Sodium alginate-based lithium battery diaphragm and preparation method thereof

A lithium battery diaphragm and sodium alginate technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as limiting ion conductivity, battery short circuit, size shrinkage, etc., achieve high ion conductivity and improve rate performance , Improve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

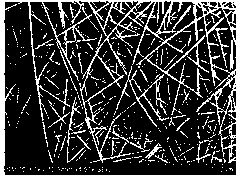

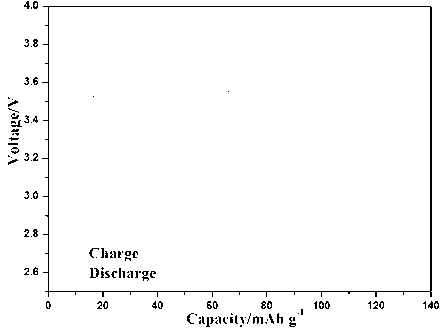

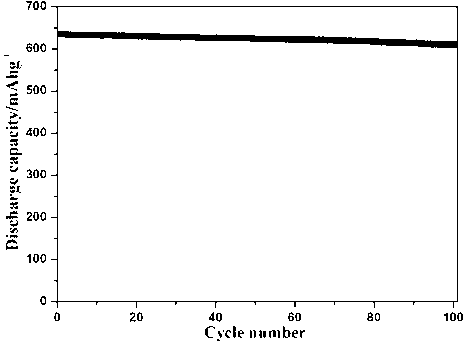

[0020] Weighed 1.5 g of sodium alginate and 1.5 g of polyethylene oxide and dissolved them in 97 g of deionized water, and stirred them magnetically for 2 h to obtain a uniform sodium alginate / polyethylene oxide mixed solution. Take 2 mL of the mixed solution and place it in a syringe with a needle with an inner diameter of 1.2 mm. Aluminum foil was used as the receiving device, and the preset spinning conditions were: a fixed voltage of 15 kV, a fixed distance of 10 cm, and a fixed solution flow rate of 0.5 mL / h. After spinning, the fiber membrane was compacted with a pressure of 8 MPa to obtain a sodium alginate / polyethylene oxide composite non-woven membrane with a thickness of 30 μm.

[0021]

Embodiment 2

[0023] Weighed 2 g of sodium alginate and 1 g of polyvinyl alcohol and dissolved them in 80 g of deionized water, and stirred for 3 h with magnetic force to obtain a uniform sodium alginate / polyvinyl alcohol mixed solution. Take 2.5 mL of the resulting mixed solution into a syringe with a needle inner diameter of 0.8 mm. Aluminum foil was used as the receiving device, and the preset spinning conditions were: a fixed voltage of 30 kV, a fixed distance of 15 cm, and a fixed solution flow rate of 1 mL / h. After spinning, the fiber membrane was compacted with a pressure of 10 MPa to obtain a polysodium alginate / polyvinyl alcohol composite nonwoven membrane with a thickness of 50 μm.

[0024]

Embodiment 3

[0026] Weighing 3 g sodium alginate, 2 g carrageenan and 2 g nano-silica were dissolved in 150 g deionized water, and stirred with magnetic force for 4 h to obtain a uniform sodium alginate / carrageenan / nano-silica mixture. solution. Take 4 mL of the resulting mixed solution into a syringe with a needle inner diameter of 1.6 mm. Aluminum foil was used as the receiving device, and the preset spinning conditions were: a fixed voltage of 25 kV, a fixed distance of 20 cm, and a fixed solution flow rate of 2 mL / h. After spinning, the fiber membrane was compacted with a pressure of 5 MPa to obtain a sodium alginate / carrageenan / nano-silica composite non-woven membrane with a thickness of 70 μm.

[0027] The present invention is not limited to the above embodiments, and can be prepared according to the material ratio, spinning voltage, spinning temperature, receiving distance, rolling pressure, rolling time and rolling temperature to meet the requirements of the lithium battery separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com