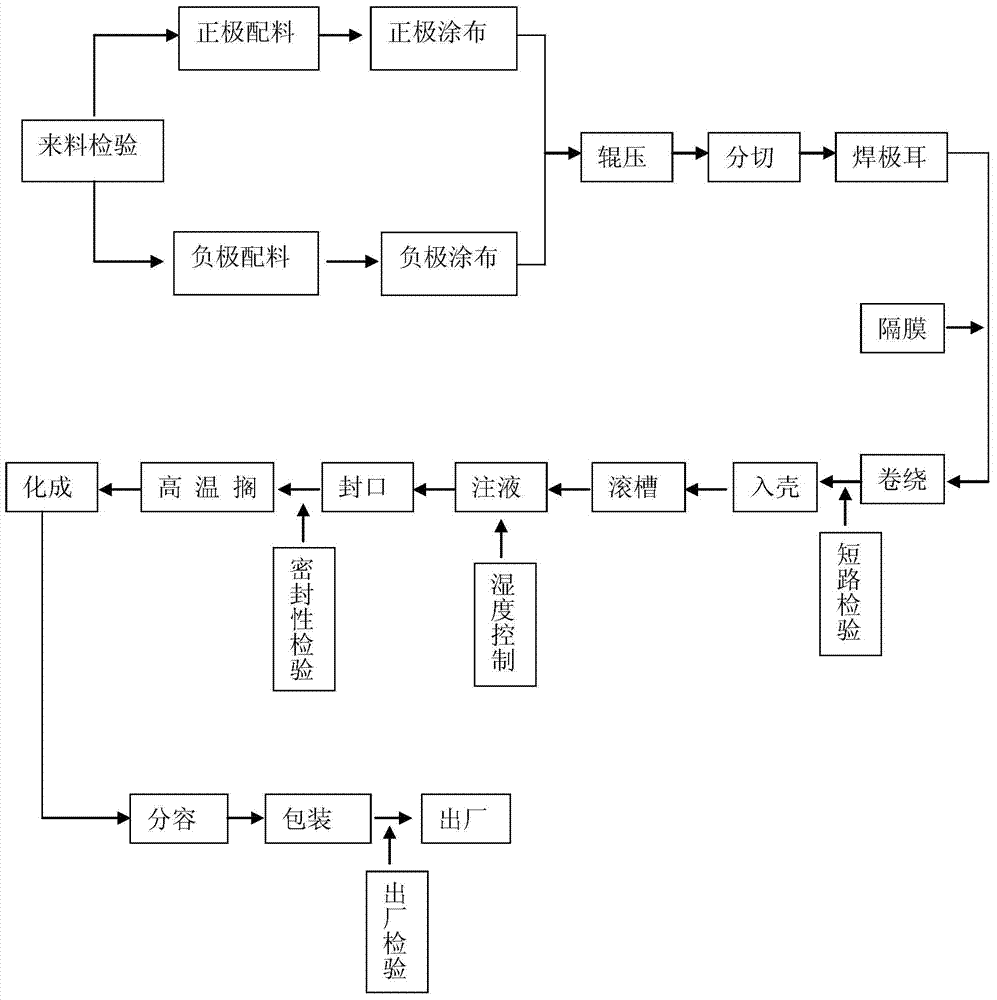

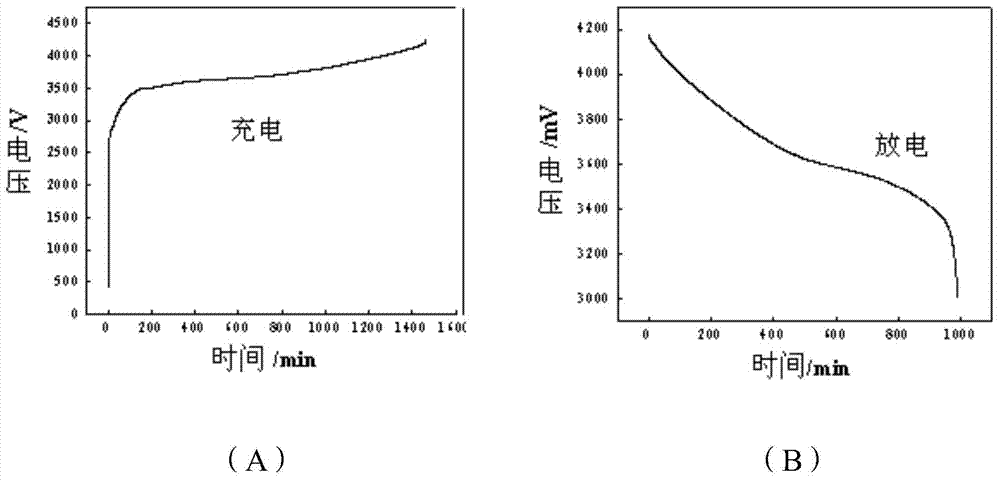

[0056] First add 625g of solvent and 15g of oily binder polyvinylidene fluoride (PVDF) into a high-speed mixer at a stirring speed of 3000r / min for 2 hours to obtain mixture A. While stirring, continue to add 15g of conductive agent to mixture A slowly and stir for 2 hours at a stirring speed of 3000r / min, using a water bath to control the reaction temperature at 25°C to obtain mixture B. Then slowly add 800g of nickel-cobalt-lithium-aluminate powder into the mixture B, and slowly add in 2 times during the addition. The stirring rate is 3000r / min, stirring for 1.5 hours, and slowly adding oxalic acid during the stirring until the pH value of the slurry is 8. Add thiourea (CH4N2S) and transition metal compound (Ni(Co)4) to the slurry by 5% of the total amount. Coat the above-mentioned positive electrode slurry on the aluminum foil current collector, use single-sided or double-sided coating during the coating process, and bake in a 15-meter oven at a baking temperature of 100 °...

Embodiment 2

[0062] Example 2: First, 610 g of solvent and 20 g of oily binder polyvinylidene fluoride (PVDF) were added to a high-speed mixer at a stirring speed of 4000 r / min for 3 hours to obtain mixture A. While stirring, continue to add 20g of conductive agent slowly to mixture A and stir for 3 hours at a stirring speed of 4000r / min, using a water bath to control the reaction temperature at 25°C to obtain mixture B. Subsequently, 1000 g of nickel-cobalt-lithium-aluminate powder was