Lithium-ion secondary battery and its separator

A secondary battery and separator technology, applied in secondary batteries, battery components, circuits, etc., can solve problems such as poor electrolyte affinity, affecting the cycle performance of lithium-ion secondary batteries, rate performance, and low ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

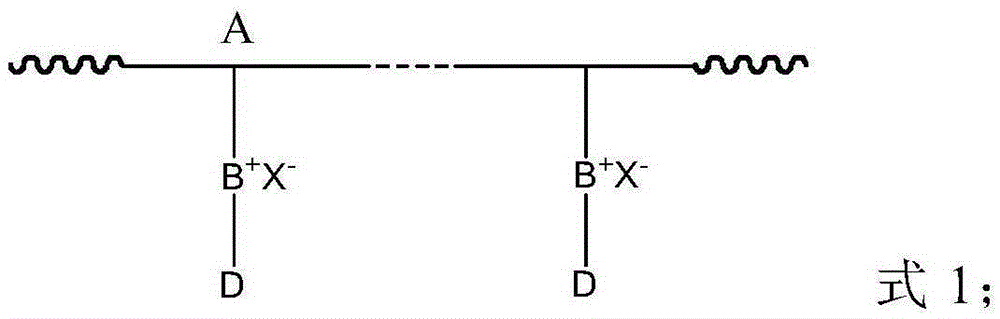

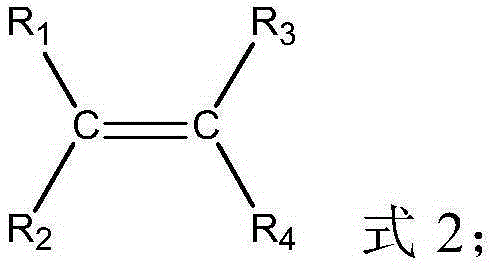

[0034] The first method for preparing a separator for a lithium ion secondary battery according to the second aspect of the present invention is used to prepare a separator having the structure of formula 1, comprising the steps of: (1) high-energy irradiation: irradiating a polymer substrate with High-energy irradiation is performed indoors to generate free radicals to obtain a polymer substrate with free radicals; (2) the first grafting: the polymer substrate with free radicals is immersed in a solution containing monomer B to carry out The first grafting reaction obtains the polymer substrate after the first grafting; (3) the second grafting: the polymer substrate after the first grafting is immersed in a solution containing halogenated hydrocarbons Carry out the second grafting reaction to obtain the polymer base material after the second grafting; (4) drying: drying the obtained polymer base material to obtain an isolation film, and the obtained isolation film has the stru...

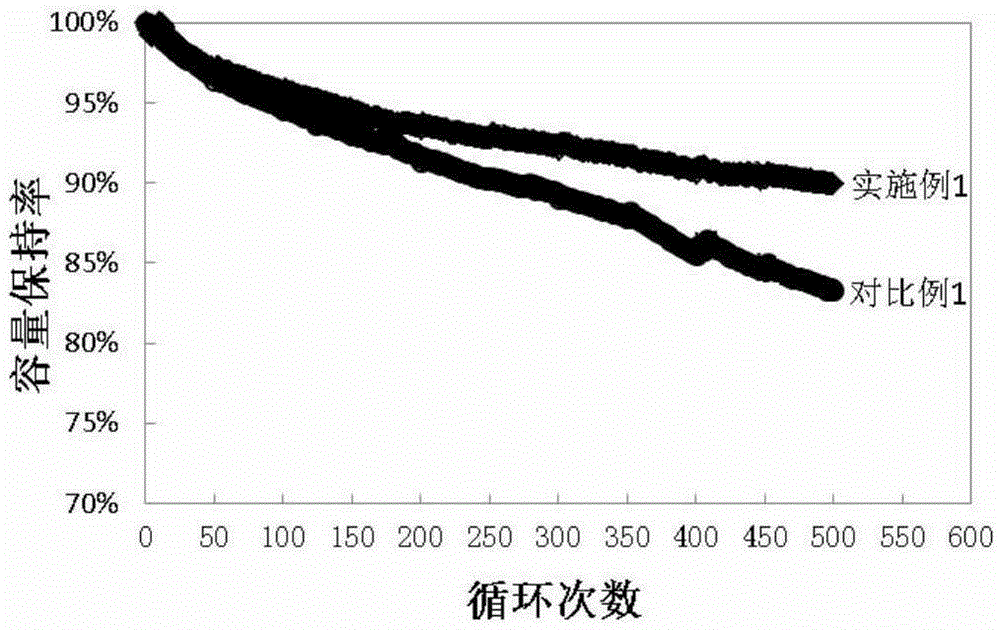

Embodiment 1

[0109] A Preparation of Separator for Lithium Ion Secondary Batteries

[0110] (1) Put the polymer-based polyethylene film after removing surface impurities 60 Irradiated in a Coγ-ray irradiation room with a dose of 65KGy to obtain a polyethylene film with free radicals;

[0111](2) Immerse the polyethylene film with free radicals in the N,N-dimethylformamide solution of vinylpyridine (monomer B) with a mass fraction of 50%, and after deoxidizing with nitrogen, at 60°C The reaction was carried out in a constant temperature water bath for 12 hours to obtain the polyethylene film after the first grafting. By weighing the quality of the polyethylene film before and after the grafting and taking the weight of the polyethylene film as 100%, the calculated grafting rate was 5.10%;

[0112] (3) Immerse the polyethylene film after the first grafting in the N,N-dimethylformamide solution of benzyl bromide (halogenated hydrocarbon) with a mass fraction of 37%, and react in a constant t...

Embodiment 2

[0124] A lithium ion secondary battery was prepared according to the method of Example 1, except that:

[0125] A Preparation of Separator for Lithium Ion Secondary Batteries

[0126] (1) The polymer substrate is polypropylene film, and the irradiation dose is 76KGy;

[0127] (2) Monomer B is vinylthiophene, the solvent used is N-methylpyrrolidone (NMP), the mass fraction of monomer B is 65%, the temperature of the constant temperature water bath is 80°C, the reaction time is 23h, and the graft ratio is is 5.90%;

[0128] (3) The halogenated hydrocarbon is biphenyl dichlorobenzyl, the solvent used is N-methylpyrrolidone (NMP), the mass fraction of the halogenated hydrocarbon is 35%, the temperature of the constant temperature water bath is 100°C, the reaction time is 20h, and then the The branch rate is 5.71%;

[0129] (4) Lithium salt is LiAsF 6 , the solvent used is ethylene carbonate, the mass fraction of lithium salt is 10%, the temperature of the constant temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com