Preparation method for lithium iron phosphate materials with high tap density

A technology of lithium ferrous phosphate and tap density, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve problems such as difficult wide application, small volume-to-capacity ratio, and low tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

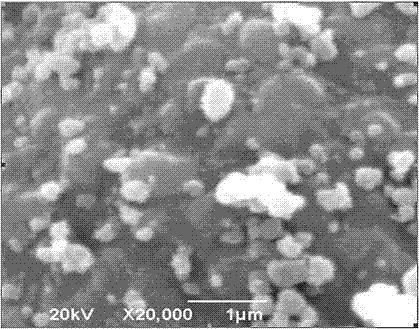

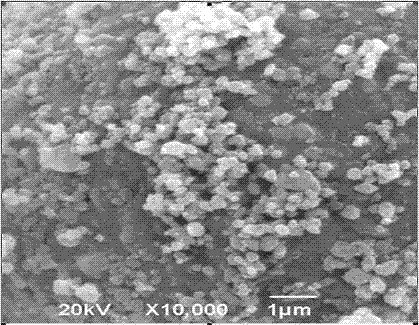

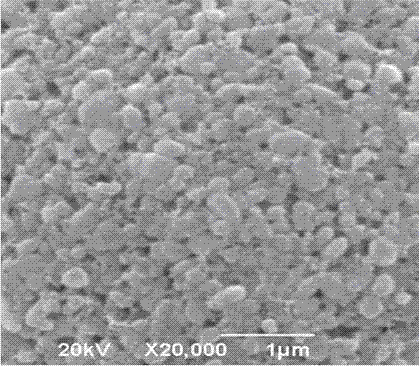

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation method of a kind of high tap density lithium iron phosphate material of this example, its steps are:

[0030] a. After mixing lithium salt, iron salt, and phosphorus salt according to the molar ratio of 1.05:1:1, add polyethylene glycol and nickel nitrate, and wet ball mill in a ball mill for 4 hours;

[0031] b. Using a centrifugal spray granulation dryer to spray-dry the raw material obtained in step a, the inlet temperature is 240°C, and the outlet temperature is 100°C to obtain a spherical precursor;

[0032] c. Put the precursor into a gas circulation furnace for sintering under the protection of nitrogen, pre-fire at 400°C for 5 hours and cool to room temperature to obtain a pre-sintered product;

[0033] d. The pre-sintered product was sintered under the protection of nitrogen, the sintering temperature was 680°C, and the temperature was kept constant for 5h to cool to room temperature to obtain LiFePO 4 / C;

[0034] e. The Li...

Embodiment 2

[0037] Embodiment 2: the preparation method of a kind of high tap density lithium iron phosphate material of this example, its steps are:

[0038] a. After mixing lithium salt, iron salt, and phosphorus salt according to the molar ratio of 1.05:1:1, add polyethylene glycol and nickel nitrate, and wet ball mill in a ball mill for 4 hours;

[0039] b. Using a centrifugal spray granulation dryer to spray-dry the raw material obtained in step a, the inlet temperature is 240°C, and the outlet temperature is 100°C to obtain a spherical precursor;

[0040] c. Put the precursor into a gas circulation furnace for sintering under the protection of nitrogen, pre-fire at 400°C for 5 hours and cool to room temperature to obtain a pre-sintered product;

[0041] d. The pre-sintered product was sintered under the protection of nitrogen, the sintering temperature was 680°C, and the temperature was kept constant for 5h to cool to room temperature to obtain LiFePO 4 / C;

[0042] e. The Li...

Embodiment 3

[0044] Embodiment 3: the preparation method of a kind of high tap density lithium iron phosphate material of this example, its steps are:

[0045] a. After mixing lithium salt, iron salt, and phosphorus salt according to the molar ratio of 1:1:1, add polyethylene glycol and nickel nitrate, and wet ball mill in a ball mill for 4 hours;

[0046] b. Using a centrifugal spray granulation dryer to spray-dry the raw material obtained in step a, the inlet temperature is 240°C, and the outlet temperature is 100°C to obtain a spherical precursor;

[0047] c. Put the precursor into a gas circulation furnace for sintering under the protection of nitrogen, pre-fire at 400°C for 5 hours and cool to room temperature to obtain a pre-sintered product;

[0048]d. The pre-sintered product was sintered under the protection of nitrogen, the sintering temperature was 680°C, and the temperature was kept constant for 5h to cool to room temperature to obtain LiFePO 4 / C;

[0049] e. The LiFePO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com