slowly added to the mixture B, and slowly added in 3 times during the addition. The stirring rate is 4000r / min, stirring for 3 hours, and slowly adding oxalic acid during the stirring until the pH value of the slurry is 9. Add thiourea (CH4N2S) and transition metal compound (Ni(Co)4) to the slurry by 8% of the total amount. Coat the above-mentioned positive electrode slurry on the aluminum foil current collector, use single-sided or double-sided coating during the coating process, and bake in a 15-meter ov...

Embodiment 3

[0063] Example 3: 590g of solvent and 27.7g of oily binder polyvinylidene fluoride (PVDF) were first added to a high-speed mixer at a stirring speed of 5000r / min for 4 hours to obtain mixture A. While stirring, continue to add 27.7g of conductive agent to mixture A slowly and stir for 4 hours at a stirring speed of 5000r / min, using a water bath to control the reaction temperature at 25°C to obtain mixture B. Then slowly add 1200g of nickel-cobalt-lithium-aluminate powder into the mixture B, and slowly add in 4 times during the addition. The stirring rate is 5000r / min, stirring for 1.5 hours, and slowly adding oxalic acid during the stirring until the pH value of the slurry is 9.5. Add thiourea (CH4N2S) and transition metal compound (Ni(Co)4) to the slurry by 10% of the total amount. Coat the above-mentioned positive electrode slurry on the aluminum foil current collector, use single-sided or double-sided coating during the coating process, and bake in a 15-meter oven at a bak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com